Magnetic TiO2/Fe3O4/C composite photocatalyst, and preparation method and application thereof

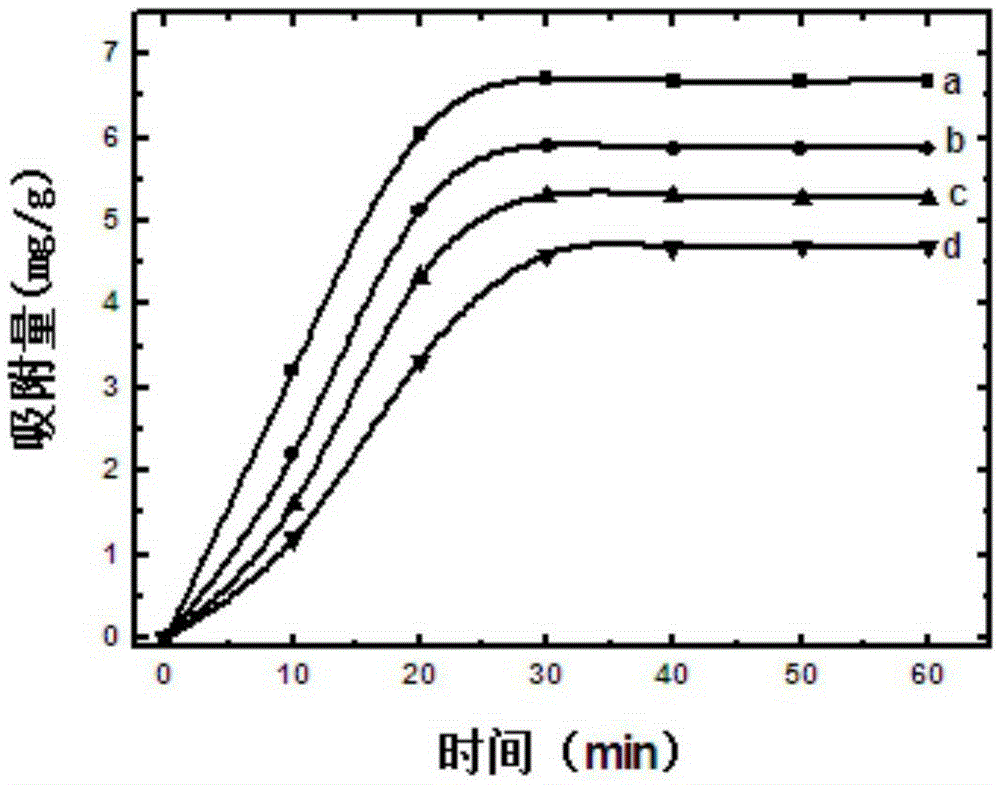

A composite photocatalyst technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc. Problems such as low utilization rate, to achieve the effect of improving recovery rate, enhancing photocatalytic performance and service life, and speeding up the rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

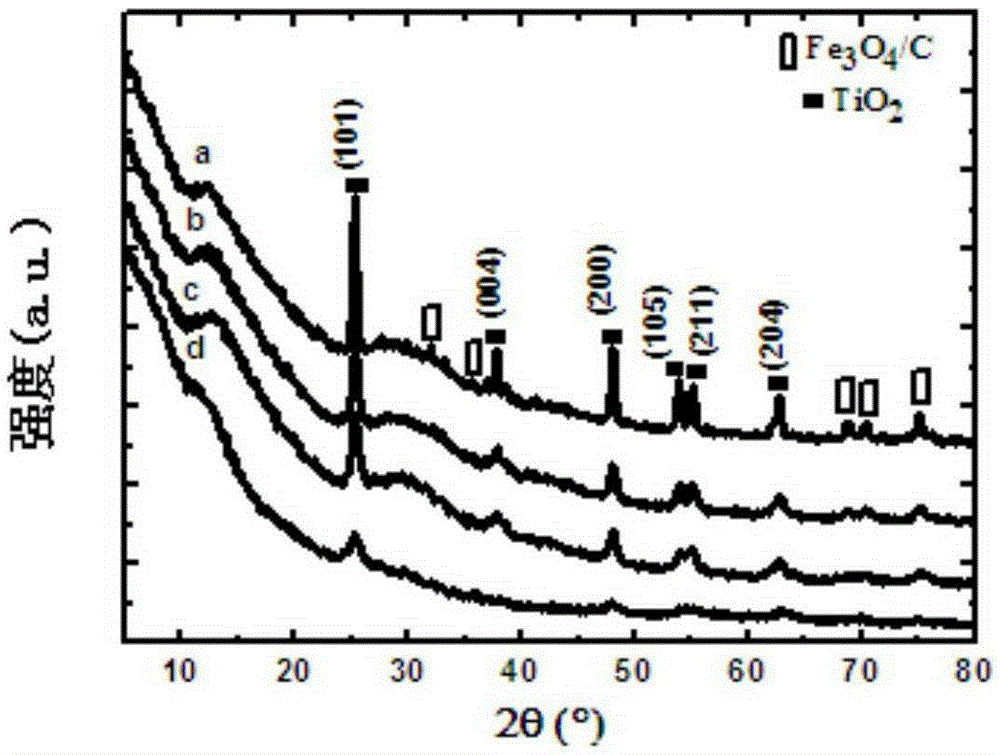

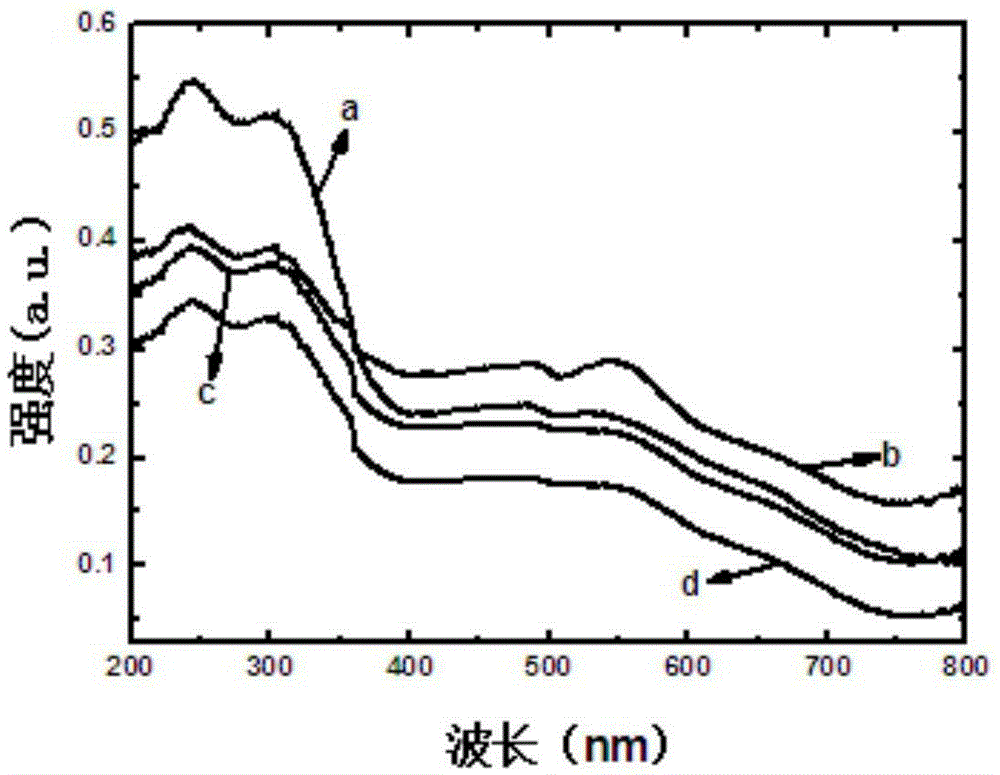

Examples

Embodiment 1

[0035] S1: Magnetic Fe 3 o 4 / Yeast preparation:

[0036] Weigh 22.5mL of ethylene glycol and 22.5mL of diethylene glycol and mix thoroughly, then add 0.1g of saccharomyces, 2.4g of ferric chloride (FeCl 3 ·6H 2 (2), 3.4g sodium acrylate and 3.4g sodium acetate, after ultrasonic reaction for 1h, transfer the uniform black reaction solution to a polytetrafluoroethylene-lined stainless steel autoclave, seal, heat to a temperature of 200°C for 10h, and the reaction ends After cooling to room temperature, the magnetic Fe was obtained after filtering, washing with ethanol and water for 3 times, and vacuum drying at 65°C for 10 h. 3 o 4 / yeast;

[0037] S2: Magnetic TiO 2 / Fe 3 o 4 / Yeast preparation:

[0038] Measure and mix 36mL of absolute ethanol, 3mL of deionized water and 1mL of concentrated hydrochloric acid to obtain a mixture A; put 36mL of absolute ethanol and 10mL of tetra-n-butyl titanate into a three-necked flask, and stir at 40°C for 15 minutes to obtain a m...

Embodiment 2

[0042] Step S1 and step S2 are the same as described in Embodiment 1,

[0043] S3: Magnetic TiO 2 / Fe 3 o 4 Preparation of / C:

[0044] Take 2g magnetic TiO 2 / Fe 3 o 4 / Yeast is placed in a tube furnace and calcined at a temperature of 400°C for 3h, the heating rate is 2°C / min, and N is fed throughout the calcination 2 Protection, after cooling, the product TiO is obtained 2 / Fe 3 o 4 / C-400.

Embodiment 3

[0046] Step S1 and step S2 are the same as described in Embodiment 1,

[0047] S3: Magnetic TiO 2 / Fe 3 o 4 Preparation of / C:

[0048] Take 2g magnetic TiO 2 / Fe 3 o 4 / Yeast is placed in a tube furnace, calcined at a temperature of 500°C for 3 hours, the heating rate is 2°C / min, and N is fed throughout the calcining 2 Protection, after cooling, the product TiO is obtained 2 / Fe 3 o 4 / C-500.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com