Equipment for removal of multiple pollutants in waste gas of setting machine and in-situ regeneration of adsorbent and method of equipment

An in-situ regeneration and adsorbent technology, applied in the field of resources and environment, can solve the problems of affecting the appearance, unable to meet the requirements of new standards, no VOCs control unit, etc., to improve the appearance, avoid operating costs and solid waste, and reduce waste water generation. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle of the present invention, some improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

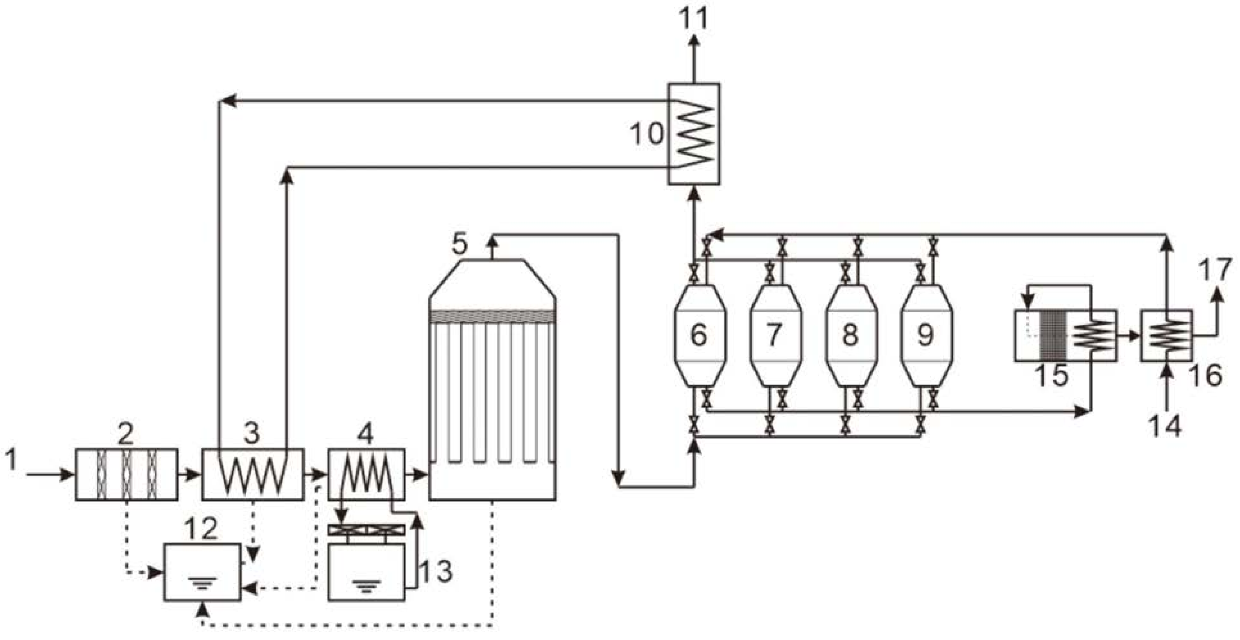

[0031] The device for removing multi-pollutants from the waste gas of the setting machine and in-situ regeneration of the adsorbent is used in the field of air pollution prevention and control. VOCs, and the amount of waste water and solid waste is extremely small, and the waste heat of exhaust gas can be used to eliminate "white smoke", which has good economic benefits and application prospects.

[0032] The device mainly includes a dust removal and oil fume rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com