Regeneration method of microchannel reactor Fischer-Tropsch synthesis catalyst

A technology of microchannel reactor and Fischer-Tropsch synthesis, applied in the direction of catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high energy consumption and high material consumption in the regeneration process, and achieve small damage, Good performance recovery and avoid damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

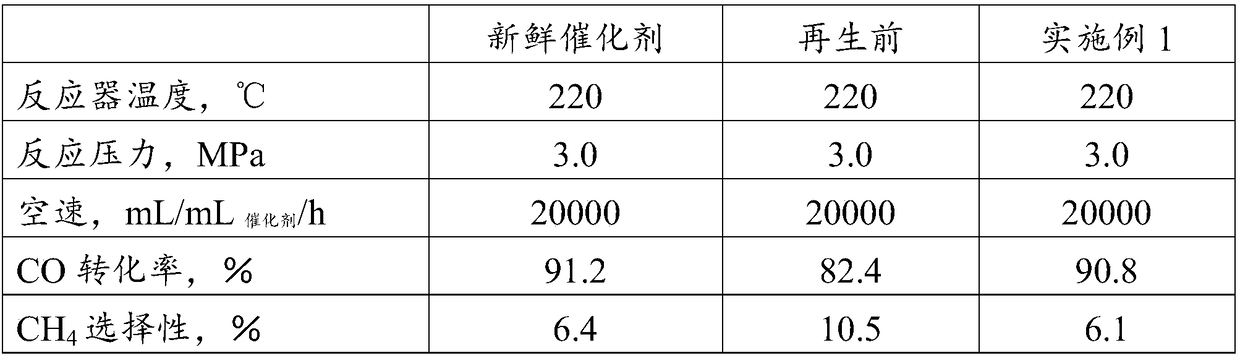

Embodiment 1

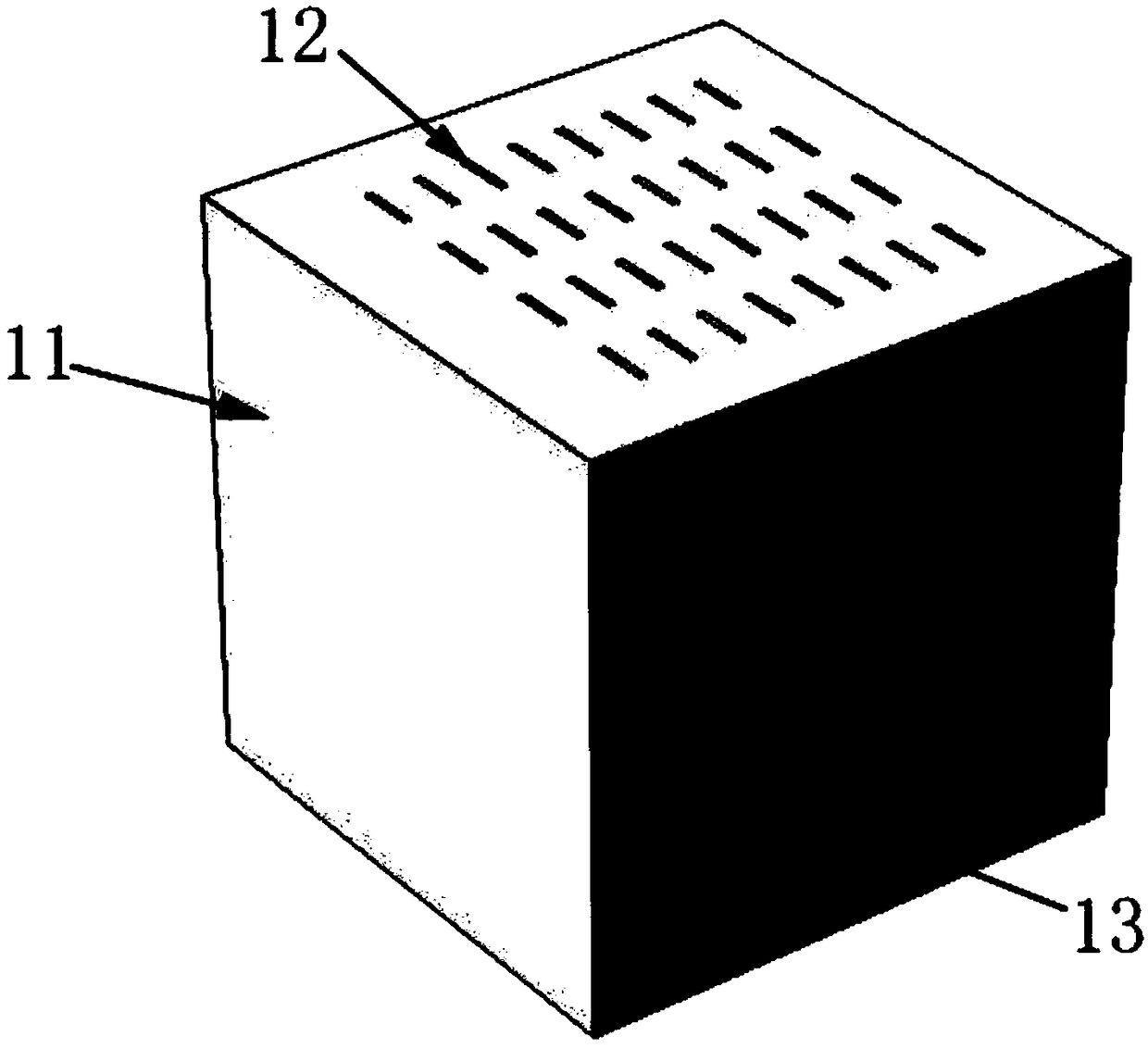

[0034] Such as figure 1 As shown, the microchannel reactor 11 comprises 8 layers of reaction channels 12 arranged side by side and 9 layers of heat transfer medium channels 13 arranged side by side, each reaction channel is 10 mm wide, 1 mm high, and 100 mm long, and each layer has 4 reaction channels 12 . Each heat conduction medium channel has a width of 10 mm, a height of 1 mm, and a length of 100 mm, and each layer has six heat conduction medium channels 13 . The reaction channel 12 and the heat transfer medium channel 13 intersect at 90°. The cobalt-based supported Fischer-Tropsch synthesis catalyst is loaded in the reaction channel 12 .

[0035] The preparation process of the cobalt-based supported Fischer-Tropsch synthesis catalyst used in the present embodiment is as follows: get alumina powder, add distilled water dropwise to incipient wetness, write down the volume of consumed water, then press Co content (oxide) 27% by weight % calculation, a cobalt nitrate impreg...

Embodiment 2

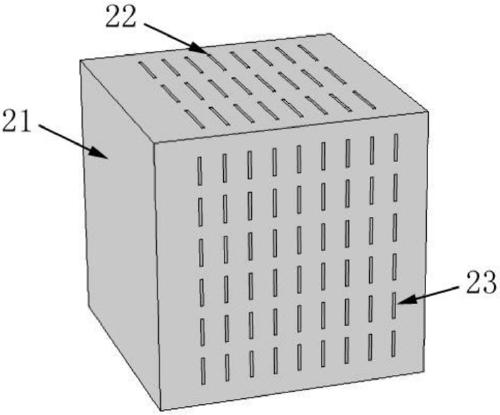

[0043] Such as figure 2 As shown, the microchannel reactor 21 comprises 8 layers of reaction channels 22 arranged side by side and 9 layers of heat transfer medium channels 23 arranged side by side, each reaction channel 22 is 20 mm wide, 1 mm high, and 100 mm long, and each layer has 3 reaction channels 22 . Each heat conduction medium channel 23 has a width of 10 mm, a height of 1 mm, and a length of 100 mm, and each layer has six heat conduction medium channels 23 . The reaction channel 22 and the heat transfer medium channel 23 intersect at 90°. A catalyst support coated with a cobalt-based supported Fischer-Tropsch synthesis catalyst is loaded in the reaction channel 22 .

[0044] The cobalt-based Fischer-Tropsch synthesis catalyst used in this example is a coated monolithic catalyst, and the preparation process is as follows: the cobalt-based supported catalyst is coated on a treated corrugated stainless steel support body, the support body is 18 mm wide, 0.8 mm high,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com