Electrochemical method for preparing activated carbon fibers with photocatalysis function

A technology of activated carbon fiber and photocatalysis, applied in physical/chemical process catalysts, chemical instruments and methods, other chemical processes, etc., can solve the problems of harsh operating conditions, high consumption, low efficiency, etc., to reduce manpower and ease supply. insufficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1) The activated carbon fibers with electrical conductivity and resistivity less than 80kΩ / m are boiled and cleaned with 2% hydrochloric acid, then washed to neutral by distillation, and dried in an oven for 24 hours;

[0021] 2) Soak the activated carbon fiber in step 1) in a N,N dimethylformamide solution of 0.05mol / L dicyandiamide for 24 hours;

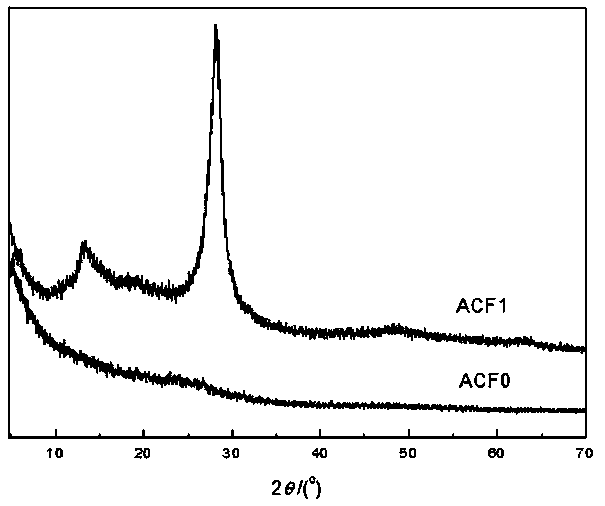

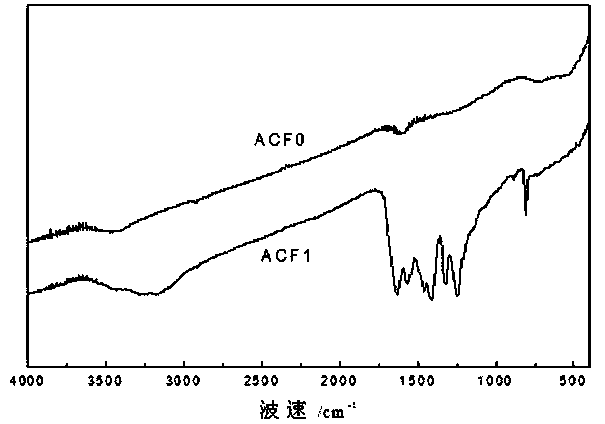

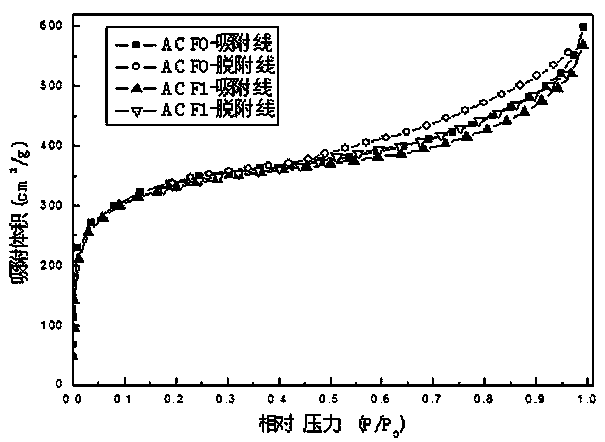

[0022] 3) The process of immobilizing graphite-phase carbon nitride is carried out in an electrolytic cell. Electrochemical deposition conditions: use 0.05mol / L dicyandiamine N,N dimethylformamide solution as electrolyte, graphite as anode, The activated carbon fiber in step 2) is used as the cathode, the power supply is a DC power supply, the electrolysis process voltage is 2000V, the electrolysis process temperature is 25°C, and the electrolysis time is 1h.

[0023] 4) Take out the active carbon fiber of the cathode from the electrolytic cell, wash it fully with distilled water, and dry it, so that the active carbon fiber ...

Embodiment 2

[0025] 1) The activated carbon fibers with electrical conductivity and resistivity less than 80kΩ / m are boiled and cleaned with 2% hydrochloric acid, then washed to neutral by distillation, and dried in an oven for 24 hours;

[0026] 2) Soak the activated carbon fiber in step 1) in 0.15mol / L N,N dimethylformamide solution of dicyandiamide for 24h;

[0027] 3) The process of immobilizing graphite phase carbon nitride is carried out in an electrolytic cell, and the electrochemical deposition conditions are as follows: 0.15mol / L N,N dimethylformamide solution of dicyandiamine is used as the electrolyte, and graphite is used as the anode. The activated carbon fiber in step 2) is used as the cathode, the power supply is a DC power supply, the electrolysis process voltage is 500V, the electrolysis process temperature is 30°C, and the electrolysis time is 5h.

[0028] 4) Take out the active carbon fiber of the cathode from the electrolytic cell, wash it fully with distilled water, an...

Embodiment 3

[0030] 1) The activated carbon fibers with electrical conductivity and resistivity less than 80kΩ / m are boiled and cleaned with 2% hydrochloric acid, then washed to neutral by distillation, and dried in an oven for 24 hours;

[0031] 2) Soak the activated carbon fiber in step 1) in 0.10mol / L N,N dimethylformamide solution of dicyandiamide for 24h;

[0032] 3) The process of immobilizing graphite-phase carbon nitride is carried out in an electrolytic cell. Electrochemical deposition conditions: use 0.10mol / L dicyandiamide N,N dimethylformamide solution as electrolyte, graphite as anode, The activated carbon fiber in step 2) is used as the cathode, the power supply is a DC power supply, the electrolysis process voltage is 1000V, the electrolysis process temperature is 28°C, and the electrolysis time is 3h.

[0033] 4) Take out the active carbon fiber of the cathode from the electrolytic cell, wash it fully with distilled water, and dry it, so that the active carbon fiber with ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com