Chlorella-containing 3D printed wire and preparation method thereof

A 3D printing and chlorella technology, applied in the field of materials, can solve the problems of cumbersome preparation process of porous adsorption materials, difficult processing, secondary pollution, etc., and achieve the effect of solving subsequent recycling problems, reducing environmental burden, and high printing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

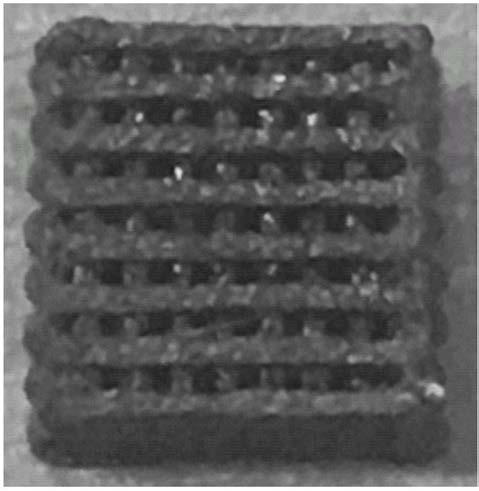

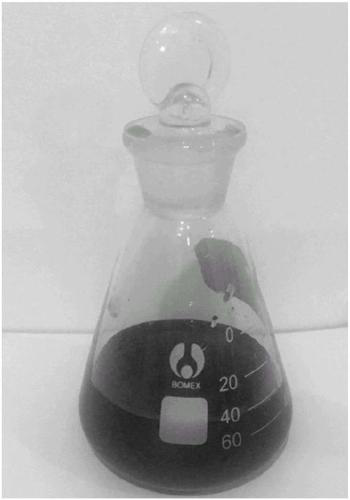

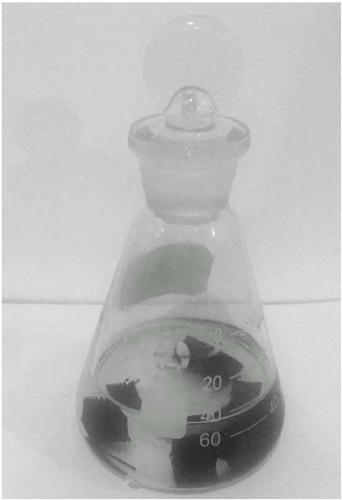

Image

Examples

Embodiment 1

[0036] A kind of wire rod containing chlorella 3D printing, is characterized in that, is made up of the following component by weight percentage:

[0037] Polylactic acid (PLA) 70

[0038] High Protein Chlorella 29.95

[0039] White oil 0.05

[0040] A preparation method of the described chlorella-containing 3D printing wire comprises the following steps:

[0041] A. Vacuum dry PLA (700g) and high-protein chlorella (299.5g) for 12 hours respectively;

[0042] B. According to the weight percentage formula, weigh the dried PLA (700g), high-protein chlorella (299.5g) and white oil (0.5g);

[0043] C. Place the weighed components in a high-speed kneader, keep the rotating speed at 1000rpm / min, and stir at high speed for 5min;

[0044] D. Put the above-mentioned fully mixed and uniform raw materials into the twin-screw extruder, and set the extrusion temperature at 110°C, 120°C, 135°C, 160°C, 175°C, 175°C, 170°C, 165°C, 160°C, At 155°C, melt and plasticize in the twin-screw me...

Embodiment 2

[0051] A kind of wire rod containing chlorella 3D printing, is characterized in that, is made of following component by weight percentage:

[0052] Polybutylene succinate (PBS) 78

[0053] Chlorella elegans 21.8

[0054] White oil 0.2

[0055] A preparation method for 3D printing wire containing chlorella comprises the following steps:

[0056] A. Vacuum-dry PBS (780g) and Chlorella escheri (218g) for 12 hours respectively;

[0057] B. According to the weight percentage formula, weigh the dried PBS (780g), Chlorella escheri (218g) and white oil (2g);

[0058] C. Place the weighed components in a high-speed kneader, keep the rotating speed at 2000rpm / min, and stir at a high speed for 6min;

[0059] D. Put the above-mentioned fully mixed and uniform raw materials into the twin-screw extruder, and set the extrusion temperature at 98, 105°C, 110°C, 120°C, 130°C, 132°C, 125°C, 125°C, 120°C, 110°C ℃, melt and plasticize in the twin-screw melting cavity and extrude the raw mater...

Embodiment 3

[0066] A kind of wire rod containing chlorella 3D printing, is characterized in that, is made of following component by weight percentage:

[0067] Acrylonitrile-butadiene-styrene (ABS) 65

[0068] Chlorella kelvin 34.7

[0069] White oil 0.3

[0070] A preparation method for 3D printing wire containing chlorella comprises the following steps:

[0071] A. Vacuum-dry ABS (650g) and Chlorella kesleri (347g) for 12 hours respectively;

[0072] B. According to the weight percentage formula, weigh the dried ABS (650g), Chlorella kesleri (347g) and white oil (3g);

[0073] C. Place the weighed components in a high-speed kneader, keep the rotating speed at 2000rpm / min, and stir at a high speed for 6min;

[0074] D. Put the above-mentioned fully mixed and uniform raw materials into the twin-screw extruder, and set the extrusion temperature at 195°C, 200°C, 205°C, 215°C, 220°C, 230°C, 235°C, 235°C, 230°C, Melt and plasticize in the twin-screw melting cavity and extrude the raw mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com