Device and method for converting organic sulfur in blast furnace gas and method for regenerating organic sulfur conversion catalyst

A technology of a reforming device and blast furnace gas, which is applied in the field of blast furnace gas desulfurization, can solve the problems of high labor transportation cost, large pressure drop value, fast catalyst deactivation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

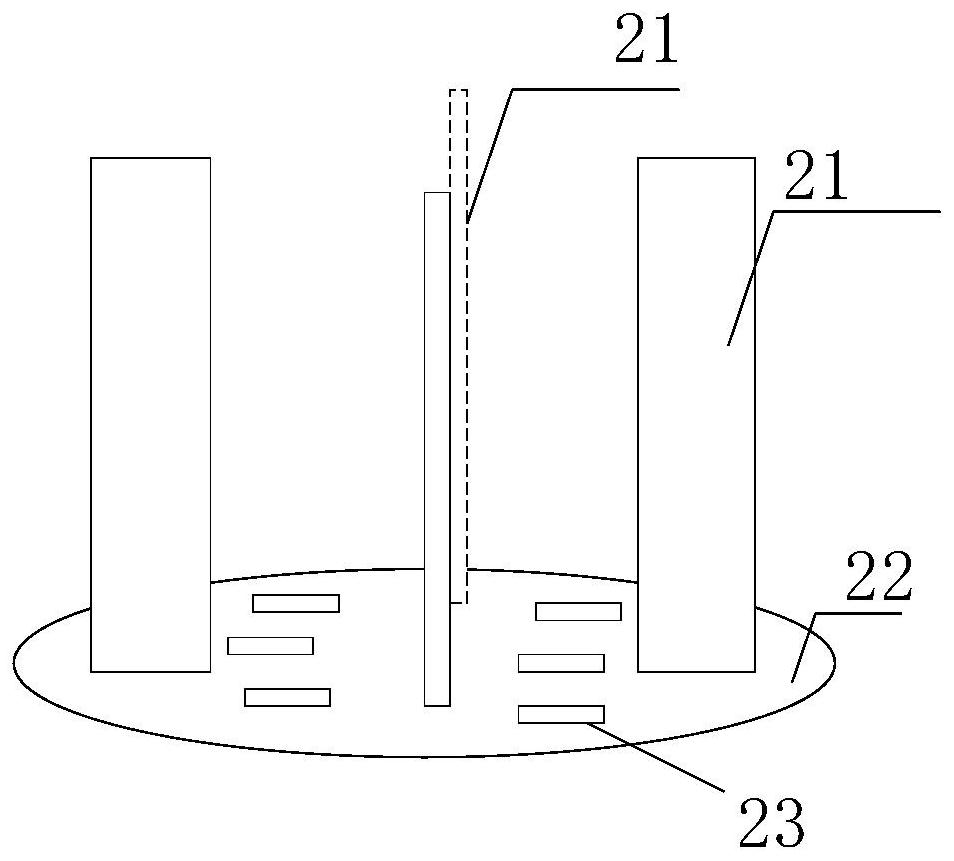

[0060] A preferred embodiment, one end of the rib in the gas distributor is a fixed connection, such as welding, and the other end and the gas inlet connection of the reactor are also fixed, such as welding.

[0061] Another preferred embodiment, the connection of one end of the rib in the gas distributor is a fixed connection, such as welding; the connection of the other end of the rib and the gas inlet of the reactor is removable, For example, hook. This connection method is used, which is more convenient for the loading and unloading of the catalyst.

[0062] According to the present invention, preferably, the diameter ratio of the disc in the diameter of the reactor is from 1 to 5: 1, preferably from 1 to 3: 1. Preferred conditions are used, more advantageous to uniformly distribute the blast furnace gas in the surface of the catalyst bed, and improve the catalyst efficiency of the catalyst.

[0063] Preferably, a hole is provided on the disc; further preferably, the opening r...

Embodiment 1

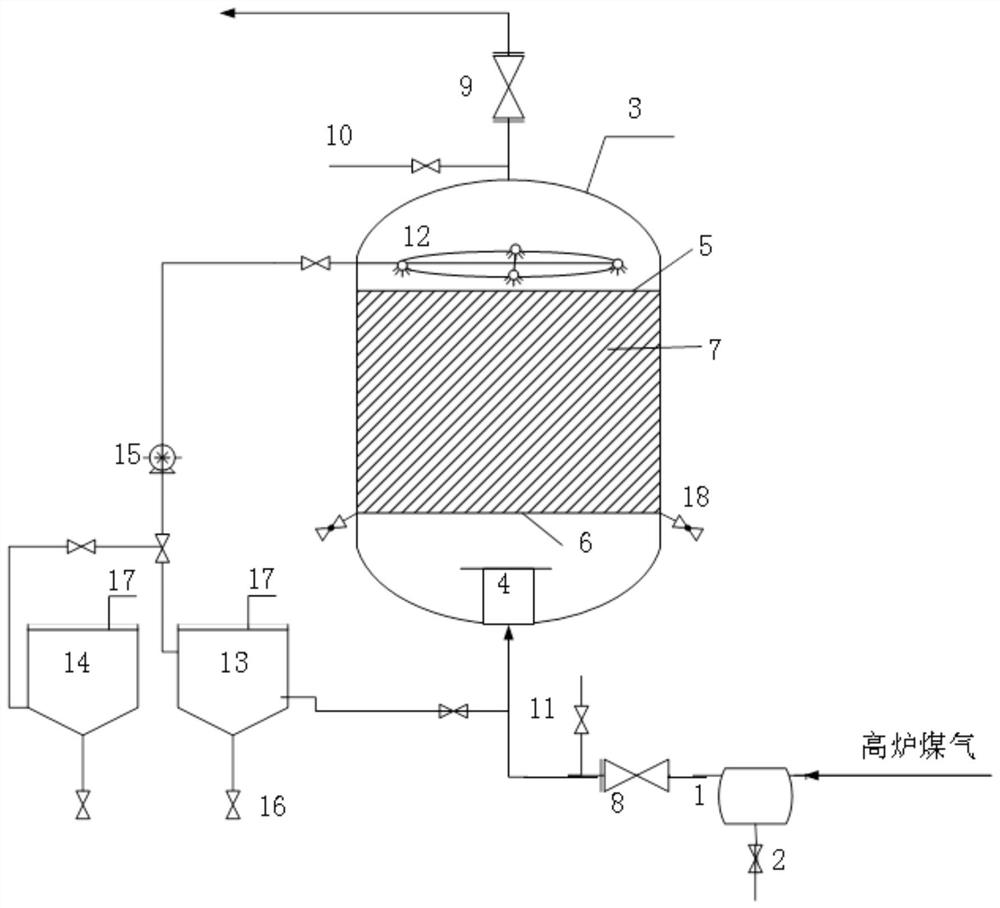

[0144] (1) Blast furnace gas organic sulfur conversion device, such as figure 1 As shown, the conversion device includes: a liquid distribution package 1, a guide valve 2, a reactor 3, a spray regeneration system, a reactor 3 (downward) including a gas distributor 4, an upper grid assembly 5, a lower layer Grid assembly 6, an organic sulfur conversion catalyst bed 7, an inlet shutoff valve 8, an outlet shutoff valve 9, a purge line inlet 10, a purge line outlet 11, a catalyst discharge port 18.

[0145]The spray regeneration system includes a regenerative liquid storage tank 14 mounted outside the reactor 3, a cleaning liquid storage tank 13, a pump 15, a delivery line, a tap water line 17, a bottom valve 16, and an interior mounted to reactor 3. The spray regeneration line 12 and the nozzle 27 disposed on the spray regeneration line 12, wherein the spray regeneration line 12 is each in line with the regenerative liquid storage tank 14 and the cleaning liquid storage tank 13, and ...

Embodiment 2

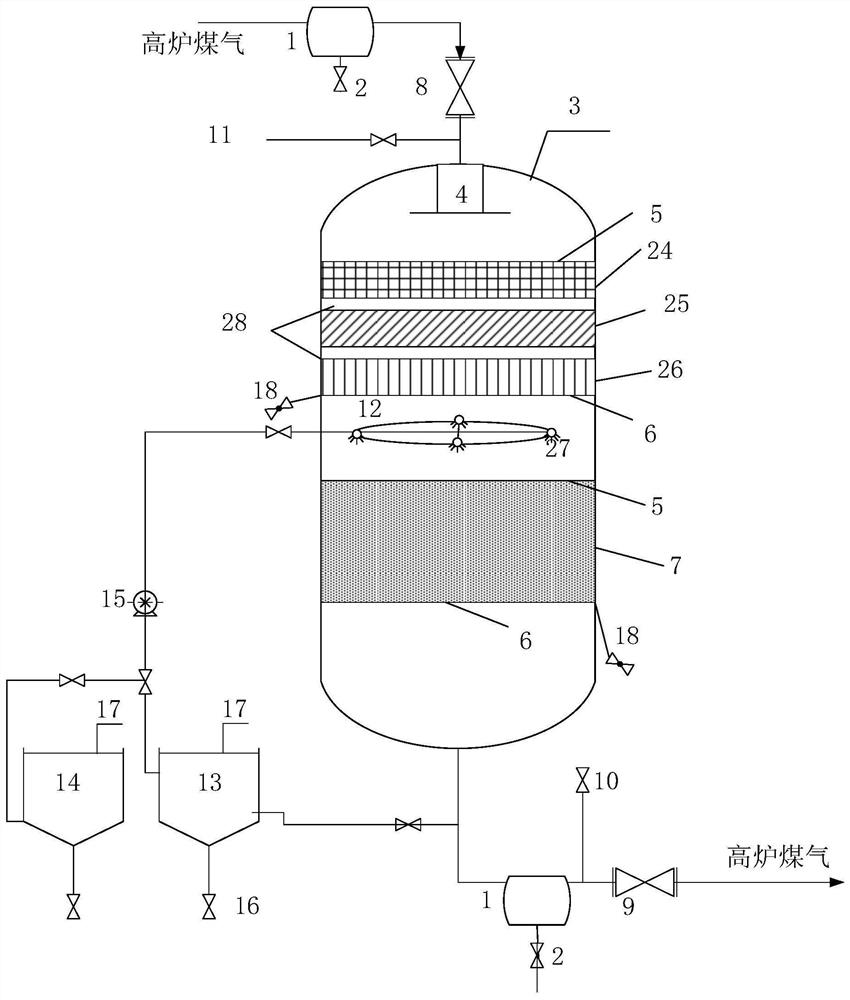

[0158] (1) Blast furnace gas organic sulfur conversion device, such as image 3 As shown, the conversion device includes: a collector package 1, a guide valve 2, a reactor 3, a spray regeneration system; reactor 3 (uploading) includes a gas distributor 4, an upper grid assembly 5, a lower layer? The gate assembly 6, the inlet shutoff valve 8, the outlet shutoff valve 9, the purge line inlet 10, the purge line outlet 11, the catalyst discharge opening 18, the dust filter bed 24, the degrading bed 25, the deoxidizer bed 26 , Organic sulfur conversion catalyst bed 7, alumina porcelain ball 28, reactor adopted as follows. The spray regeneration system includes a spray regeneration line 12, four nozzles 27, a cleaning liquid storage tank 13, a regenerative liquid storage tank 14, a pump 15, a bottom valve 16, and a tap water line 17.

[0159] The spray regeneration system includes a regenerative liquid storage tank 14 mounted outside the reactor 3, a cleaning liquid storage tank 13, a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com