Activated carbon fiber for treating oily wastewater as well as regeneration method and device of activated carbon fiber

A technology of activated carbon fiber and wastewater, which is applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. The effect of secondary pollution, strong resistance to load changes, and easy industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

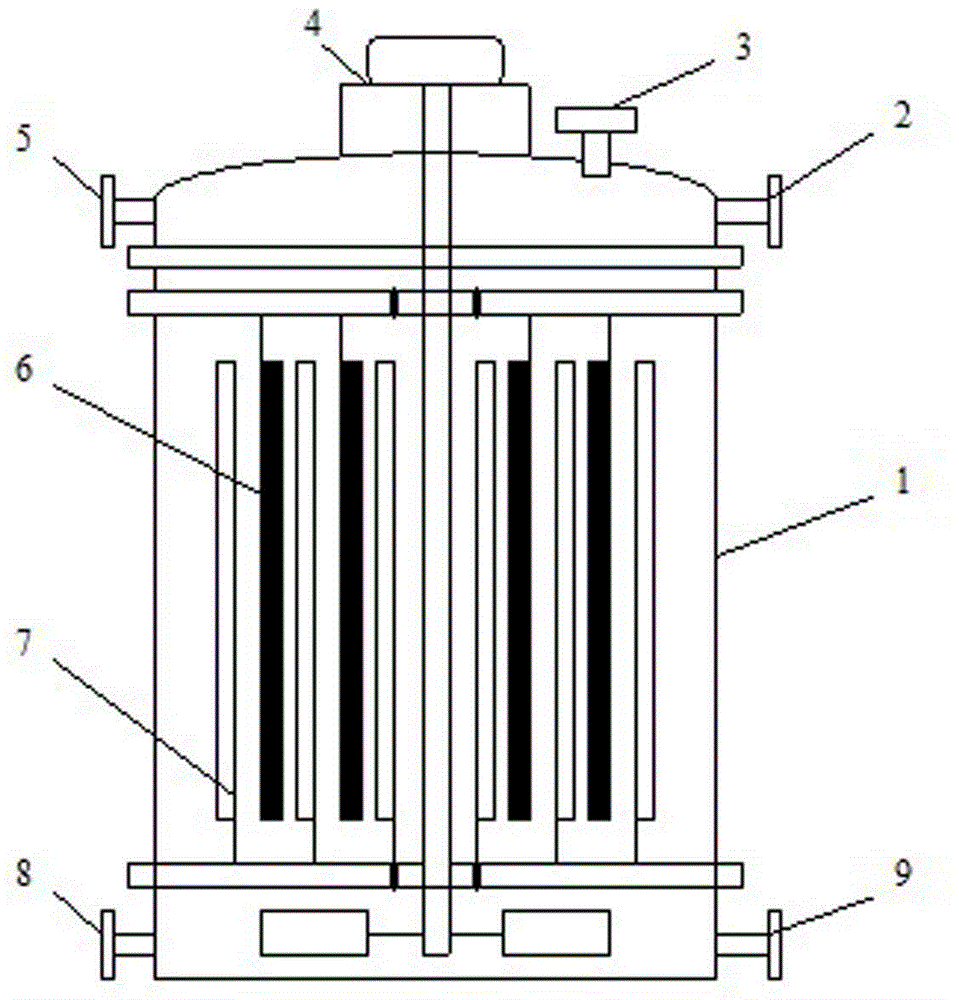

[0057] An activated carbon fiber treatment of oily wastewater and its regeneration device, including a reactor 1, a nozzle installed on the reactor 1, and an electric mixer 4 (the mixer is located at the bottom of the reactor, not shown in the figure), in the reactor 1 Multiple sets of alternately arranged anodes 6 and cathodes 7 are provided, and the anodes 6 and cathodes 7 are respectively introduced into the reactor through wires or plates to connect to an external DC power supply.

Embodiment 2

[0059] On the basis of the above-mentioned embodiment 1, the anode is an activated carbon fiber felt wrapped on a titanium-based metal oxide as the anode, and the cathode is a pure titanium metal as the cathode. And both the titanium-based metal oxide and the pure titanium metal have a network structure.

Embodiment 3

[0061] On the basis of the above-mentioned Example 1 or Example 2, the nozzles arranged on the reactor include: the auxiliary regeneration liquid inlet 2 at the top of the reactor 1, the exhaust port 3, the waste water outlet 5 and the outlet at the reactor 1 Auxiliary regeneration fluid outlet 8 and waste water inlet 9 at the bottom. Through the setting of specific nozzle positions, the wastewater treatment process adopts low-level inlet and high-level outlet, which is more conducive to its full degradation; the auxiliary regeneration liquid adopts high-level inlet and low-level outlet, which is more convenient for operation and improves work efficiency.

[0062] Next, the method part of the present invention is further described by the following examples

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com