Pre-fabricated building modules and method of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

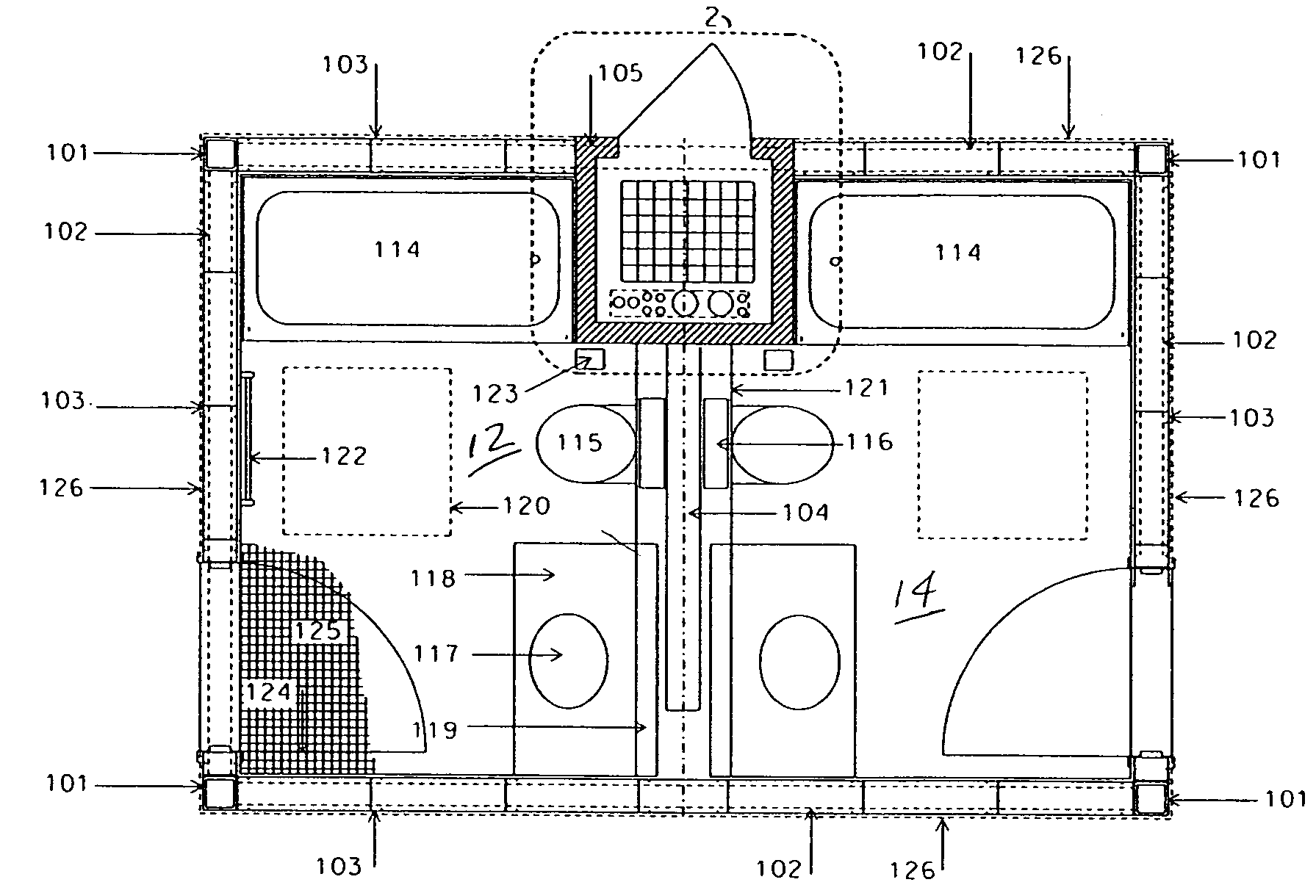

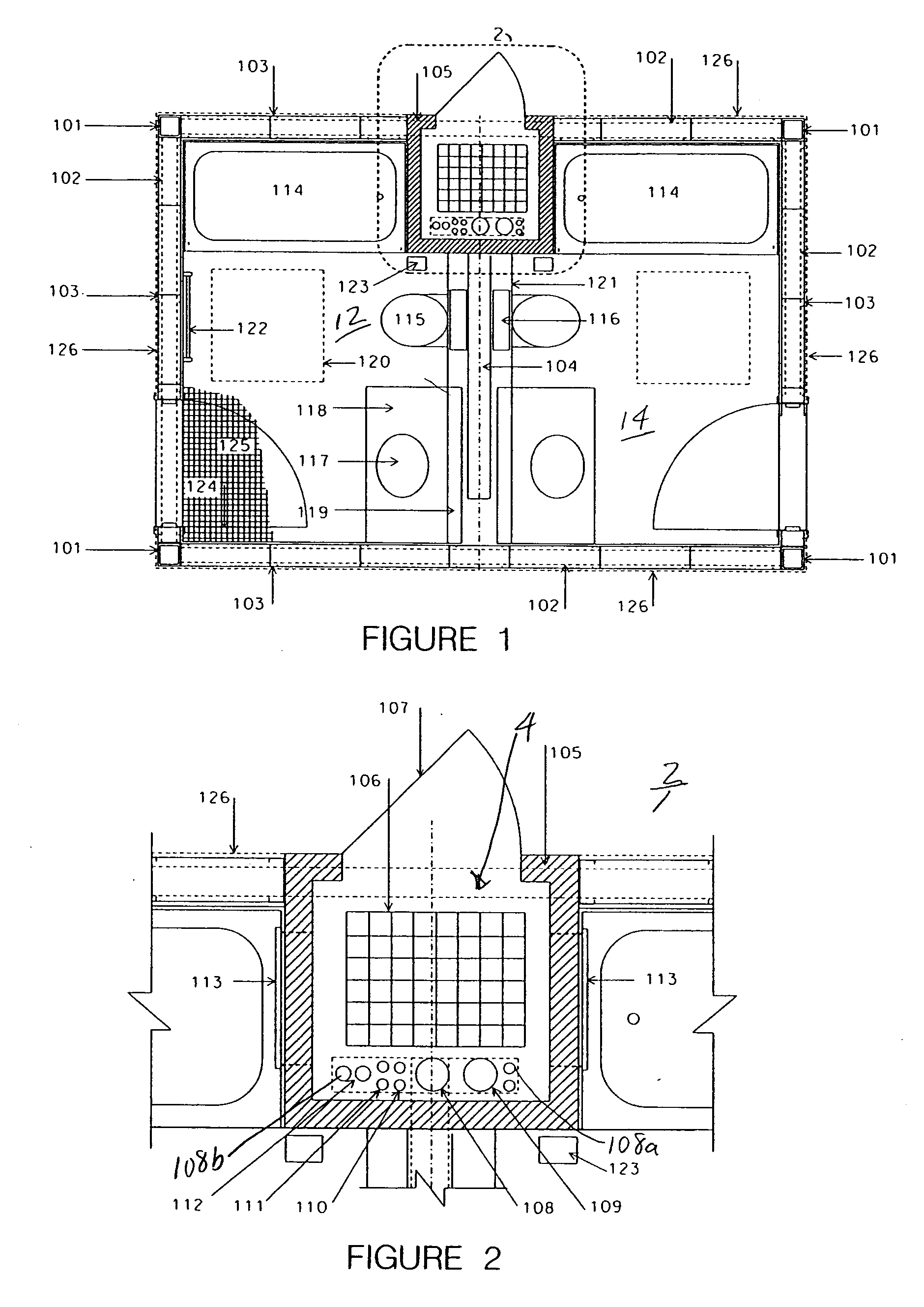

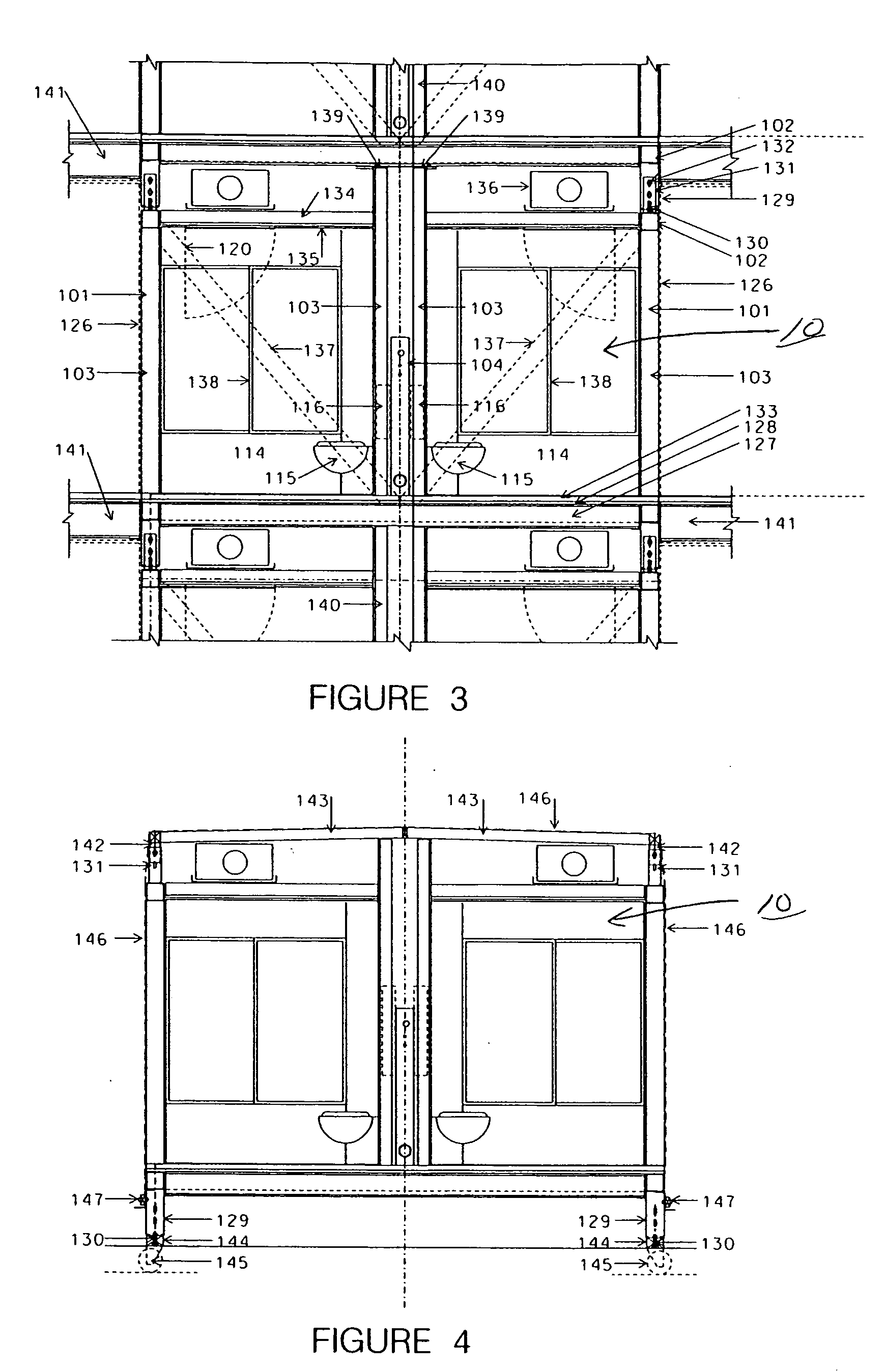

[0044]FIG. 1 illustrates a top view floor plan of a preferred embodiment of the module 100 according to the present invention that includes two bathrooms in a back-to-back, dual bathroom, configuration. The module 10 is also referred to herein as a dual-bath or dual-bathroom module. Bathrooms 12, 14 in dual bathroom module 10 preferably have identical bathroom elements and are shown as mirror images of each other in FIG. 1. As a result, the description of elements in one bathroom also applies to the other bathroom in module 10. A tubular steel frame forms the basic structure of dual bathroom module 10 and includes corner columns 101 and connecting beams 102 at top and bottom. Light gauge metal stud insert panels 103 are attached to the tubular frame to support the perimeter wall finishes. The intermediate wall separating the individual bathrooms 12, 14 contains most of the plumbing installation as a sub-assembly 104.

[0045] The dual bathroom module 10 includes a common vertical shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com