Online monitoring method and system for boiler energy efficiency

A boiler and energy efficiency technology, applied in the field of boiler energy efficiency online monitoring method and system, can solve the problems of not real-time data, boiler operation status evaluation and diagnosis, improve boiler operation energy efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

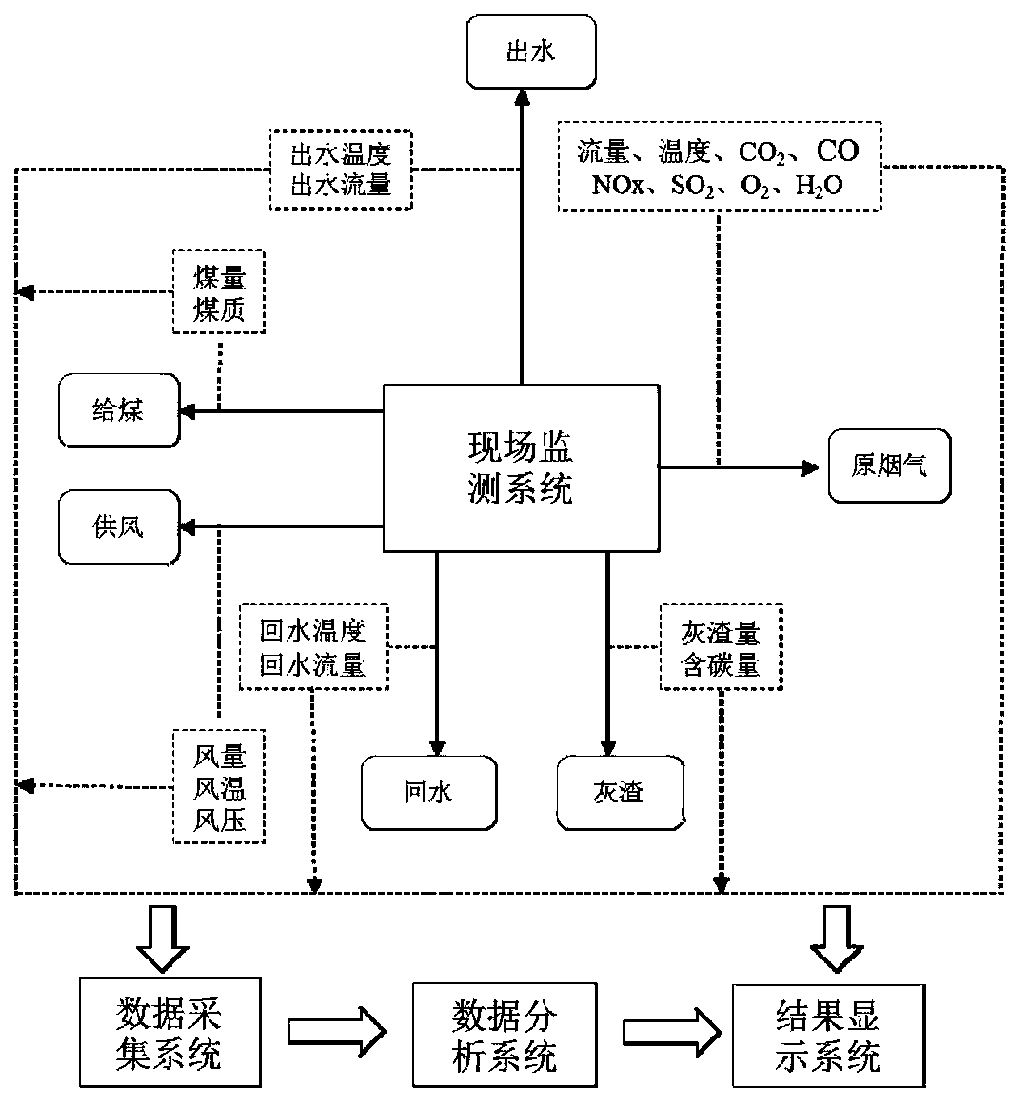

[0046] To make the above-mentioned purposes, features and advantages of the present invention more obvious and understandable, below in conjunction with the attached Figure 1 ~ Figure 2 The present invention will be further described in detail with specific embodiments.

[0047]The boiler energy efficiency online monitoring system adopted in this embodiment includes an on-site monitoring system, a data acquisition system, a data analysis system and a result display system; wherein,

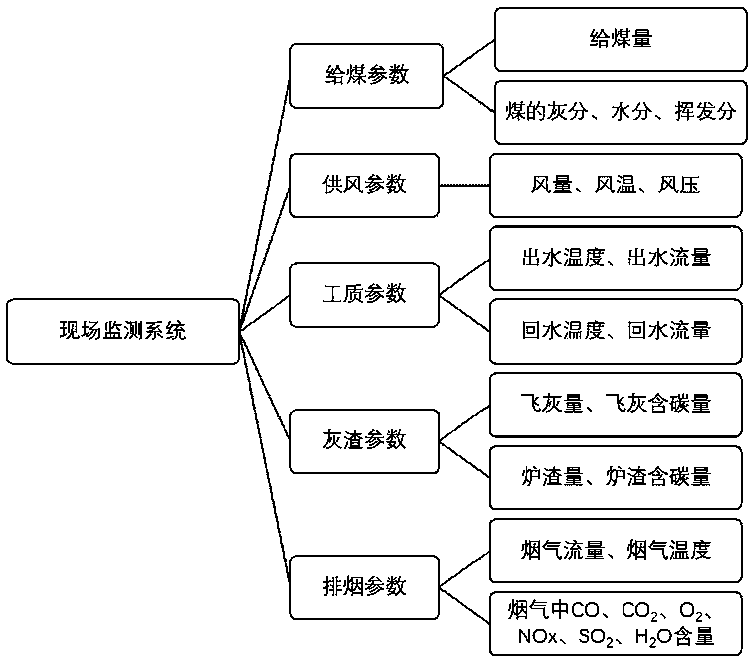

[0048] The on-site monitoring system uses various online monitoring instruments and instruments to monitor coal quality parameters, air supply parameters, working fluid parameters, ash parameters, and smoke exhaust parameters that affect the energy efficiency of boiler operation. The on-site monitoring system in this embodiment includes various online monitoring instruments and instruments, such as: belt weighing machine, coal quality online analysis device, thermal gas mass flowmeter, pressure s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com