Optimal scheduling method for single-stage pump station

A technology for optimizing scheduling and scheduling methods, applied in pump control, liquid variable capacity machinery, machines/engines, etc., can solve problems such as power loss, large amount of discarded water, and planning and design cannot predict the actual timing state, and achieve less energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

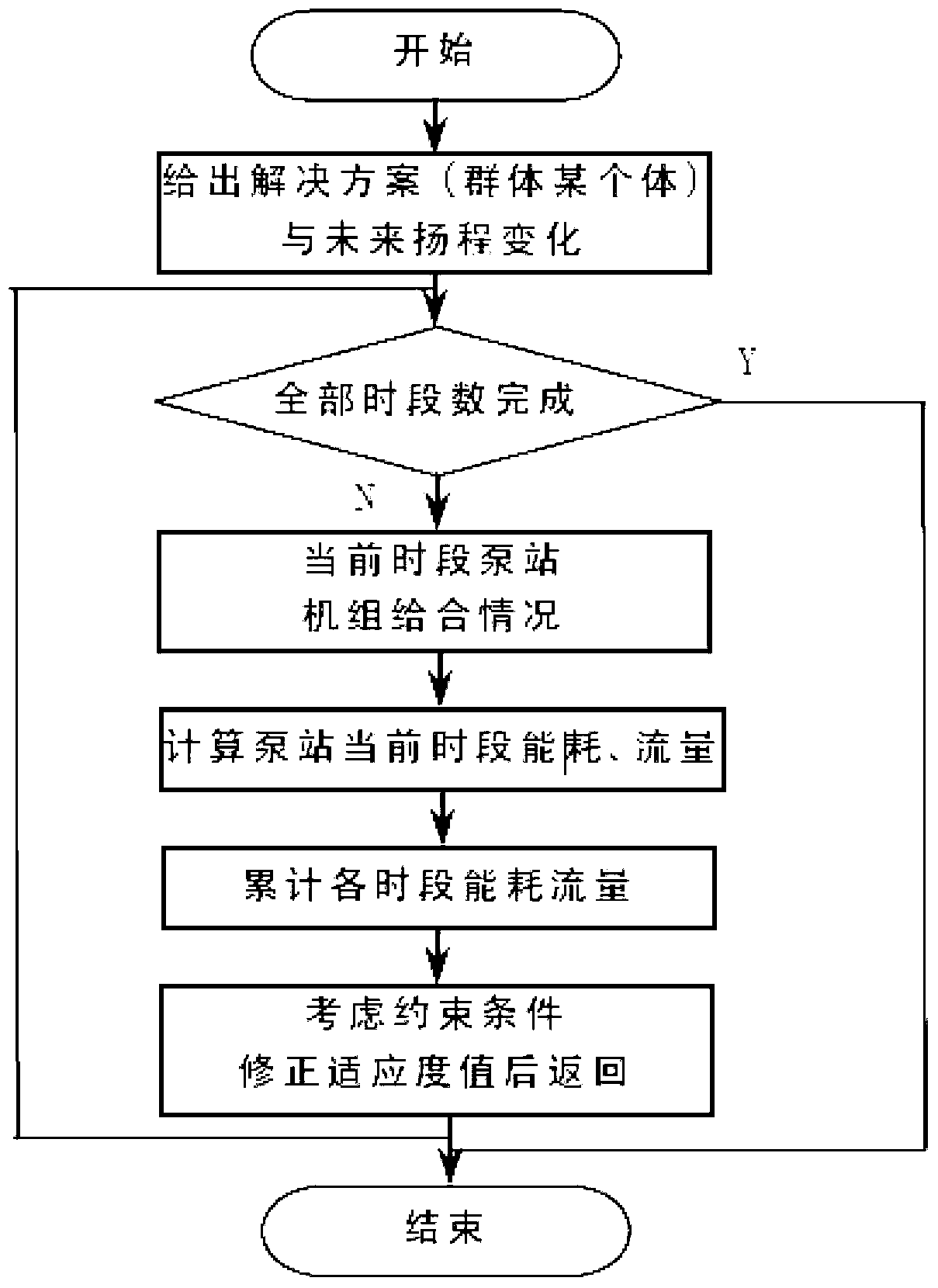

Method used

Image

Examples

Embodiment approach

[0037] The benefit and energy consumption of the pumping station are not only related to the pump, but also related to the efficiency of the motor, the substation, and the regional environment. The operation scheduling of the pumping station is not to pursue the best operating state of a certain equipment, but to optimize the overall coordinated operating state. Target.

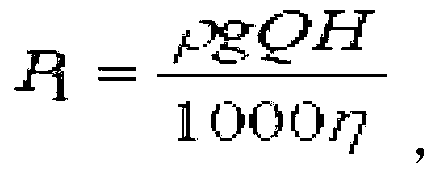

[0038] 1. Pump energy consumption calculation

[0039] When only considering the energy consumption required by the main water pump of the pumping station, without considering the power consumption required by auxiliary equipment, electrical equipment, station substation, etc., the required input power of the main water pump can be described as:

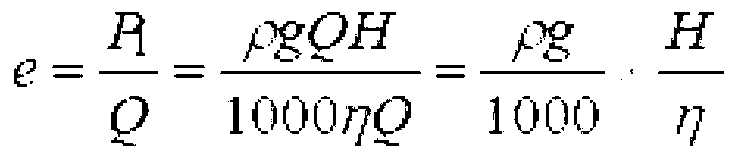

[0040] In a certain period of time, the energy consumption per unit water volume of the pumping station can be described as:

[0041] e = P 1 Q = ρgQH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com