TBM operation parameter optimization method based on optimal tunneling speed and cutter consumption

A technology of excavation speed and operating parameters, applied in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of no TBM optimization, insufficient attention and utilization of rock slag information, and little consideration of TBM, etc. Comprehensive, high-precision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Just as the deficiencies in the existing technology introduced in the background technology, in order to solve the above technical problems, this disclosure proposes a method for optimizing the main operating parameters of TBM based on the optimal driving speed and tool consumption. open for further elaboration.

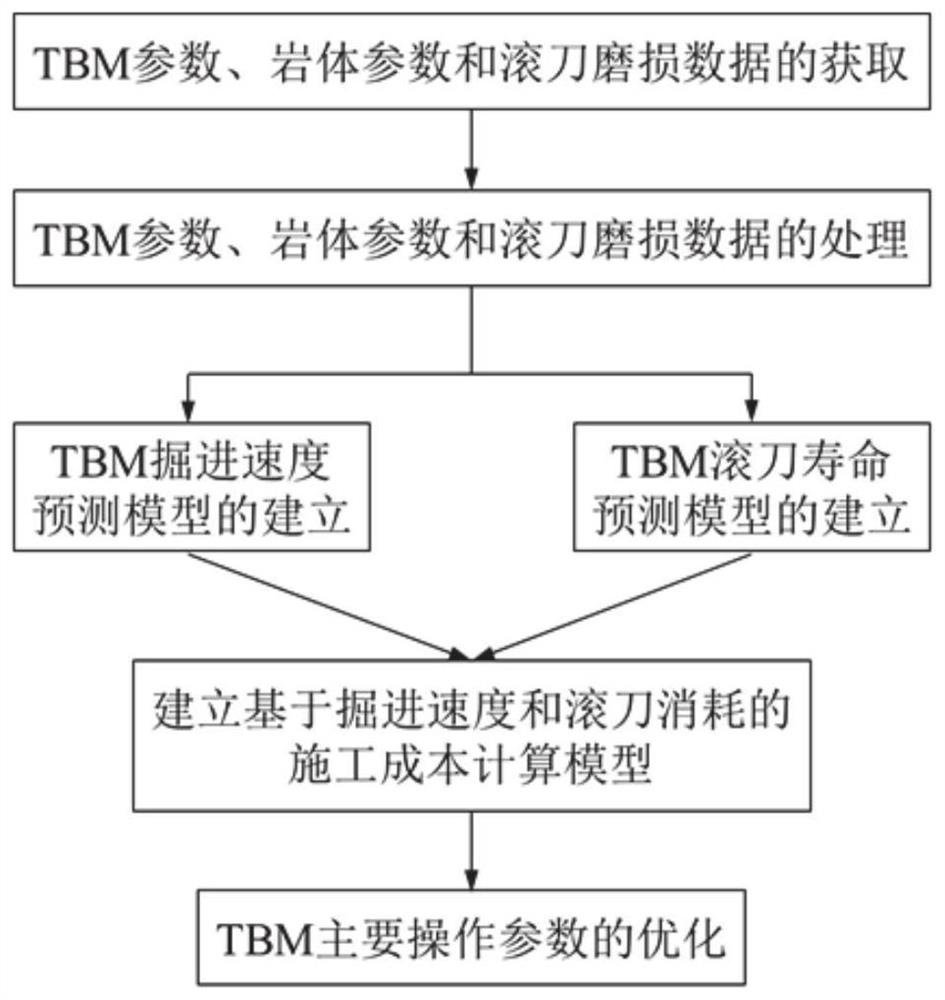

[0059] Such as figure 1 As shown, Embodiment 1 of the present disclosure provides a method for optimizing the main operating parameters of TBM based on the optimal driving speed and tool consumption, including the following steps:

[0060] Obtain rock mass parameter data;

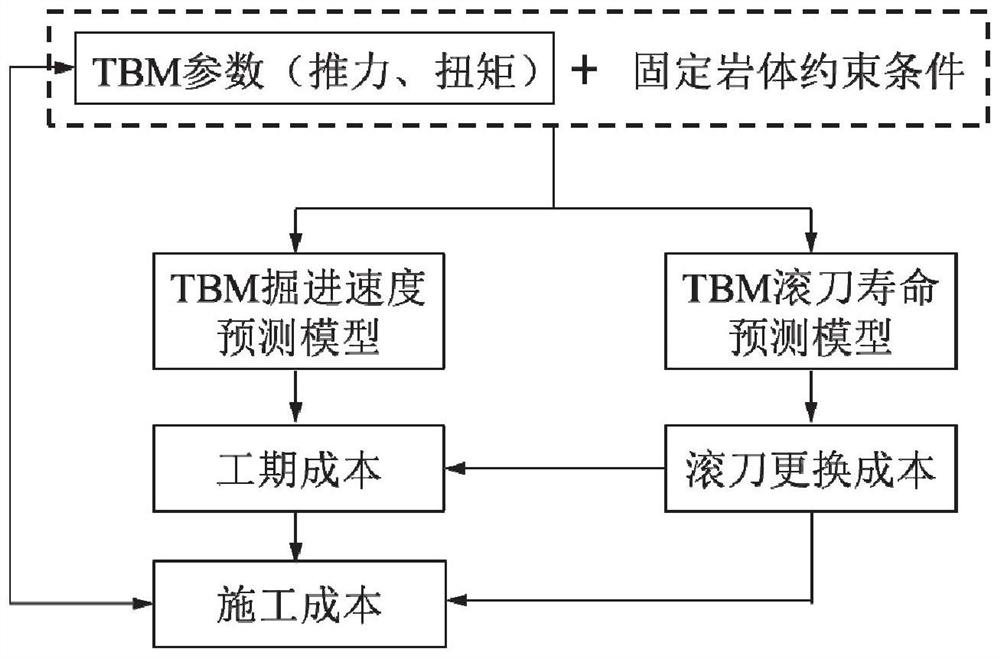

[0061] Using the obtained rock mass parameter data as the input of the preset construction cost calculation model, the cutterhead thrust and cutterhead torque when the construction cost is minimized are obtained through interpolation fitting;

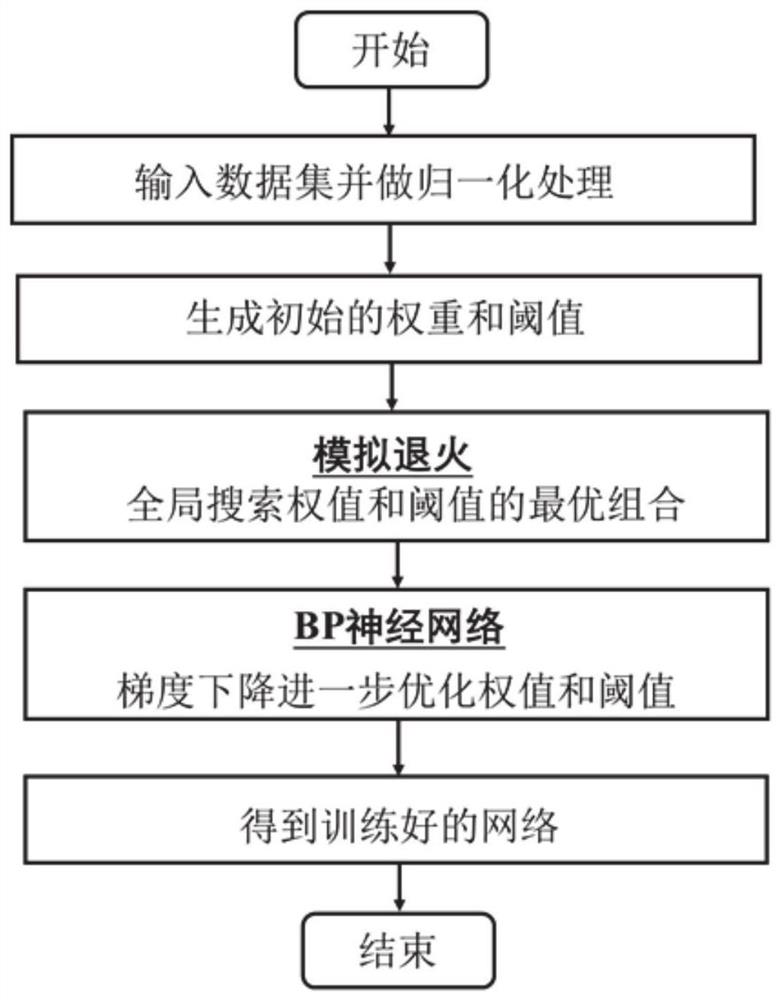

[0062] Among them, the preset construction cost calculation model includes a TBM tunneling speed prediction model and a TBM hob life prediction mo...

Embodiment 2

[0130] Embodiment 2 of the present disclosure provides a TBM operating parameter optimization system based on optimal tunneling speed and tool consumption, including:

[0131] The data acquisition module is configured to: acquire rock mass parameter data;

[0132] The parameter optimization module is configured to: use the obtained rock mass parameter data as the input of the preset construction cost calculation model, and obtain the cutterhead thrust and cutterhead torque when the construction cost is the smallest through interpolation fitting;

[0133] Among them, the preset construction cost calculation model includes a TBM tunneling speed prediction model and a TBM hob life prediction model.

[0134] The working method of the system is the same as the TBM operating parameter optimization method based on the optimal driving speed and tool consumption provided in Embodiment 1, and will not be repeated here.

Embodiment 3

[0136] The third aspect of the present disclosure provides a computer-readable storage medium on which a program is stored, and when the program is executed by a processor, the optimal TBM operating parameters based on the tunneling speed and tool consumption as described in the first aspect of the present disclosure are realized. Steps in the optimization method, the steps being:

[0137] Obtain rock mass parameter data;

[0138] Using the obtained rock mass parameter data as the input of the preset construction cost calculation model, the cutterhead thrust and cutterhead torque when the construction cost is minimized are obtained through interpolation fitting;

[0139] Among them, the preset construction cost calculation model includes a TBM tunneling speed prediction model and a TBM hob life prediction model.

[0140] The detailed steps are the same as the TBM operation parameter optimization method based on the optimal tunneling speed and tool consumption provided in Embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com