Device and method for treating sewage with low ratio of carbon to nitrogen

A technology with low carbon-to-nitrogen ratio and sewage, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as high cost and unsatisfactory total nitrogen removal effect, and achieve Achieve water quality requirements, good complementarity and operational flexibility, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

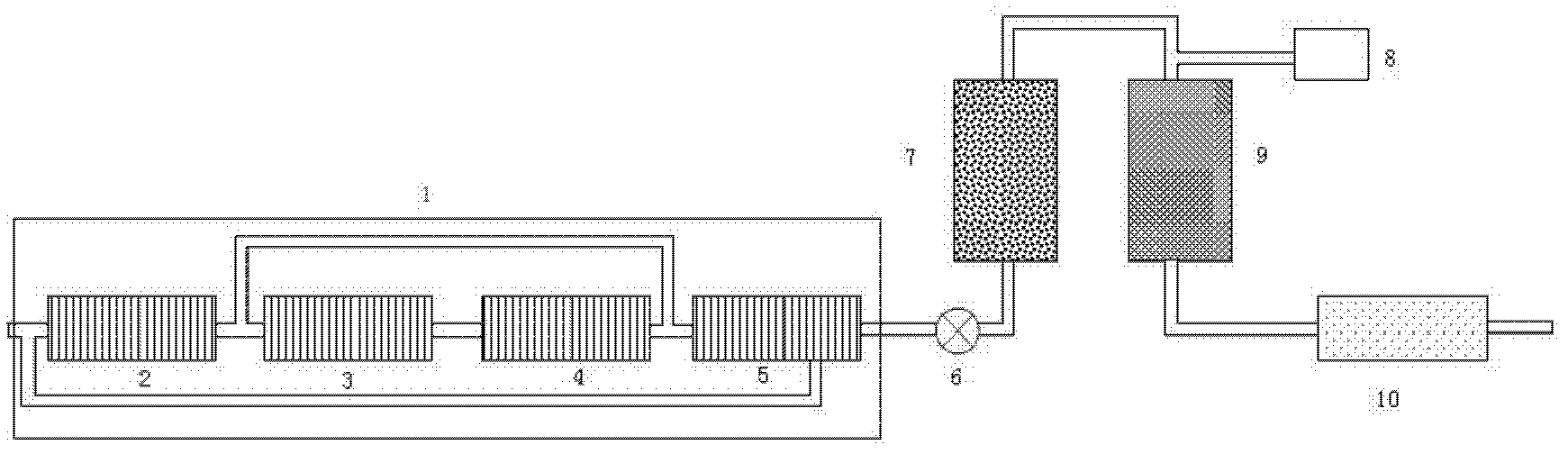

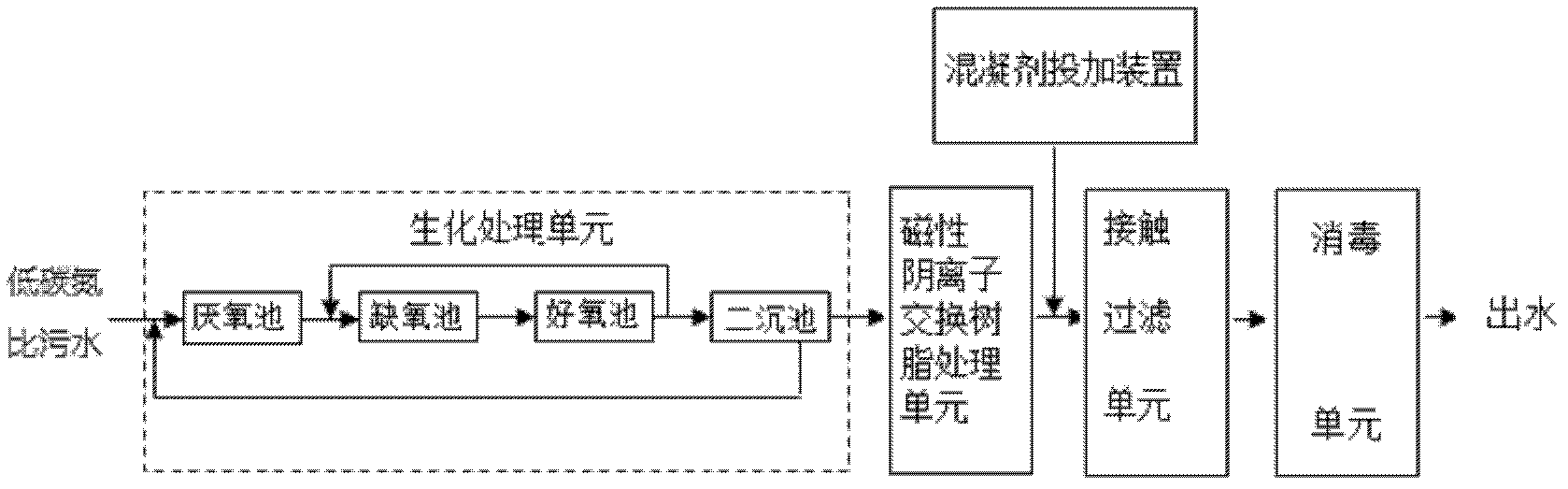

[0028] The device for treating sewage with low carbon-to-nitrogen ratio, the schematic diagram of its structure is as follows figure 1 As shown, the biochemical treatment unit 1, lift pump 6, magnetic anion exchange resin treatment unit 7, contact filter unit 9, and disinfection unit 10 are sequentially connected in series through pipelines. The biochemical treatment unit consists of anaerobic tank 2, anoxic tank 3, The aerobic tank 4 and the secondary settling tank 5 are connected in series through pipelines. The end of the aerobic tank is provided with an internal return pipeline that returns to the anoxic tank, and the secondary settling tank is provided with an external return pipeline that returns to the anaerobic tank. The outlet of the secondary settling tank is for biochemical treatment The outlet of the unit, the magnetic anion exchange resin processing unit 7 includes magnetic anion exchange resin. It also includes a coagulant dosing device 8, which is connected to t...

Embodiment 2

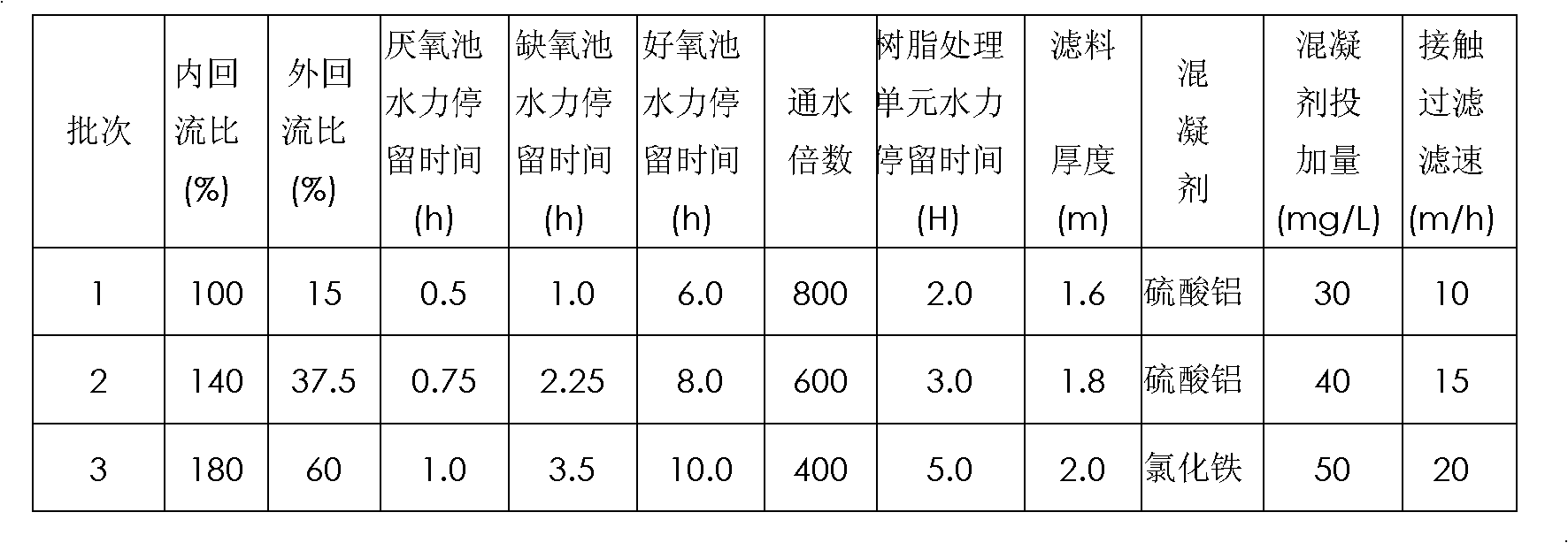

[0030] Treatment of three batches of low carbon nitrogen ratio sewage:

[0031] (1) Biochemical treatment: Sewage with a low carbon-to-nitrogen ratio flows into the biochemical treatment unit, and enters the intermediate pipeline after being treated in the anaerobic tank, anoxic tank, aerobic tank, and secondary sedimentation tank; due to the relatively low carbon source content, the biochemical treatment unit The operating parameters adopt lower internal and external reflux ratios, which are 100% to 180% and 15% to 60% respectively, and the hydraulic retention times of anaerobic pools, anoxic pools, and aerobic pools are respectively set to 0.5 to 1h and 1.0 ~3.5, 6~10h;

[0032] (2) Ion exchange: The water in the middle pipeline enters the magnetic anion exchange resin treatment unit after being pressurized by the lift pump. The rate is controlled at about 150%; the effluent from the magnetic anion exchange resin treatment unit flows into the water inlet of the contact filt...

Embodiment 3

[0039] Regular A 2 O process + coagulation-sedimentation-filtration process to treat sewage with low carbon-to-nitrogen ratio:

[0040] (1) Biochemical treatment: Sewage with a low carbon-to-nitrogen ratio flows into the biochemical treatment unit, and enters the intermediate pipeline after being treated in the anaerobic tank, anoxic tank, aerobic tank, and secondary sedimentation tank; the operating parameters of the biochemical treatment unit are: internal and external The reflux ratio is 300% and 100% respectively, and the hydraulic retention time of the anaerobic pool, anoxic pool, and aerobic pool are set to 1.5h, 3.0, and 5.0h respectively;

[0041](2) Coagulation-sedimentation-filtration advanced treatment: the water in the middle pipeline is lifted into the coagulation unit. The coagulant is polyaluminum chloride, the dosage is 60mg / L, and it is mixed with a pipeline mixer; the flocculation tank is a folding plate flocculation tank, and the residence time is 15 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| inhomogeneity coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com