Seamless steel tube production process information tracking method

A seamless steel pipe and production process technology, applied in the field of metallurgy, can solve problems such as only tracking by batch, and achieve the effect of improving product quality and optimizing operating parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

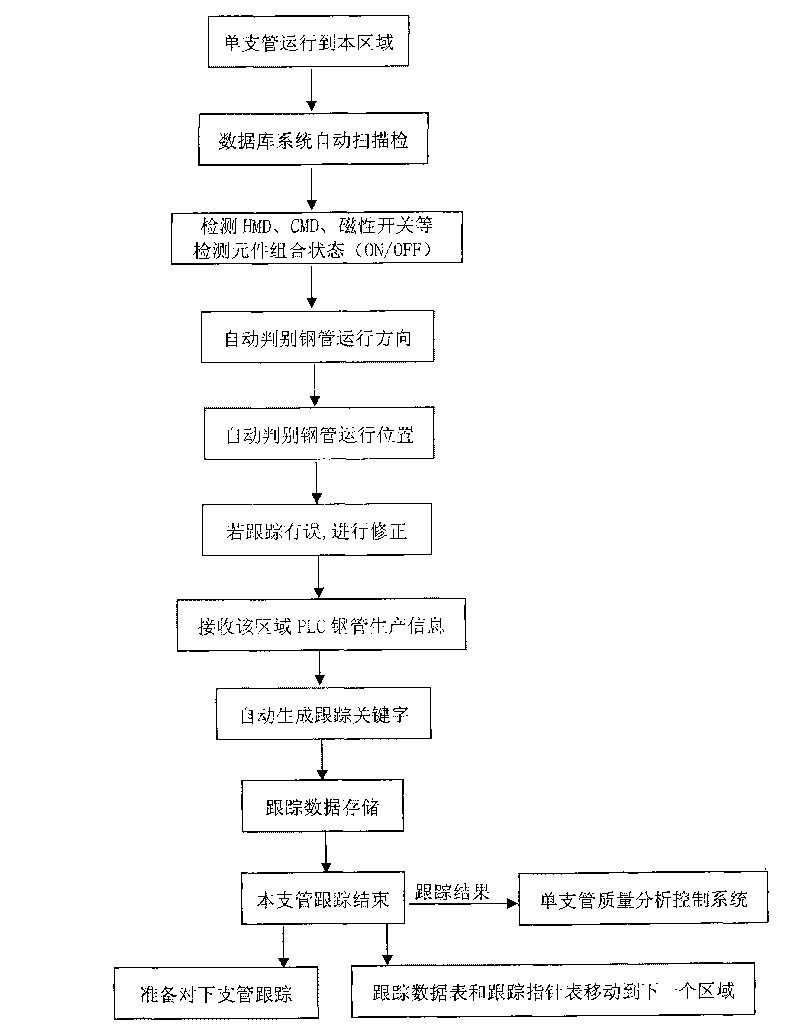

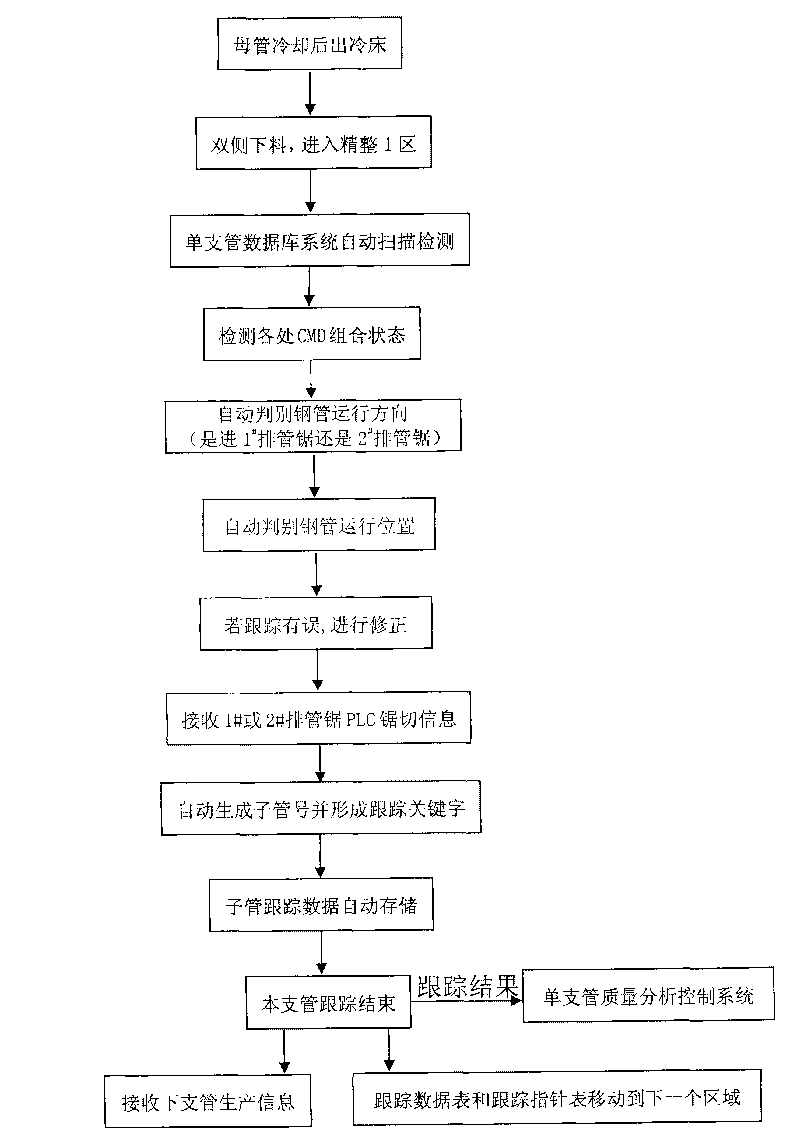

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings.

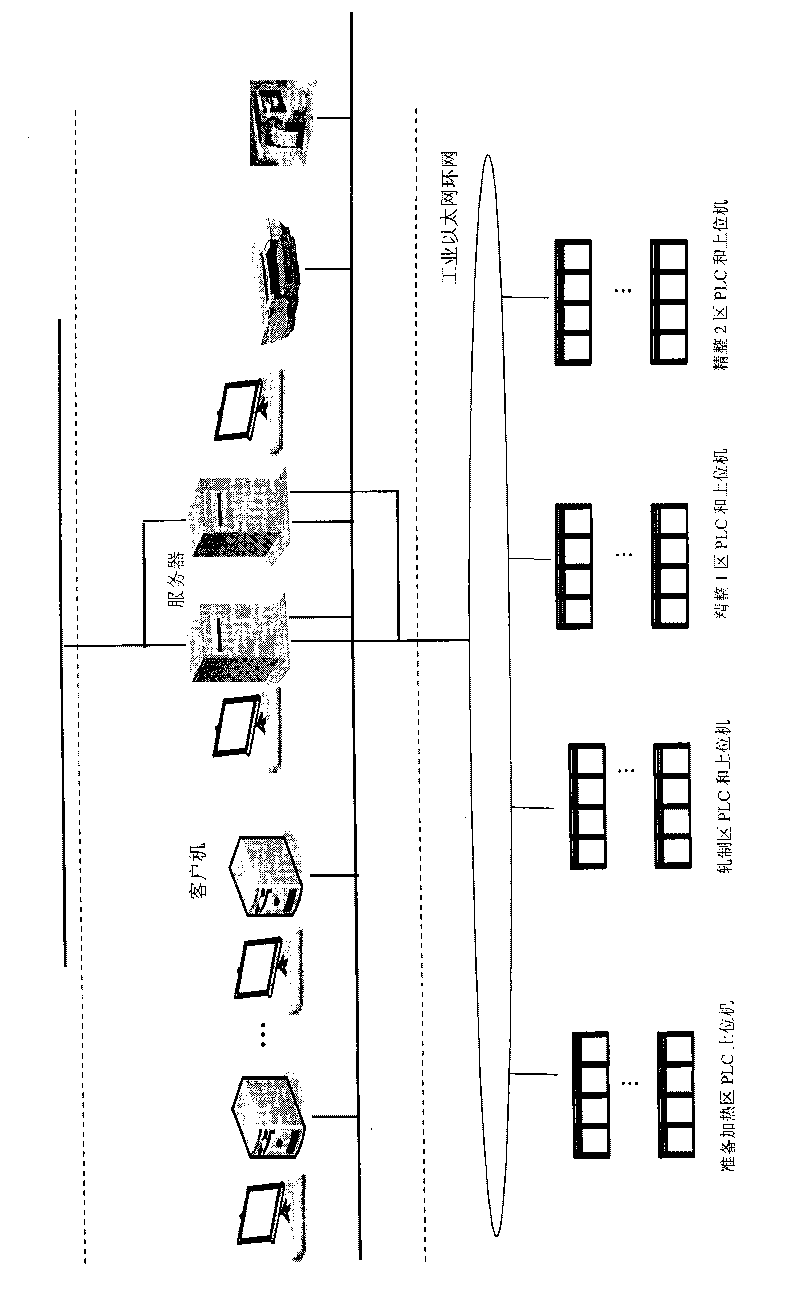

[0027] Such as figure 1 Shown, the hardware configuration structure schematic diagram of the present invention

[0028] The invention relates to a seamless steel pipe production process information tracking method, and the hardware part is composed of a client computer and a server. The server ensures data integrity through disk array technology. The working mode of the server is one worker and one standby. System software development can be performed offline on a spare computer. The client computers are installed in each operating room and computer room to realize the human-computer interaction function. The system network connection adopts star connection. Each server is equipped with an Ethernet card for network communication.

[0029] Such as figure 1 Shown, a kind of seamless steel pipe production process information tracking method of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com