Fluid mixing method and device thereof

A fluid mixing and fluid technology, applied in mixers, chemical instruments and methods, shaking/oscillating/vibrating mixers, etc., can solve problems such as insufficient working range, achieve short mixing time, low energy consumption, and accelerated chemical reactions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

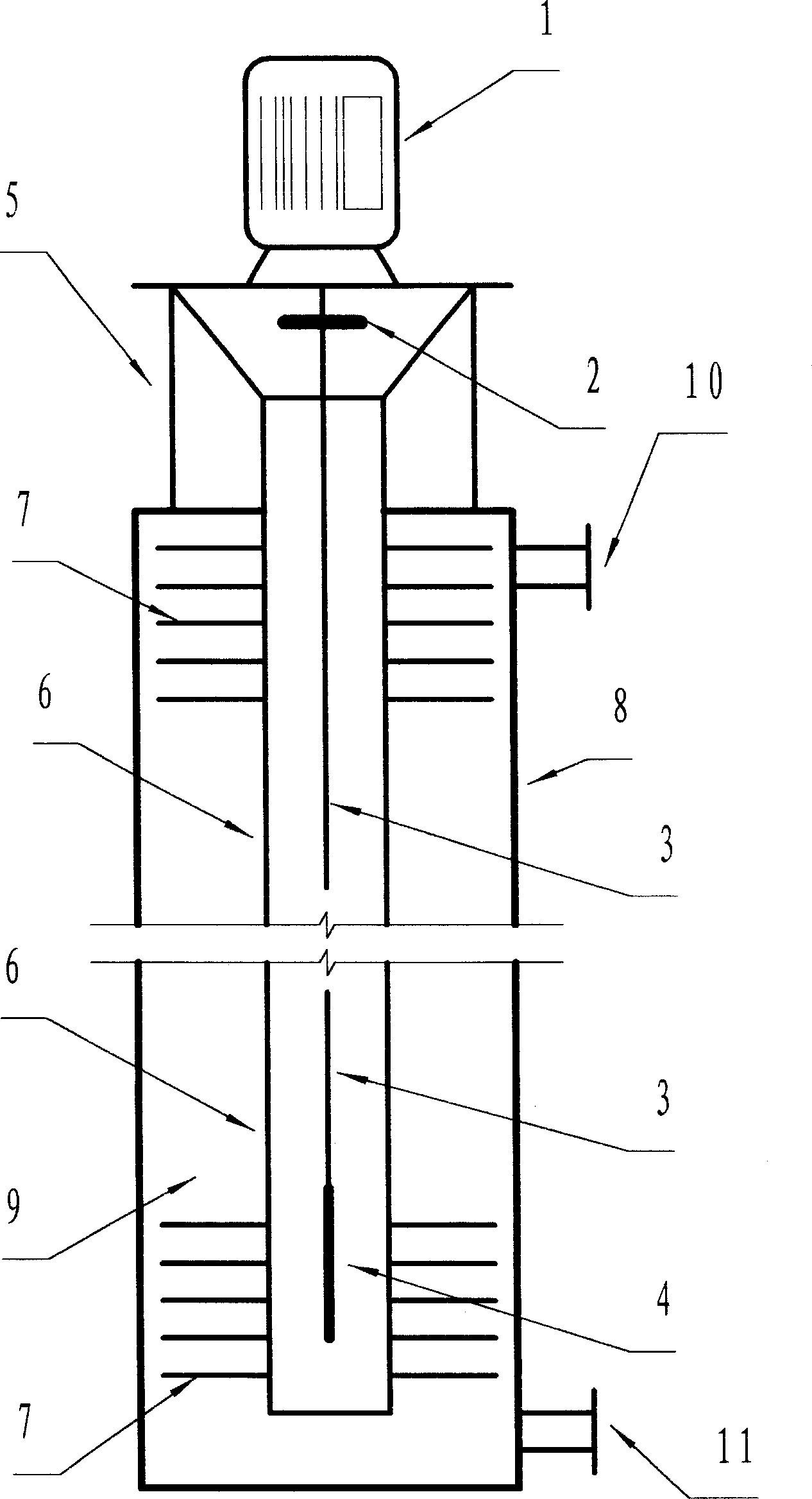

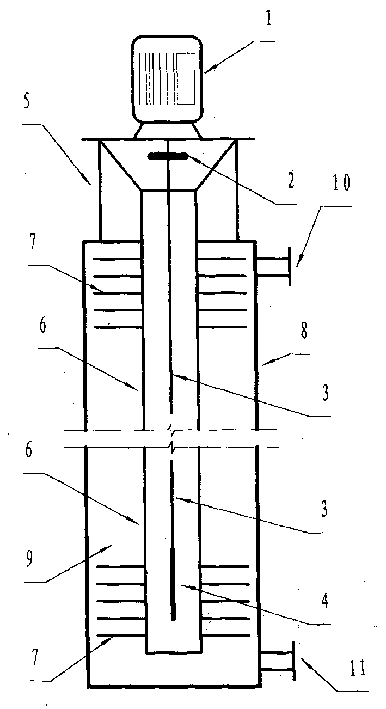

[0035] The essence of the fluid mixing method of the present invention is to transform high-speed rotational stirring into rigid body high-frequency oscillation. The preferred method is to install a number of elastic vibrating fins on the outer wall of the rigid body, so as to transmit the high-frequency vibration to all the layers around the rigid body, where there is fluid, the vibrating fins are installed. Another preferred method is to make the fluid mixing device move in the fluid container, as long as an opening coincident with the moving track of the rigid body is provided on the upper cover of the container, manual or mechanical movement can be realized. This method eliminates the need to install oscillating fins and move the device to where the fluid needs enhanced mixing.

[0036] Such as figure 1 As shown, a fluid mixing device implementing the above method is composed of a vibrator and an oscillator, wherein the vibrator is composed of a prime mover (1) and a perc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com