Control system and process for wastewater treatment

A waste water treatment and fluid technology, applied in water treatment parameter control, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of large system, time delay, not receiving mixing time and mixing energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT

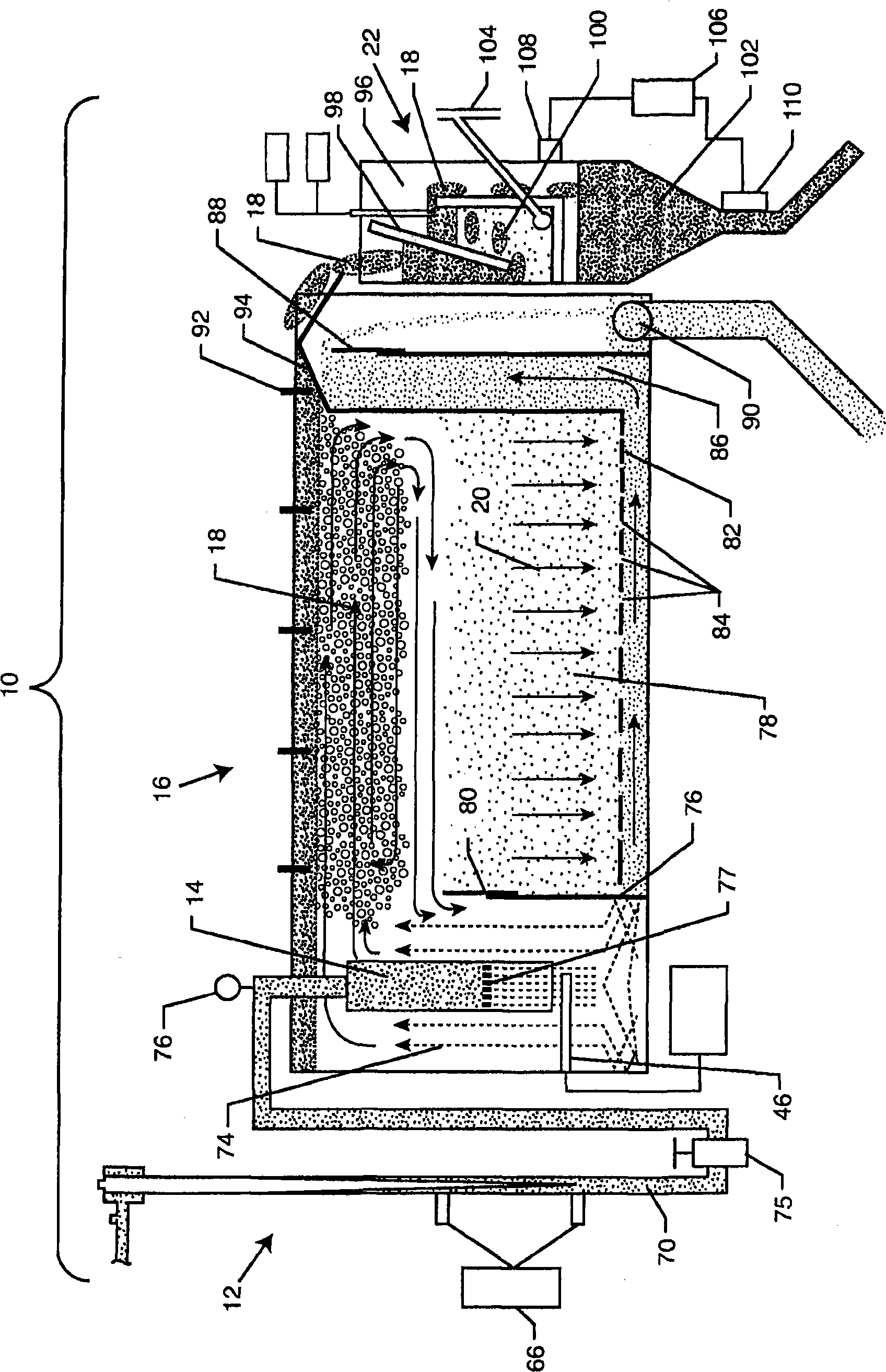

[0030] [Paragraph 29] This disclosure of wastewater treatment control systems and methods is generally referred to by reference numeral 10, as shown in the exemplary drawings for purposes of illustration. Turning now to the representative drawings in the specification, figure 1 A wastewater treatment control system 10 is shown having a mixer 12 fluidly coupled to a nucleation chamber 14 disposed within a flotation cell 16 . The mixer 12, which will be described in more detail herein, is specifically designed to mix chemical additives, gases etc. into the contaminated liquid. The gas is entrained in the liquid at a small size to adhere to the solid particles and flocculants. Thereafter, as the liquid passes through the nucleation chamber 14 , the bubble size increases and lifts the float and solid contaminants towards the surface of the flotation cell 16 . Eventually, the floating particles form a sludge or scum 18 whil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com