Variable frequency low speed mixer and method for mixing materials with different stacking densities

A low-speed mixer and bulk density technology, which is applied in the field of plastic processing, can solve problems such as unstable product performance, uneven raw material premixing, and low product yield, so as to avoid uneven mixing of materials and reduce the chance of delamination. The effect of reducing mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

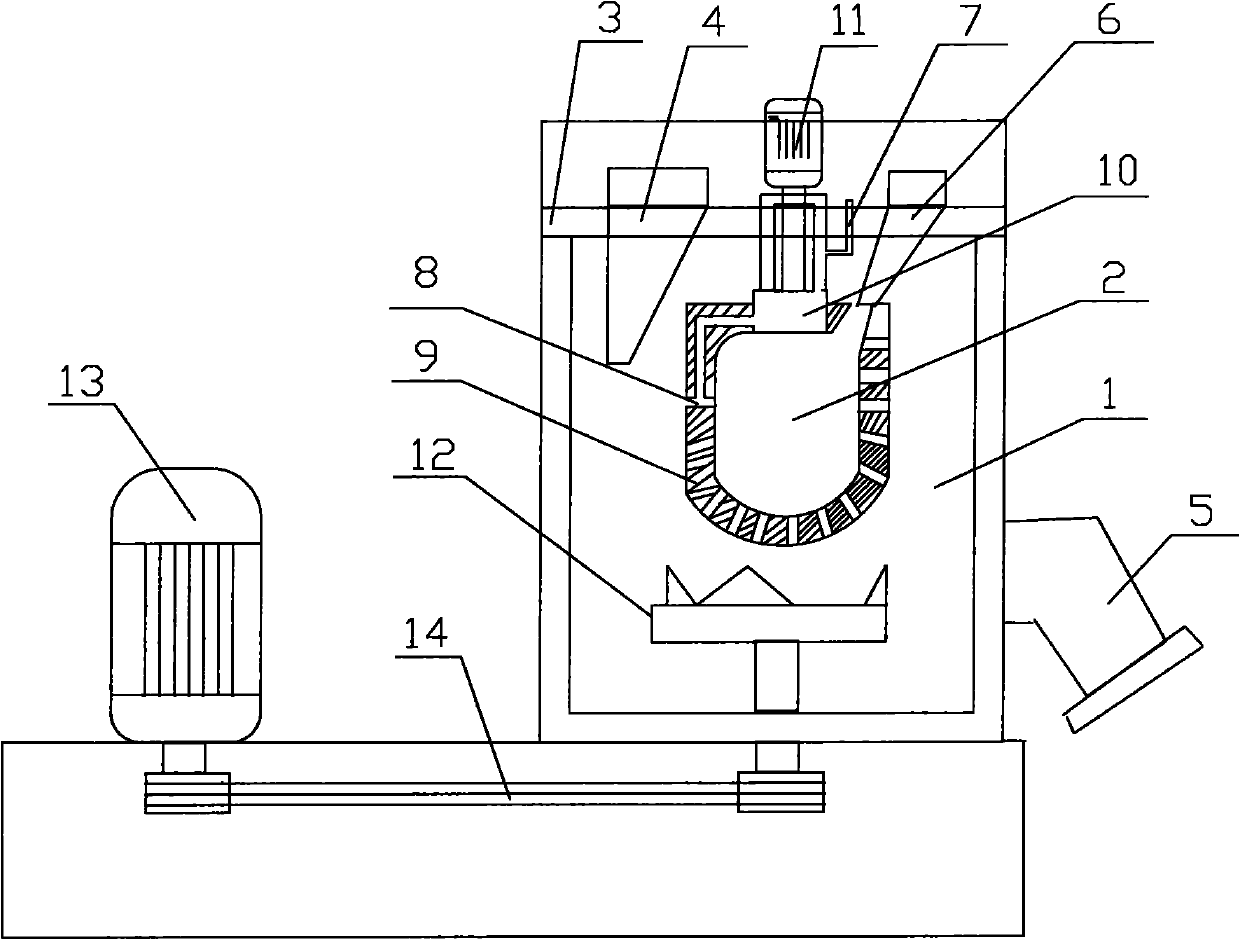

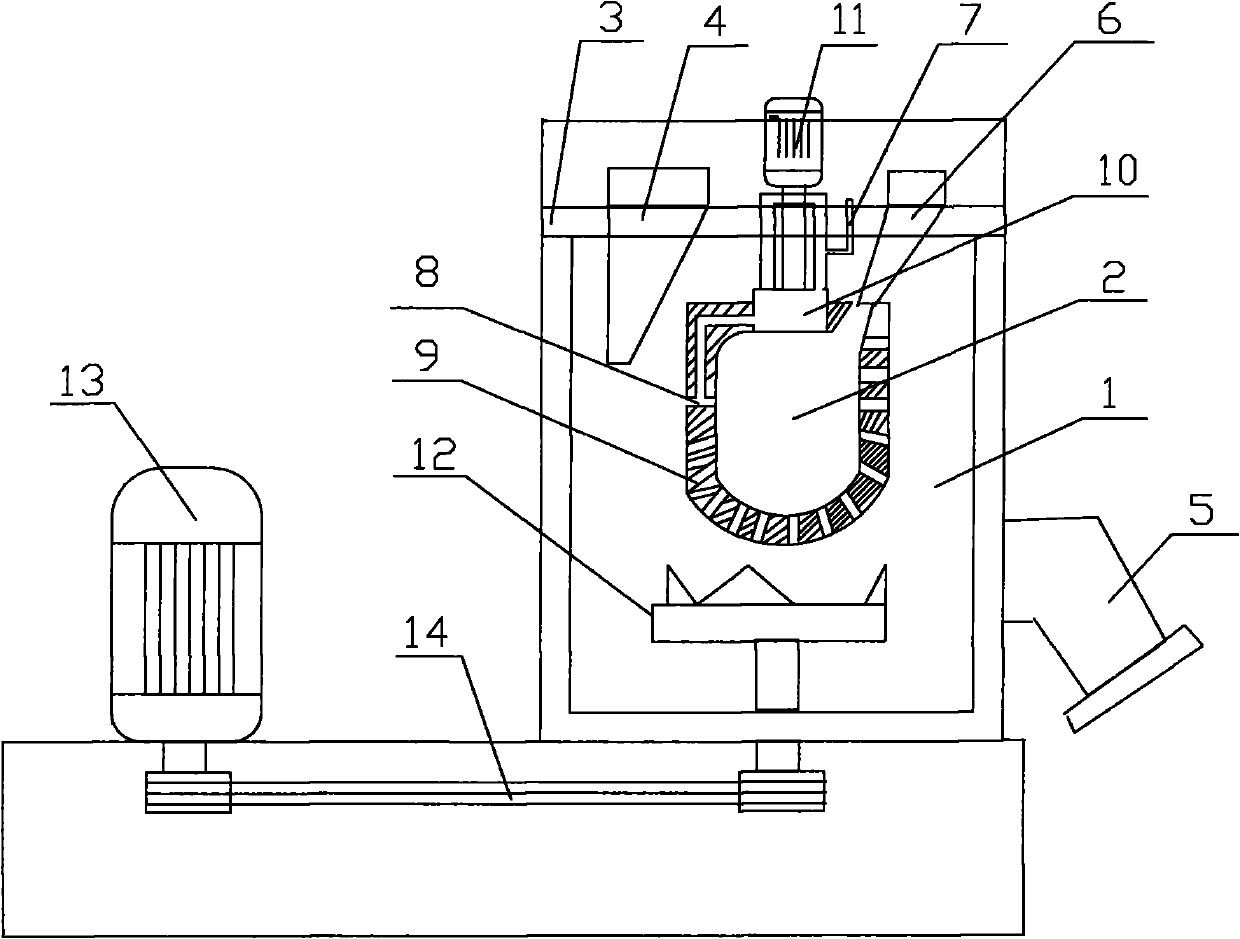

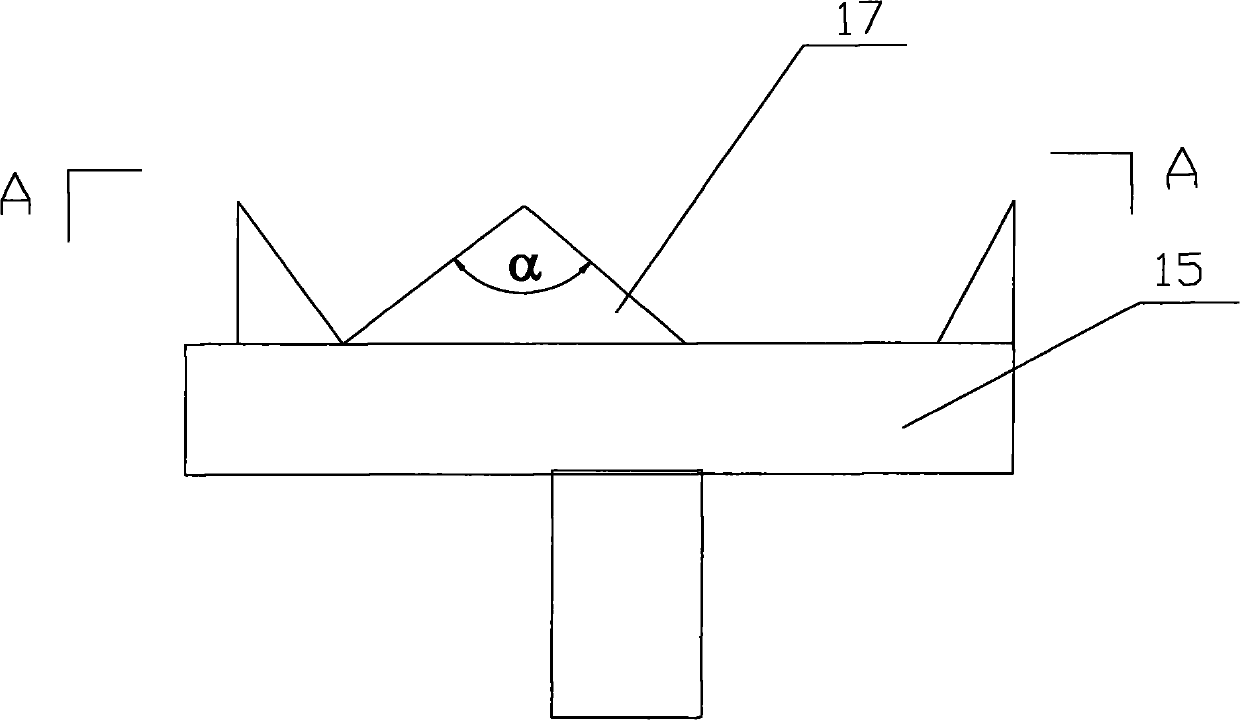

[0027] This embodiment is a frequency conversion low-speed mixer for mixing materials with different bulk densities, its structure is as follows figure 1 As shown, it includes a main mixing chamber 1 and an auxiliary mixing chamber 2, the auxiliary mixing chamber 2 is located inside the main mixing chamber 1, the mixer cover 3 of the main mixing chamber 1 is provided with a pellet feeding port 4, and the bottom of the main mixing chamber 1 There is an impeller mechanism, the top of the auxiliary mixing chamber 2 is provided with a powder feeding port 6 and a liquid feeding port 7, and the wall of the auxiliary mixing chamber 2 is provided with a liquid material outlet 8 and a plurality of powder material outlets 9, The top of the auxiliary mixing chamber 2 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com