Patents

Literature

34results about How to "Reduce the chance of delamination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multielement silane coupling agent-modified phenolic resin base combined disc brake pad and preparation method thereof

ActiveCN105801014AImprove physical propertiesGood chemical propertiesFriction liningCarbon fibersSilanes

The invention provides a multielement silane coupling agent-modified phenolic resin base combined disc brake pad and a preparation method thereof, and relates to the technical field of automobile parts.The brake pad is prepared from, by mass, 4-7% of organosilicone-modified phenolic resin, 2-4% of polyacrylonitrile carbon fibers, 2-4% of aramid pulp, 10-34% of potassium titanate lamellae, 5-18% of steel fibers, 2-6% of glass fibers, 3-10% of natural flake graphite, 3-10% of granulated coke, 0.5-1.5% of silicon dioxide, 25-40% of barite and 2.5-10% of a multielement silane coupling agent.The disc brake pad has the advantages of being good in interfacial compatibility, stable in friction coefficient and product quality, excellent in wear resistance and anti-noise performance and the like; besides, a material modification process and a mixing process are integrated in the preparation method of the disc brake pad, so that production efficiency is high, modification cost is lowered, and the process is simple.

Owner:SHANDONG GOLD PHOENIX

Inner electrode silver paste for inductor and preparation method

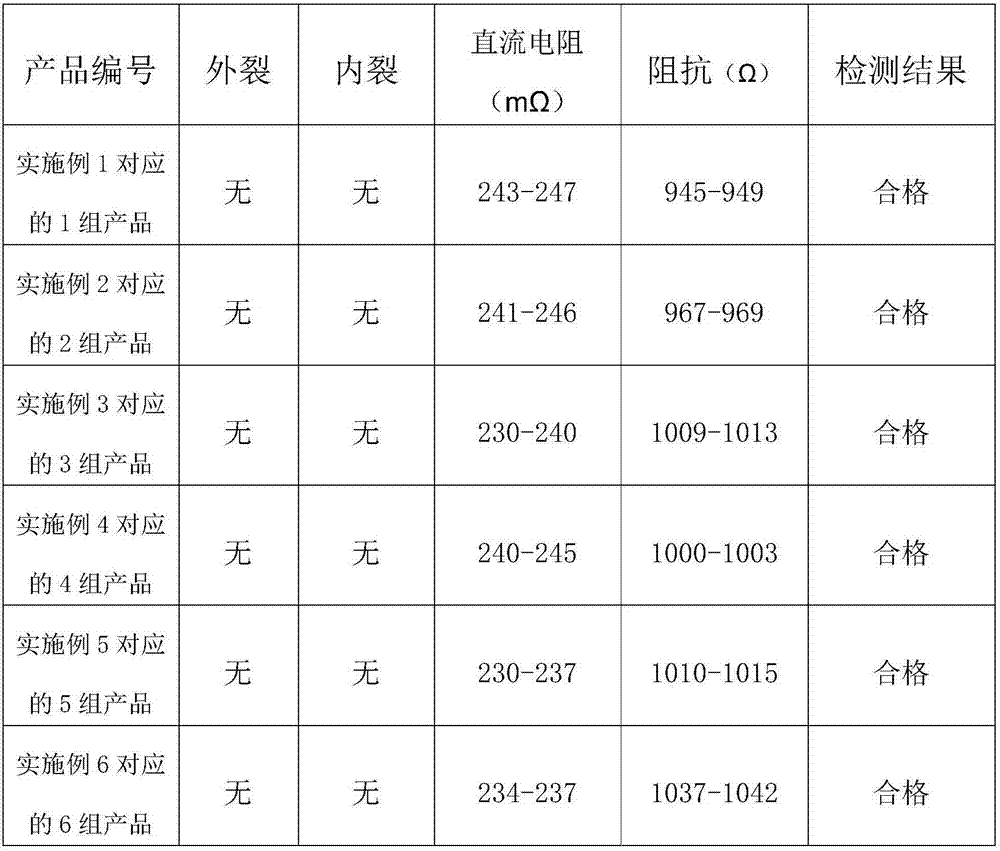

ActiveCN107093489AReduce the chance of delaminationIncrease the organic solid contentTransformers/inductances coils/windings/connectionsNon-conductive material with dispersed conductive materialSolventElectron

The invention relates to the technical field of electronic materials for electronic components, and particularly relates to an inner electrode silver paste for an inductor and a preparation method. The inner electrode silver paste comprises the following components in percentage by weight: 35%-60% of crystal silver powder, 15%-40.5% of silver micro powder, 5%-15% of silver oxide powder, 0.01%-0.5% of glass or an inorganic oxide, 1%-5% of ethyl cellulose, 1%-5% of one or more alcoholic solvents, 1%-10% of one or more ester solvents, 0.5%-5% of rosin, wherein the sum of the weight percentages of the components is 100%. The grain diameter of the crystal silver powder is 1.0-3.0 micrometers, and the grain diameter of the silver micro powder is 0.05-0.15 micrometer; the grain diameter of silver oxide is 0.05-0.15 micrometer; and the grain diameter of the glass or inorganic oxide is 0.1-5 micrometers. The silver paste is compactly combined with a porcelain body through glue removing and sintering, and problems of external cracks of the porcelain body and internal cracks of the electrode do not occur. The silver paste is low in resistivity, and an inductance product produced by adopting the silver paste is small in DC resistance RDC.

Owner:肇庆市辰业电子有限公司

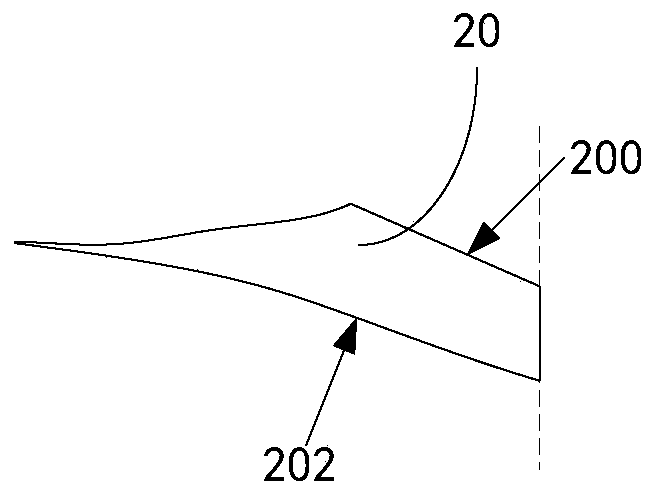

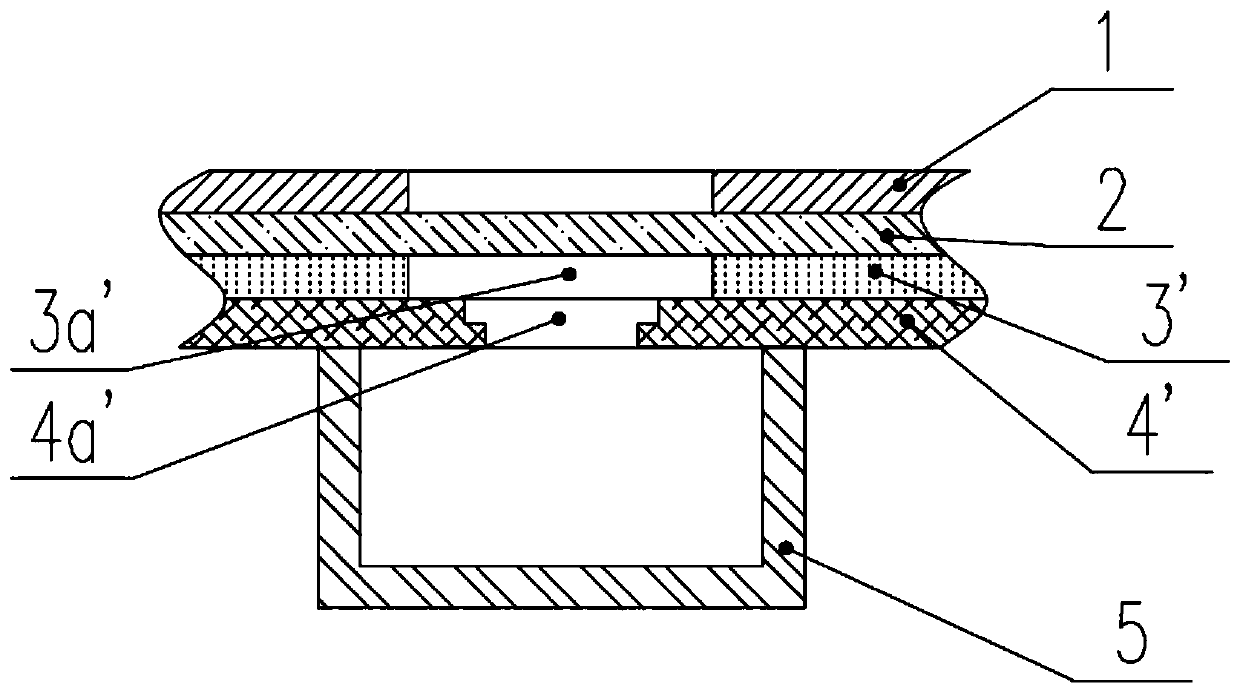

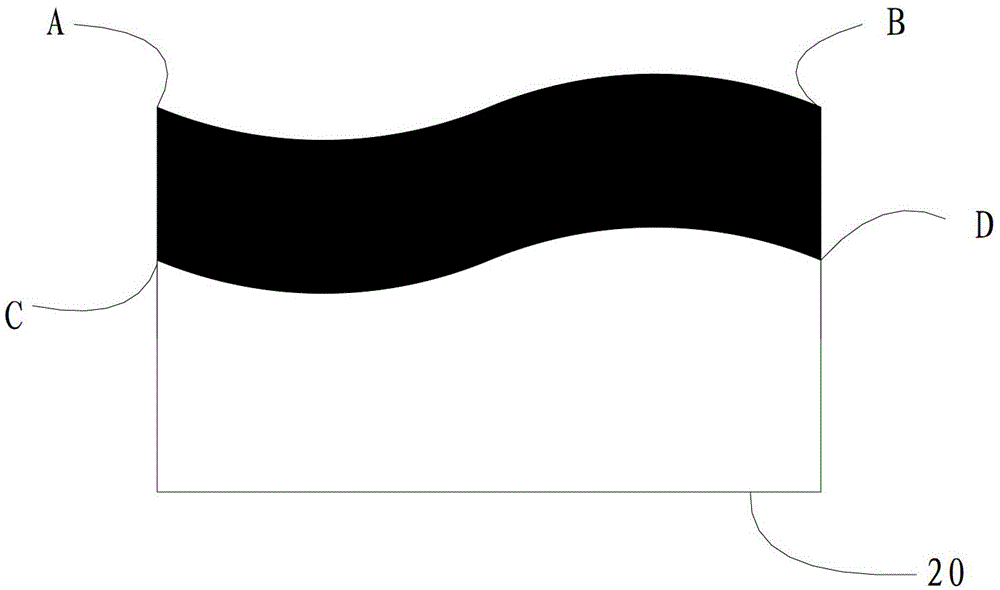

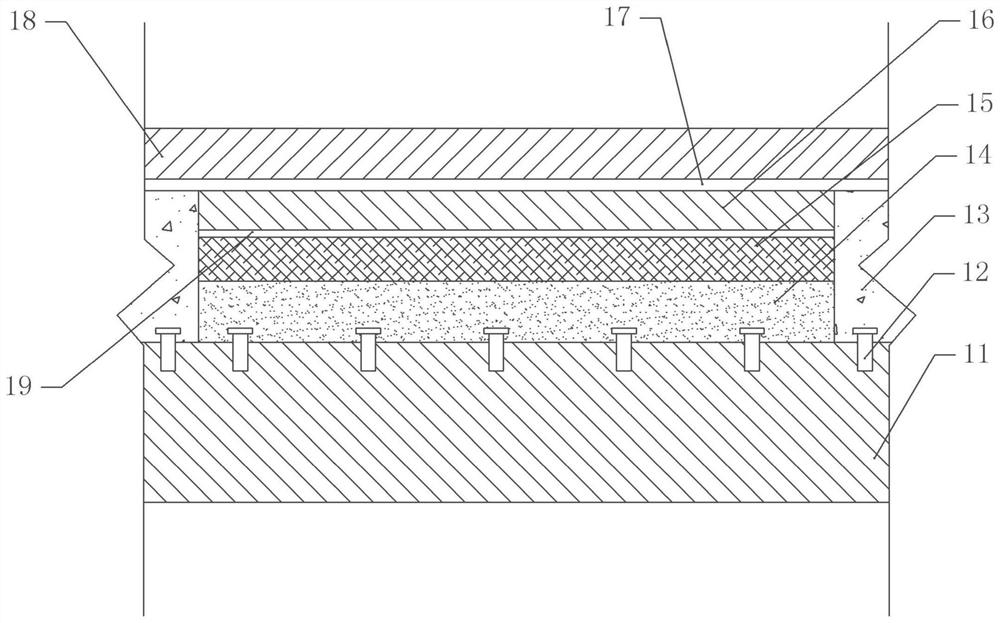

Sandwich glass hot-pressing method and device

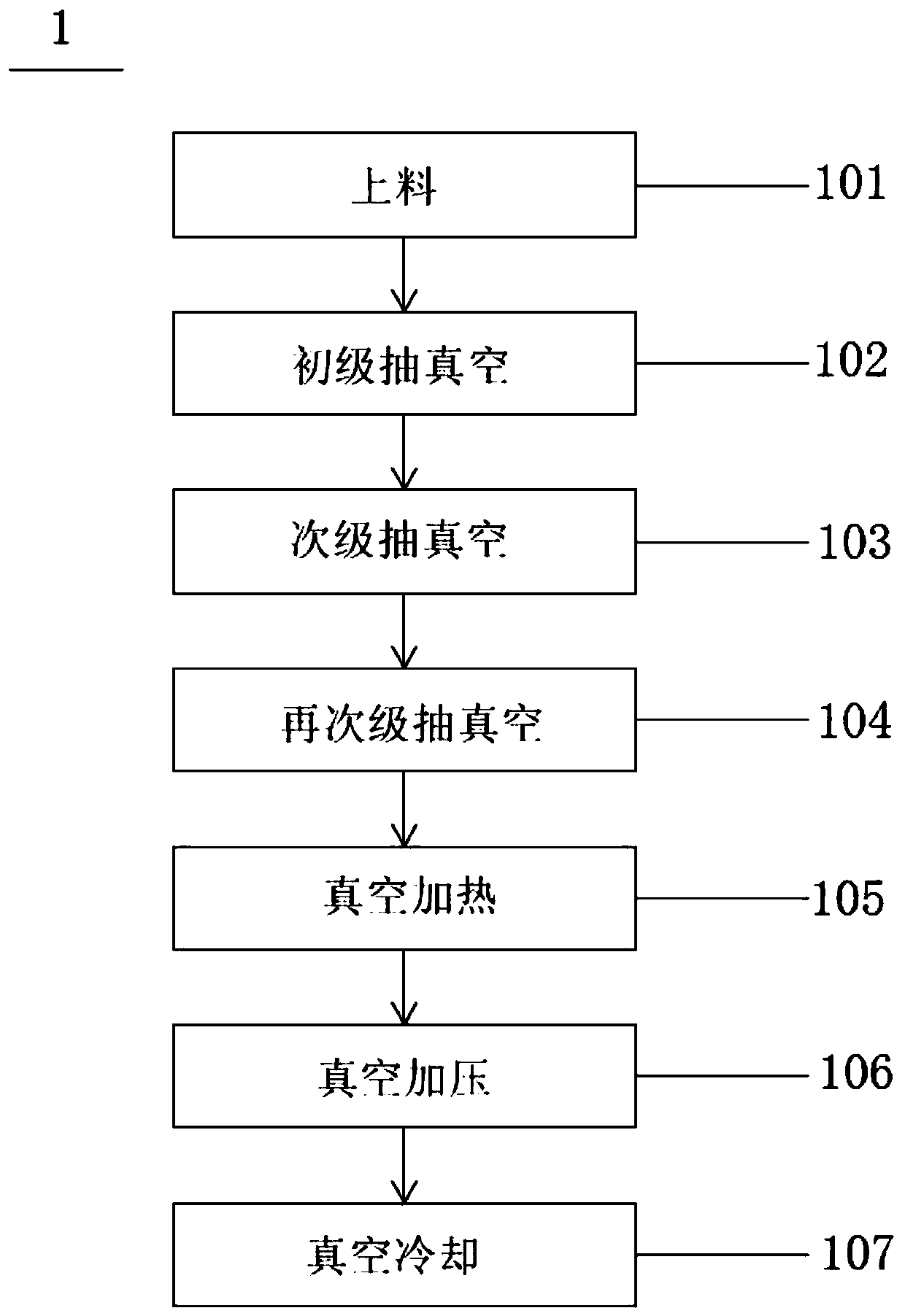

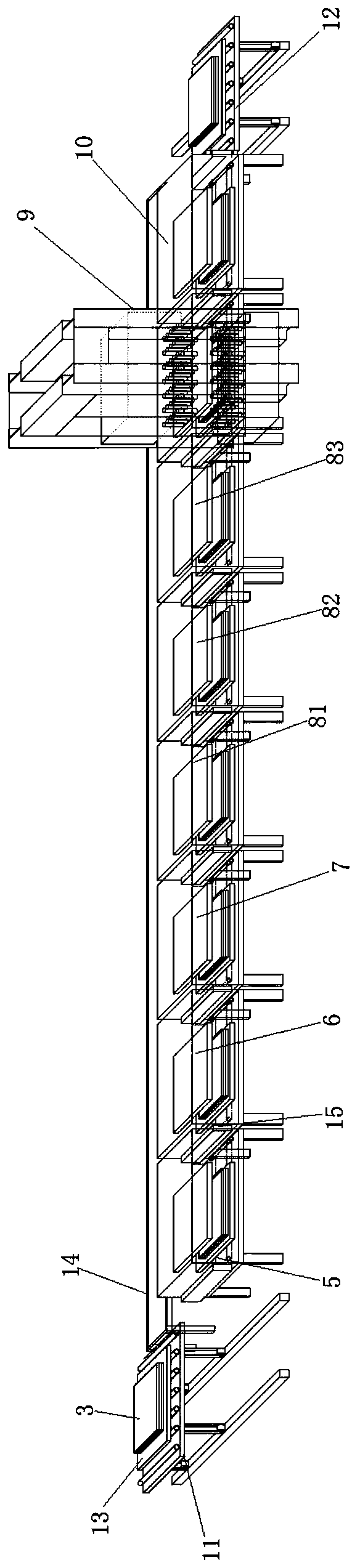

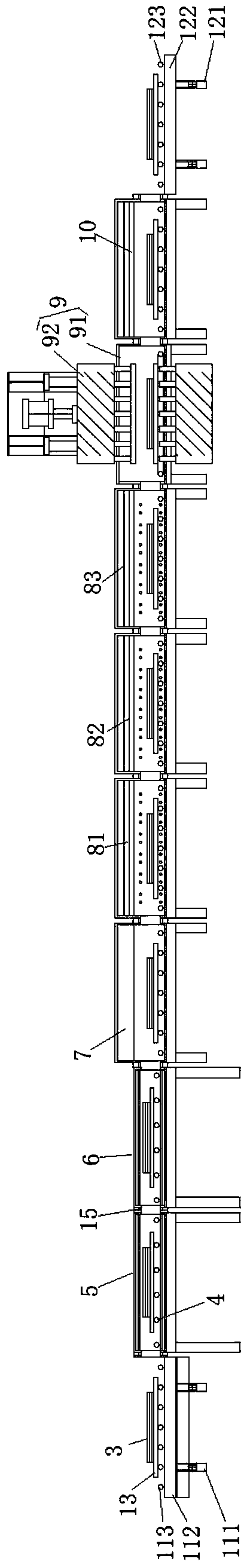

ActiveCN109733045AReduce the presence of air bubblesReduce the chance of delaminationLaminationLamination apparatusEngineeringVacuum chamber

The invention relates to a sandwich glass hot-pressing method and device. The sandwich glass hot-pressing method comprises the following steps of placing laminated multiple-layer glass onto a conveying device; conveying the multiple-layer glass to a rough vacuum chamber, communicating the rough vacuum chamber with a vacuum transitional chamber, vacuumizing the laminated multiple-layer glass to 100-1000 Pa, and maintaining the pressure for 3-5 minutes; conveying the laminated multiple-layer glass to the vacuum transitional chamber, disconnecting the rough vacuum transitional chamber from the vacuum transitional chamber, communicating the vacuum transitional chamber with the high vacuum chamber, vacuumizing the laminated multiple-layer glass to 70-200 Pa, and maintaining the pressure for 3-5minutes; conveying the laminated multiple-layer glass to the high vacuum chamber, disconnecting the vacuum transitional chamber from the high vacuum chamber, communicating the high vacuum chamber with a vacuum heating chamber, vacuumizing the laminated multiple-layer glass to 30-50 Pa, and keeping the pressure for 3-5 minutes. The sandwich glass hot-pressing method can achieve vacuumizing of themultiple-layer glass to a high vacuum state through a step-by-step mode, and meanwhile after vacuumizing is completed, achieve heating of the multiple-layer glass to avoid the possibility of bubbles and layering of the multiple-layer glass during subsequent application.

Owner:JIANGSU IRON ANCHOR GLASS LTD BY SHARE LTD

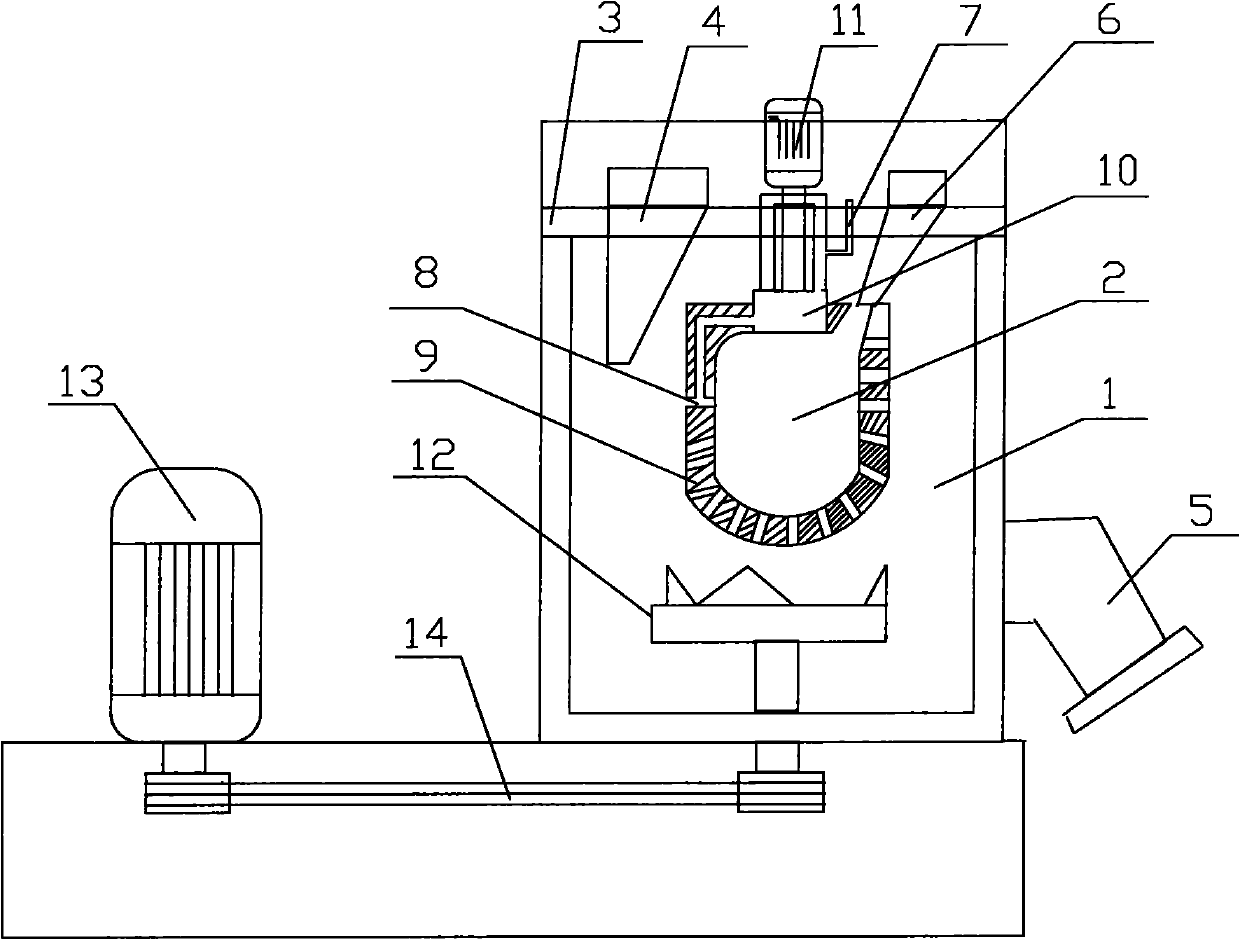

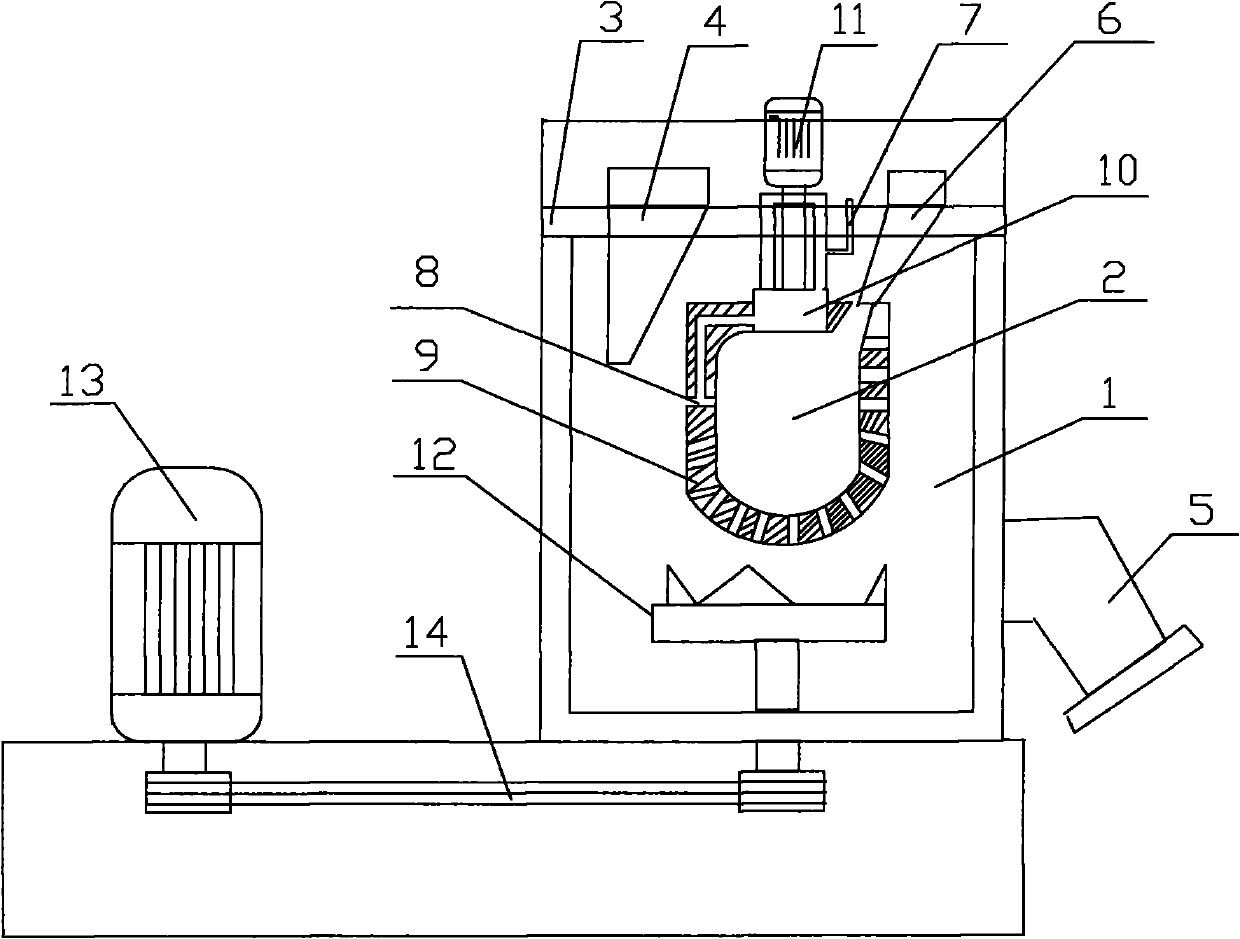

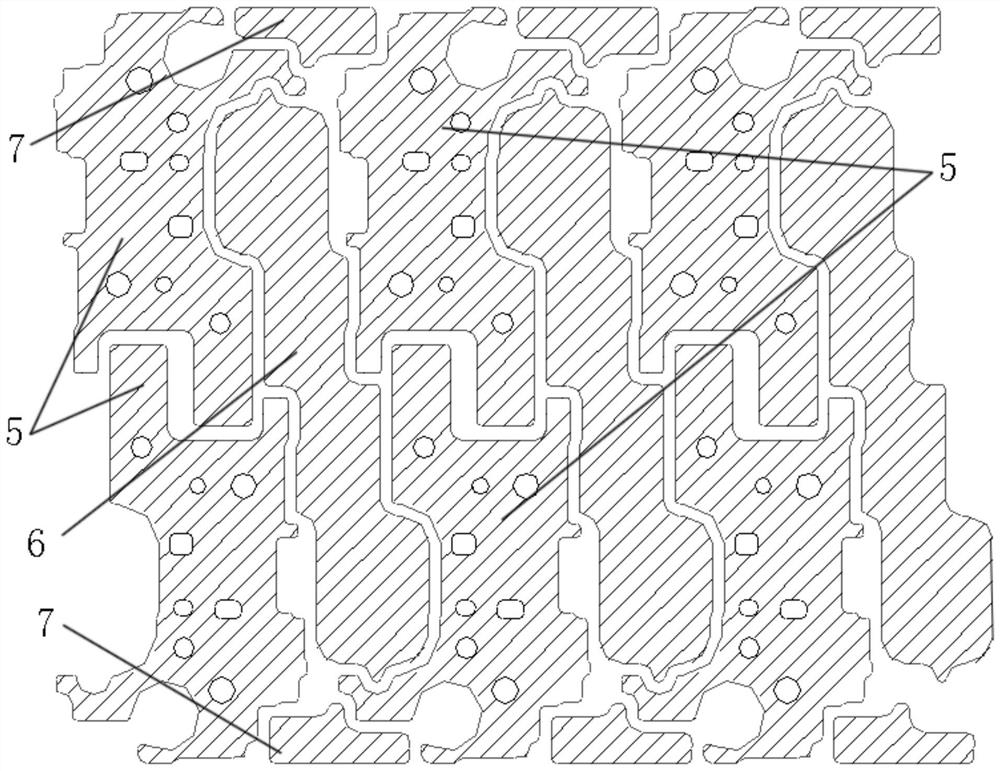

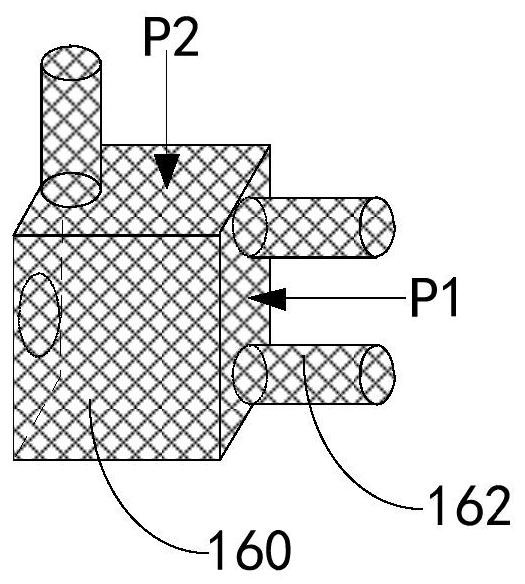

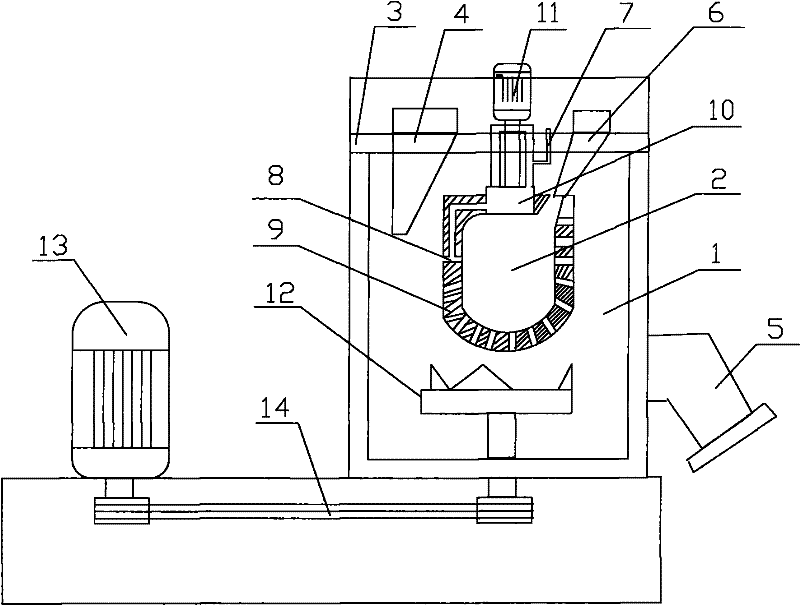

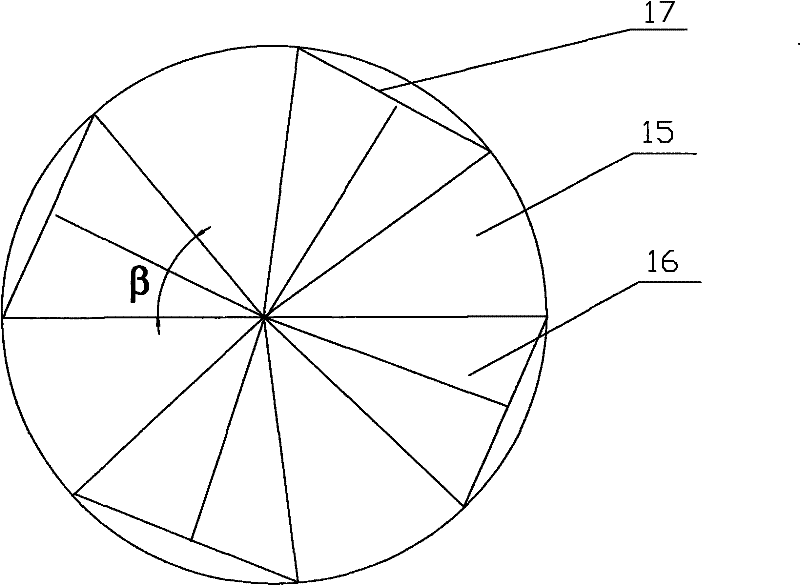

Variable frequency low speed mixer and method for mixing materials with different stacking densities

ActiveCN101905131AAvoid uneven mixingReduce the chance of delaminationMixing methodsMixersLow speedMixed materials

The invention provides a variable frequency low speed mixer and a method for mixing materials with different stacking densities. The mixer comprises a main mixing chamber and an auxiliary mixing chamber, wherein the auxiliary mixing chamber is arranged in the main mixing chamber; a material mixing cover of the main mixing chamber is provided with a granular material feed port; the bottom of the main mixing chamber is provided with an impeller mechanism; the top of the auxiliary mixing chamber is provided with a powdery material feed port and a liquid material feed port; the wall of the auxiliary mixing chamber is provided with a liquid material discharge port and a plurality of powdery material discharge ports; the top of the auxiliary mixing chamber is provided with a liquid material temporary storage chamber which is communicated with the liquid material feed port and the liquid material discharge port; and by the method, the granular material or preliminarily mixed material is threw up by using the main mixing chamber and the powdery material or the liquid material is scattered in the main mixing chamber by using the auxiliary mixing chamber, so various materials with large stacking density difference are mixed uniformly. The mixer and the method can effectively prevent the phenomenon of non-uniform mixing of the materials, realize premixing with good effect and reduce the probability of demixing of the granular material and the powdery material while greatly shortening the mixing time.

Owner:合诚技术股份有限公司

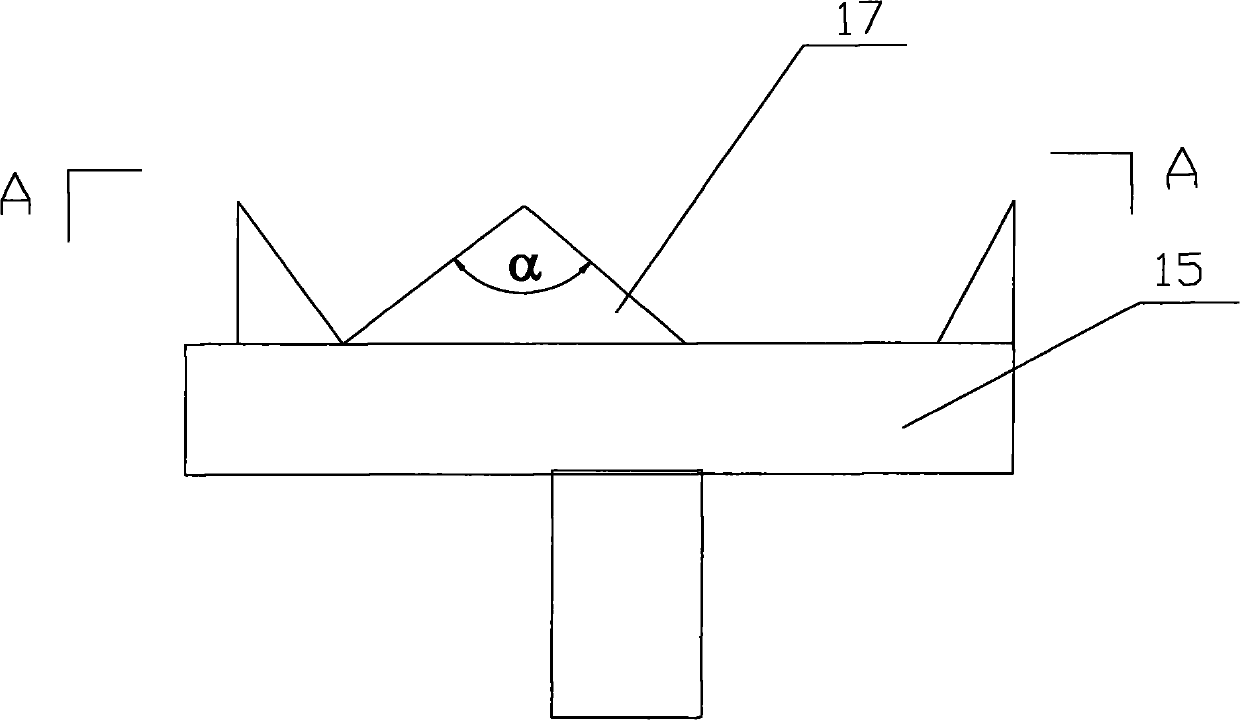

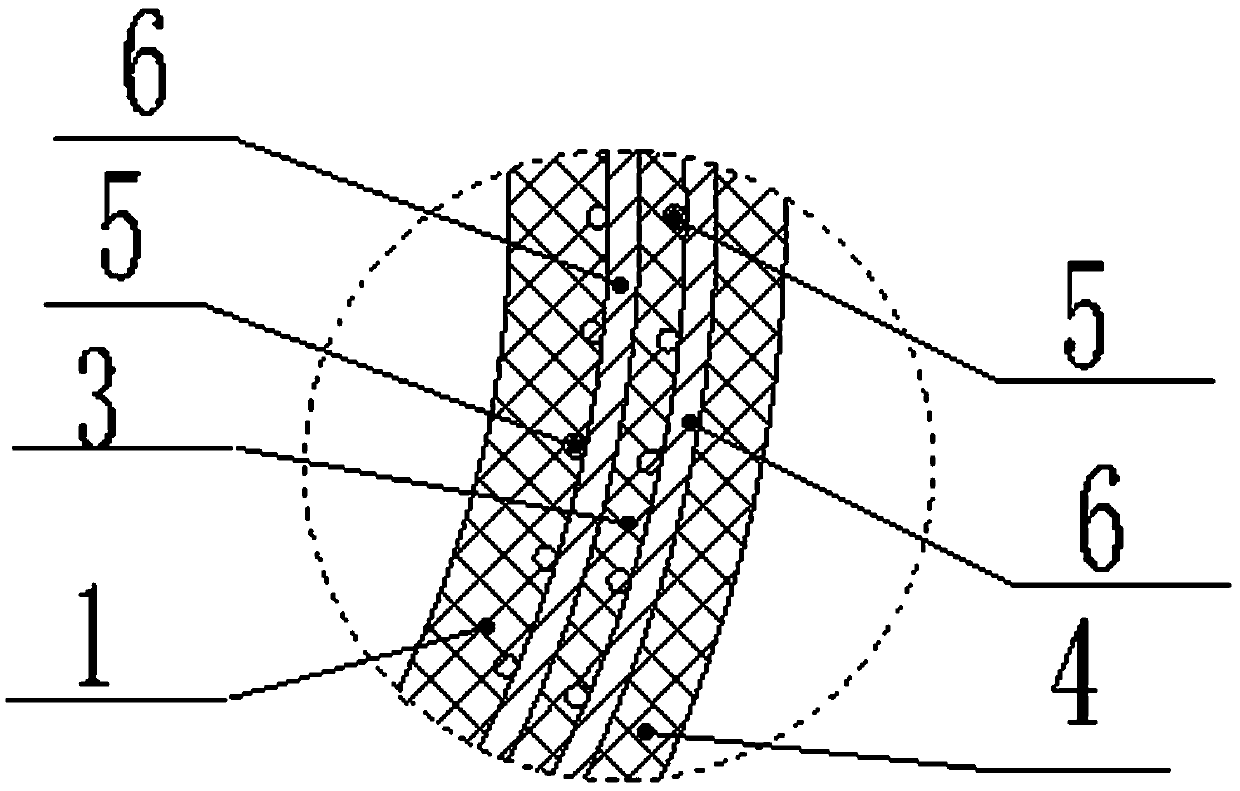

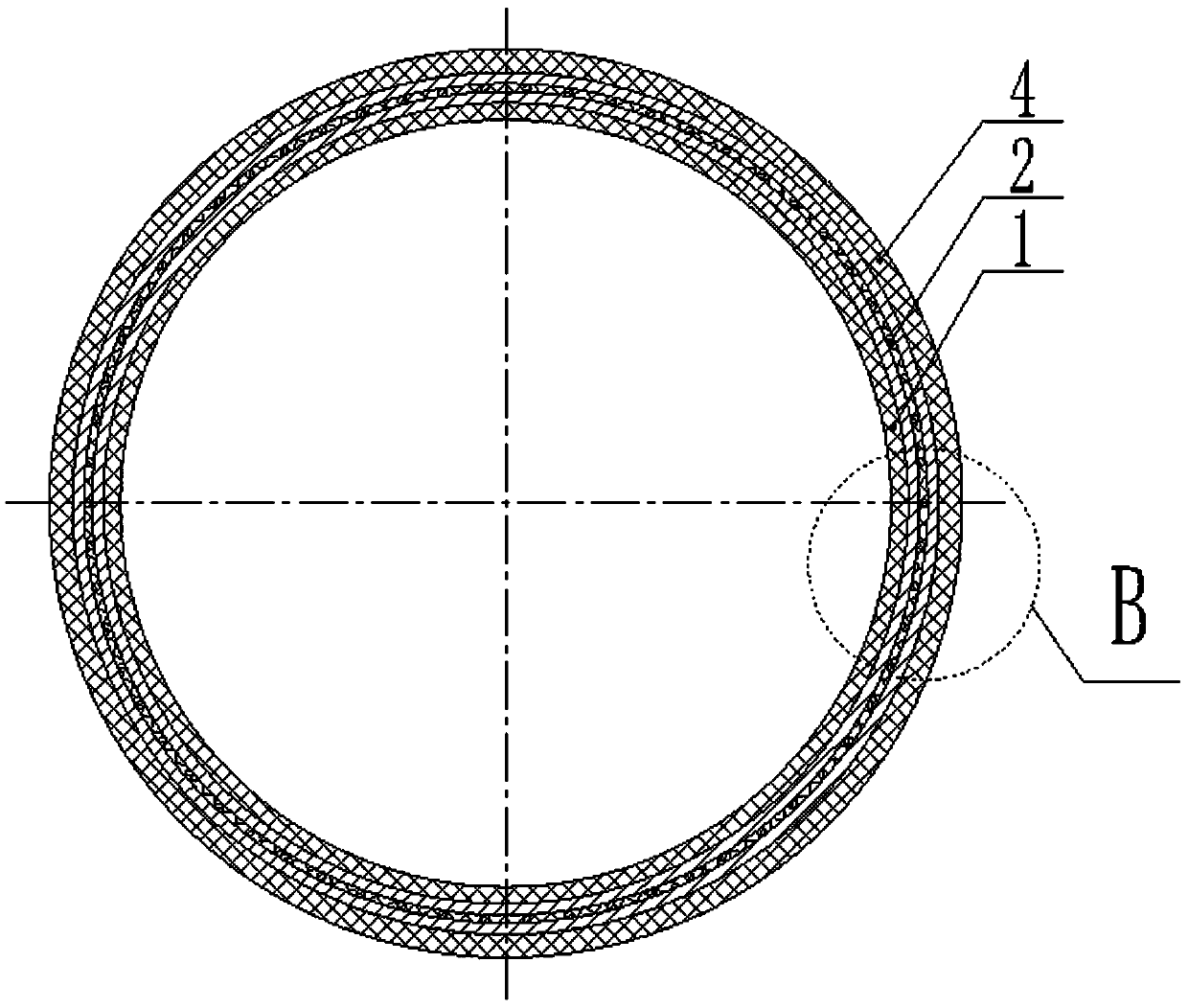

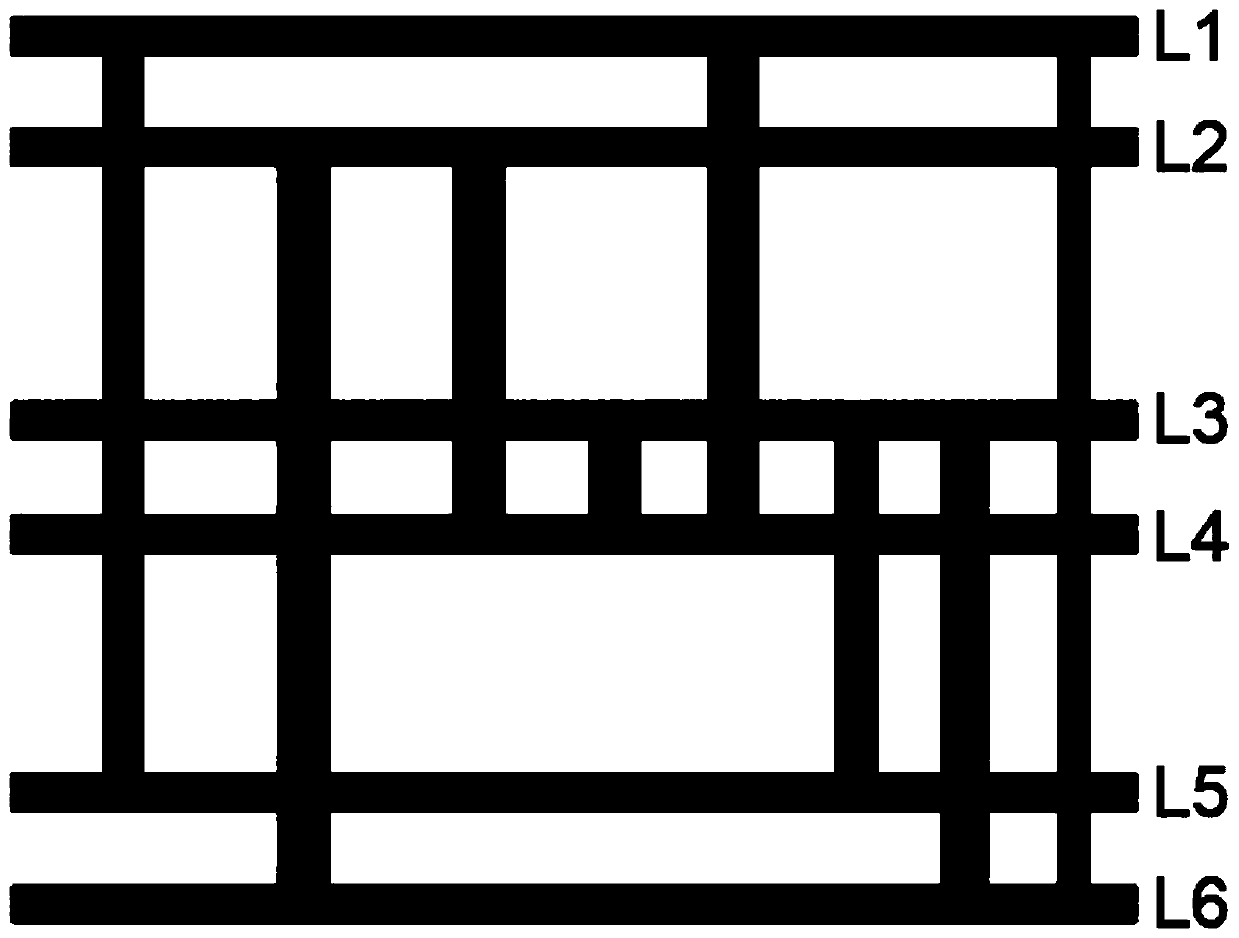

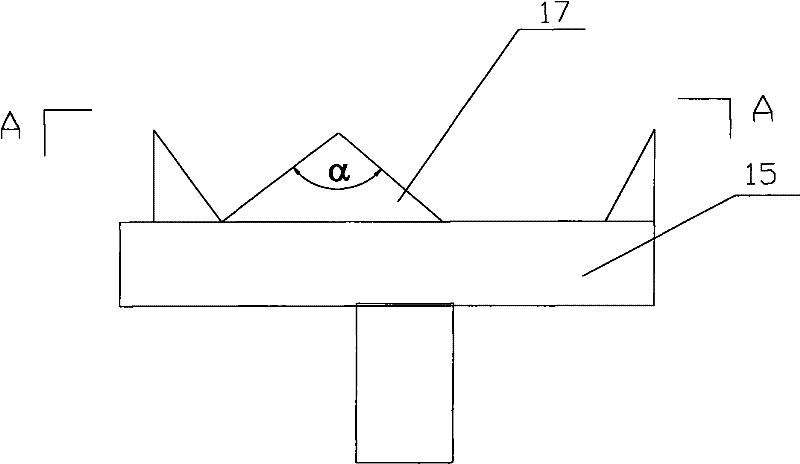

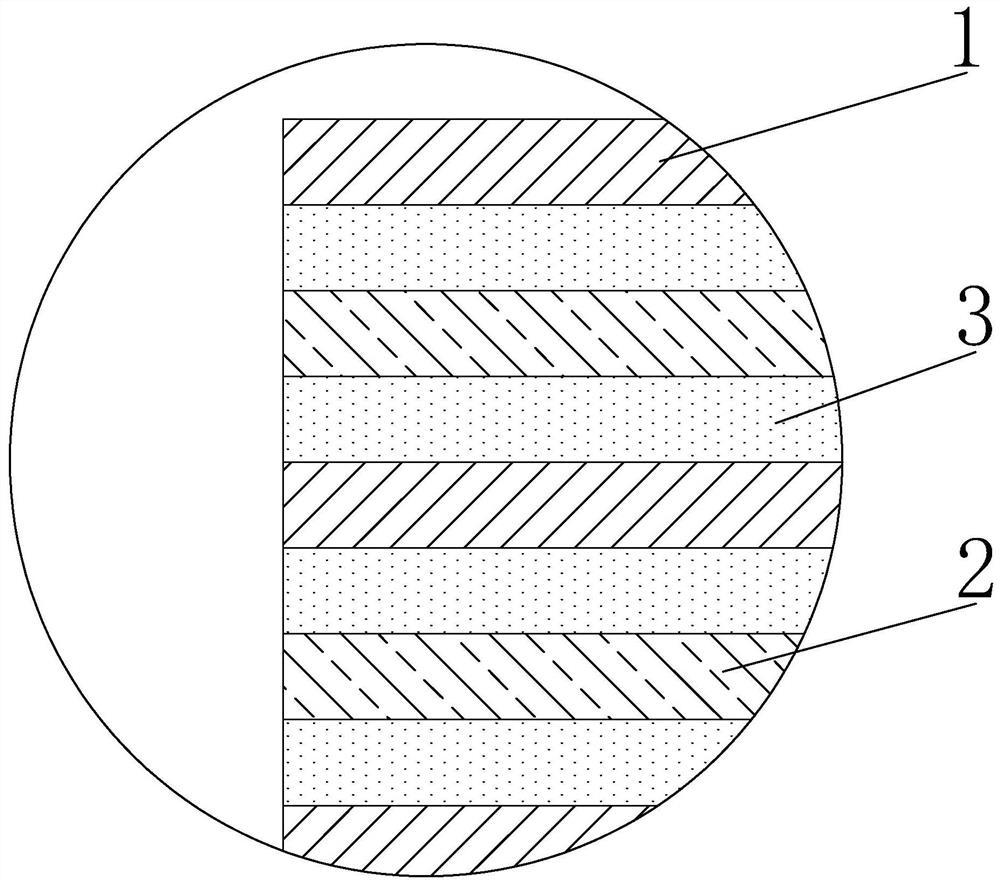

Multi-layer framework reinforced plastic composite pipe

PendingCN111219542AImprove pressure bearing capacityIncrease wall thicknessRigid pipesPipe protection against damage/wearPipeMesh grid

The invention discloses a multi-layer framework reinforced plastic composite pipe which comprises a pipe body formed through the extrusion molding technology, wherein at least two layers of reinforcedframeworks are fixed between the inner wall and the outer wall of the pipe body through the extrusion molding technology and comprise at least one of a reinforced framework A or a reinforced framework B; the reinforced framework A comprises a plurality of longitude lines arranged in the circumferential direction of the pipe body; the longitude lines extend in the axial direction of the pipe body,are spirally wound through latitude lines in the axial direction of the pipe body, and are fixed through welding; the longitude lines and the latitude lines are steel wires; and the reinforced framework B is a continuous integrated grid structure. The multi-layer framework reinforced plastic composite pipe can improve the pipe loading capacity and organically combines high rigidity of steel withnon-corrosibility of plastic; the pipe with relative smaller wall thickness can meet the pressure using requirement, and the excellent characteristics of the plastic pipe are also kept. The multi-layer framework reinforced plastic composite pipe is suitable for the technical field of performance reinforcement of the composite pipe during the production process of plastics-steel composite pipes.

Owner:HUACHUANG TIANYUAN IND DEVING

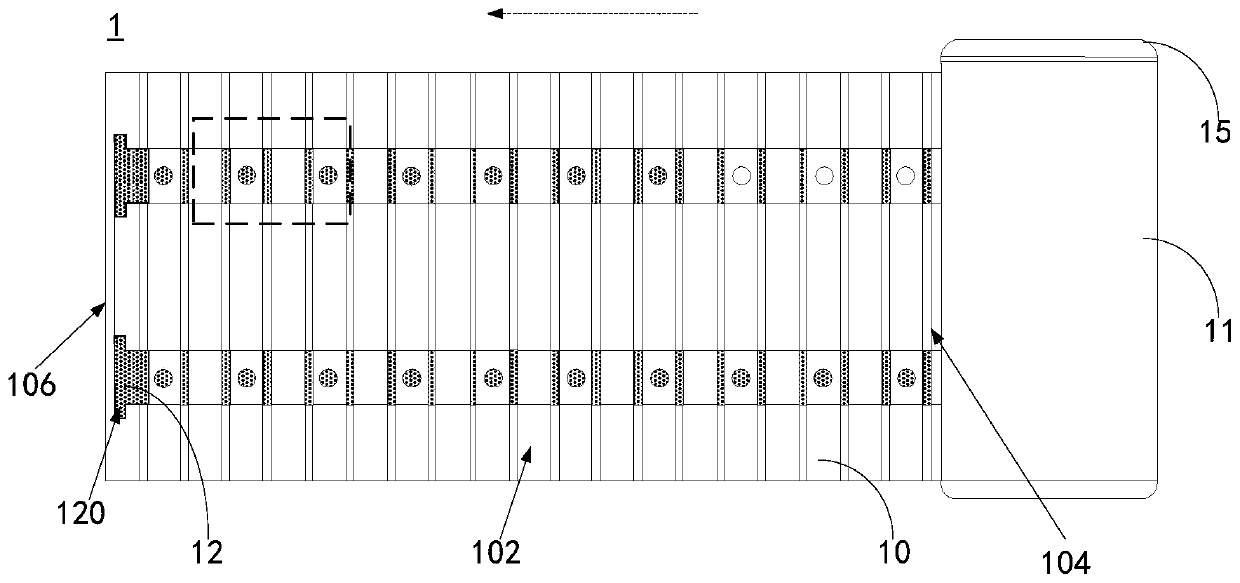

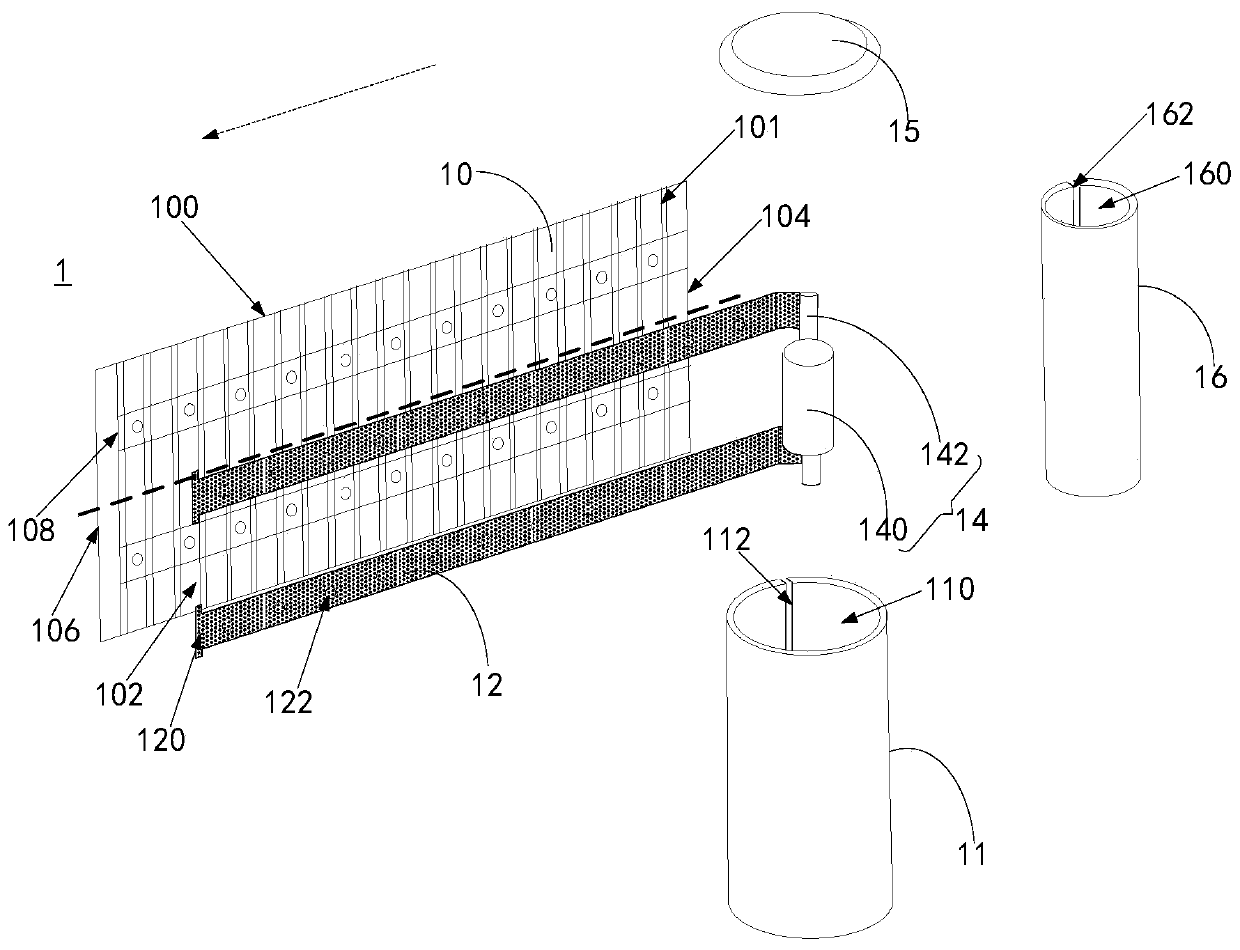

Winding mechanism and winding type display terminal

ActiveCN110634407AReduce the chance of delaminationExtended service lifeIdentification meansConductor CoilMechanical engineering

The invention discloses a winding mechanism and a winding type display terminal. The winding mechanism comprises a flexible support part, a pull strip / pull strips and a driving assembly, wherein the flexible support part comprises a first surface and a second surface opposite to each other, and the first surface is used for arranging a flexible screen; the pull strip / pull strips extends / extend along the direction from the winding initial end to the winding tail end of the flexible support part, and is / are connected with the flexible support part; and the driving assembly comprises a first drive part and a second drive part / second drive parts, the first drive part is used for driving the flexible support part and the flexible screen to wind, the second drive part / second drive parts is / are used for driving the pull strip / pull strips to wind, so that in the process that the flexible support part winds, the flexible support part is tensioned towards the winding initial end, and further, the winding stroke of the flexible support part is greater than the winding stroke of the flexible screen. Through the mode, the displacement differences among a plurality of film layers of the flexiblescreen can be reduced, and further, the purpose of protecting the flexible screen is achieved.

Owner:YUNGU GUAN TECH CO LTD

Bending-resisting plywood and manufacturing method thereof

PendingCN106738111AReduce the vertical and horizontal strengthLongitudinal and horizontal strength guaranteeWood veneer joiningWood layered productsEngineeringMetal

The invention relates to the field of special plywood applied to the vehicle bottom plate environment which is frequently vibrated and bended, in particular to bending-resisting plywood. The bending-resisting plywood comprises a pressed sawdust layer, a first plate layer and a second plate layer, wherein the first plate layer and the second plate layer are glued on the two sides of the sawdust layer. A metal mesh layer is embedded in the middle of the sawdust layer; and at least two woven mesh layers are symmetrically arranged on the two sides of the metal mesh layer and embedded in the sawdust layer. The thickness of the sawdust layer in the three layers of plates of the structure is convenient to control, the metal mesh layer and the woven mesh layers are arranged in an embedded mode, the metal mesh layer serves as a framework, and the woven mesh layers are arranged on the two sides of the metal mesh layer, so that the integrity of the sawdust layer is improved, the metal mesh layer or the woven mesh layers are prevented from delaminating, saw dust is fully utilized, and the manufacturing cost is reduced by 10%-20% compared with the same kind of plywood.

Owner:曾世涛

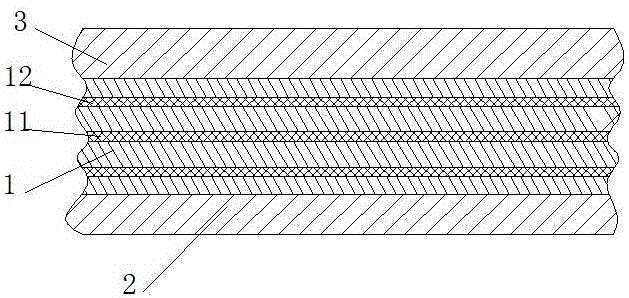

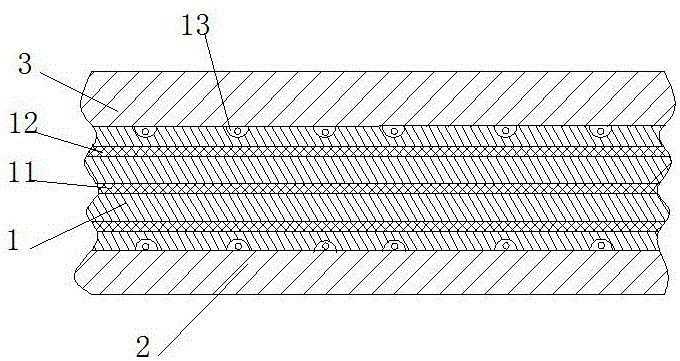

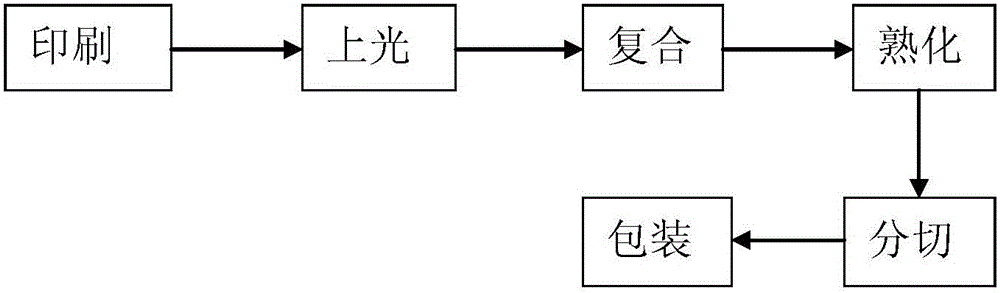

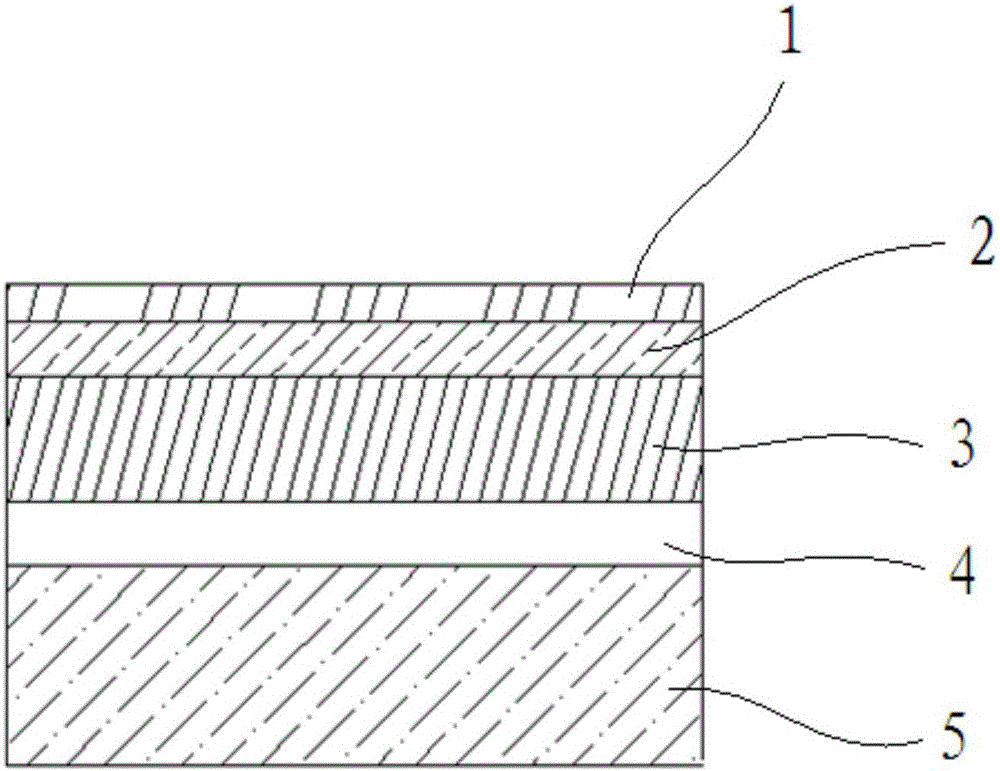

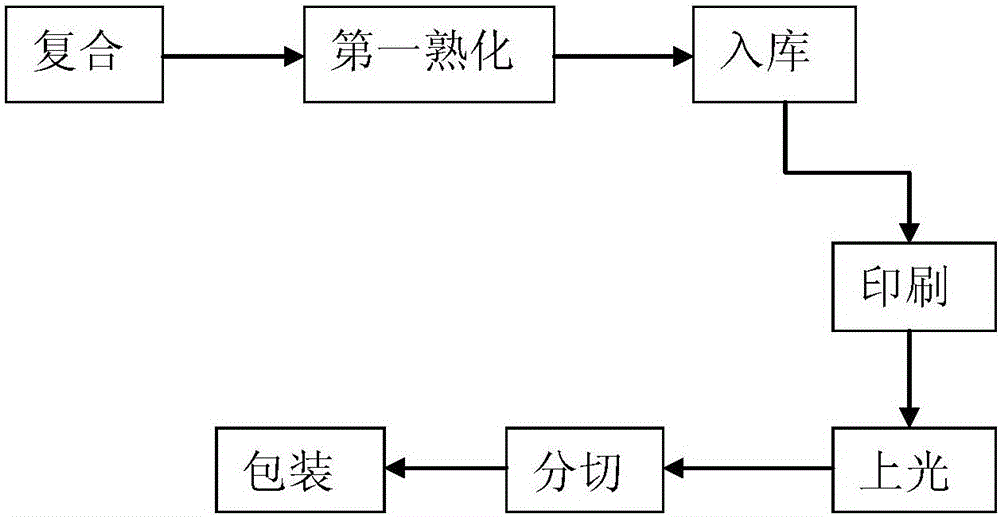

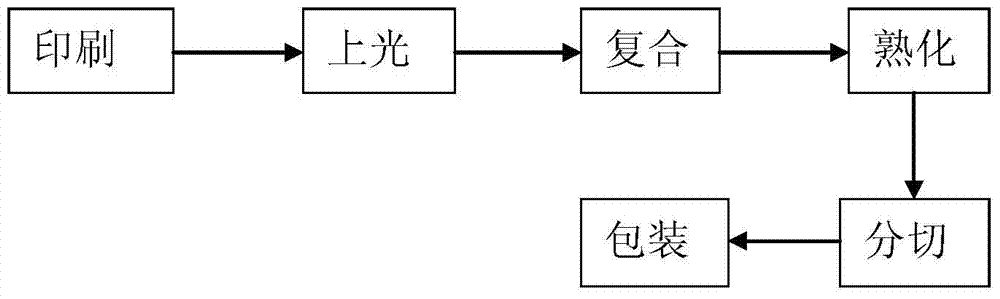

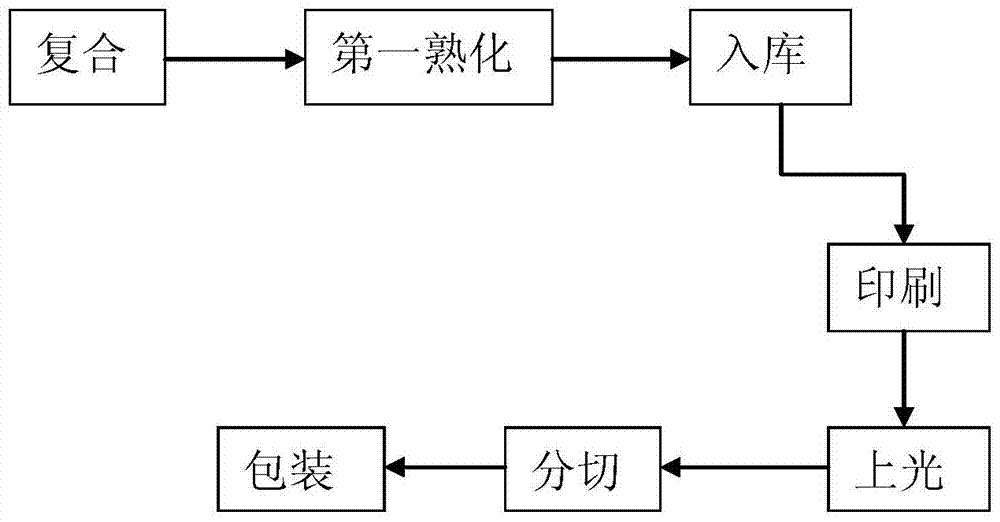

Method for manufacturing aluminum foil sealing film

ActiveCN105129221AHigh composite strengthReduce the chance of delaminationLamination ancillary operationsBio-packagingVarnishAluminum foil

The invention discloses a method for manufacturing an aluminum foil sealing film and belongs to the technical field of sealing film packaging. The method sequentially includes the processes of 1, composting, wherein one face of aluminum foil is coated with a bonding agent, a thermoplastic resin film is composted to the face, with the bonding agent, of the aluminum foil after the aluminum foil is dried, and a composite film is formed; 2, first curing, wherein the composite film is placed in a curing chamber to be cured; 3, warehousing, wherein the cured composite film is stored into a warehouse; 4, printing, wherein when printing is needed, the composite film is taken out from the warehouse, the non-composite face of the aluminum foil of the composite film is printed with selected characters or patterns with oil ink, and drying treatment is conducted; 5, varnishing, wherein the face printed with oil ink of the aluminum foil is coated with varnish; 6, splitting, the varnished composite film is split to be of the required size; and 7, packaging, wherein split composite films are packaged. By means of the method, the technical problems that an existing method for manufacturing an aluminum foil sealing film is long in manufacturing cycle, and the manufactured aluminum foil sealing film is high in layering rate are solved. The method has the beneficial effects of being short in manufacturing cycle, and the manufactured aluminum foil sealing film is low in layering rate.

Owner:ZHEJIANG GOLDSTONE PACKING

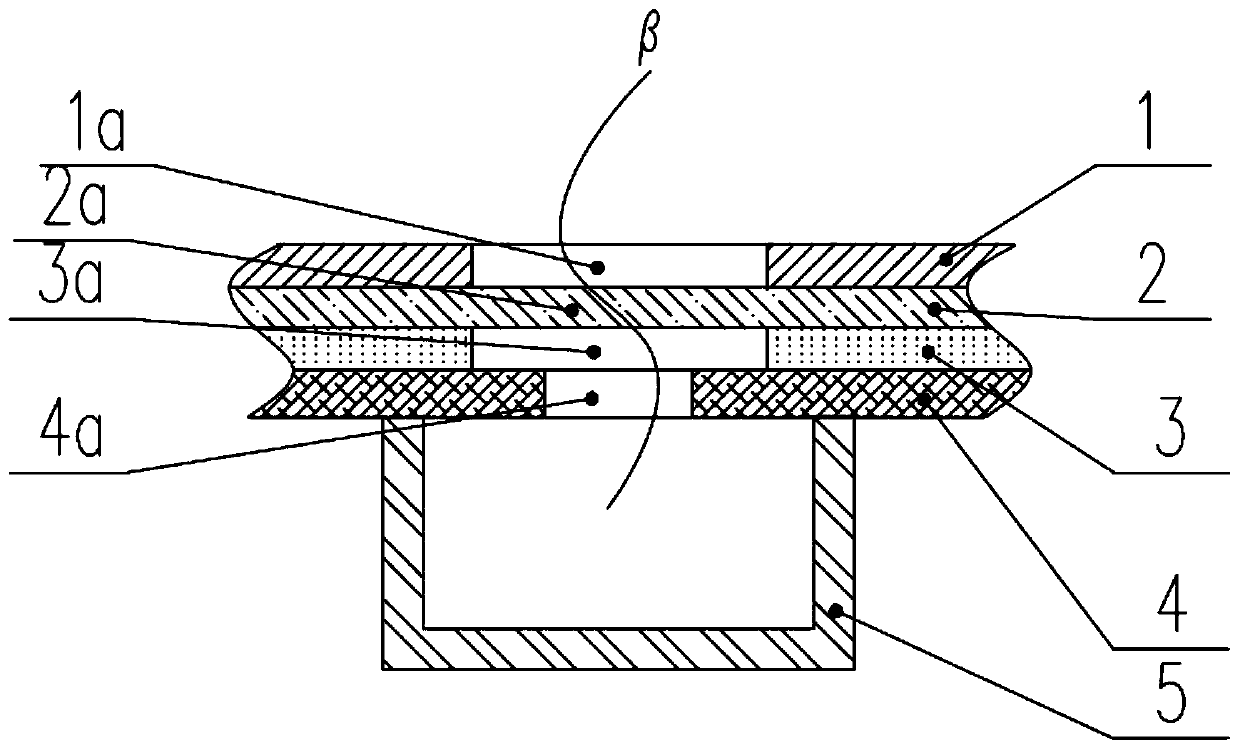

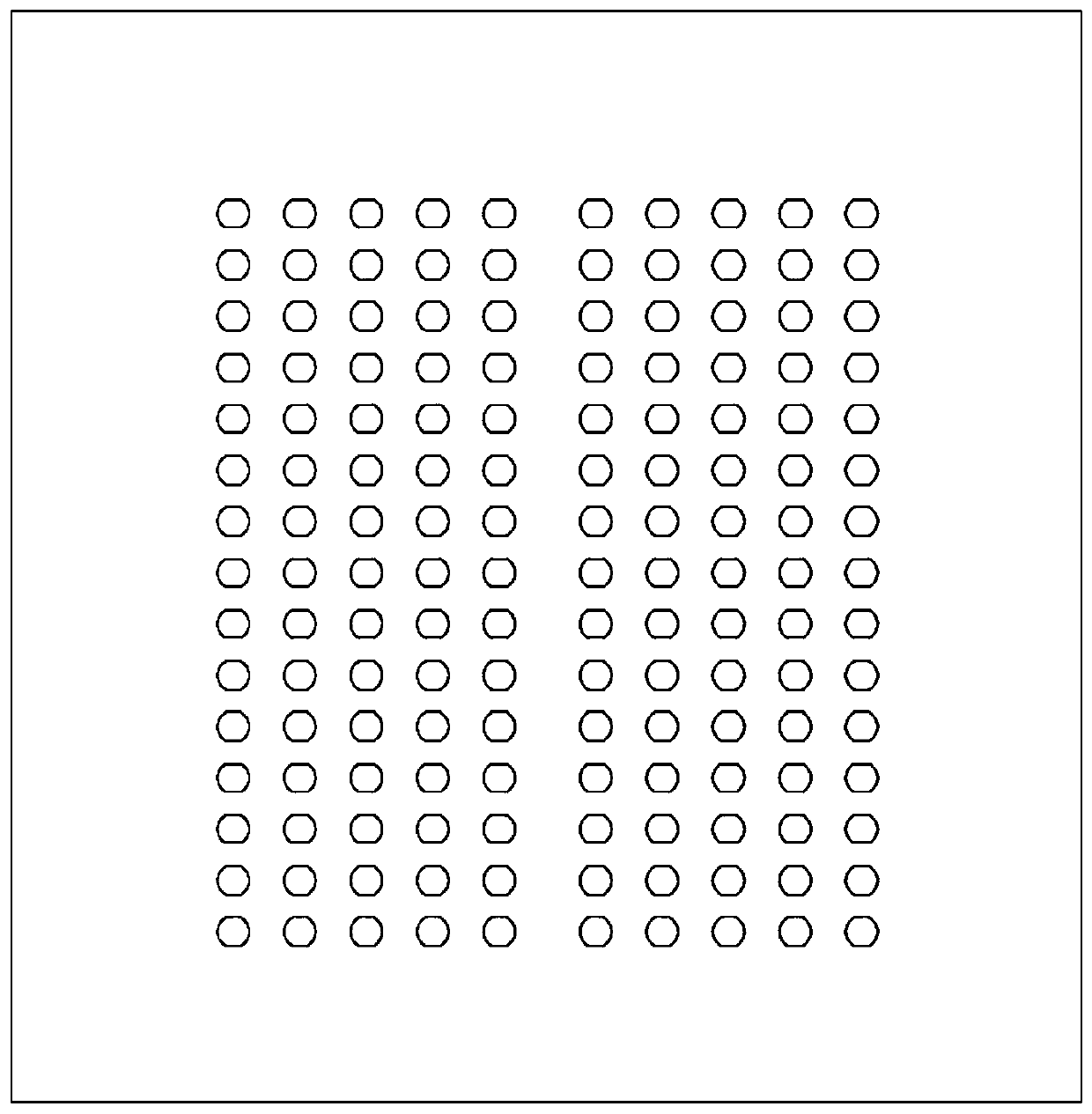

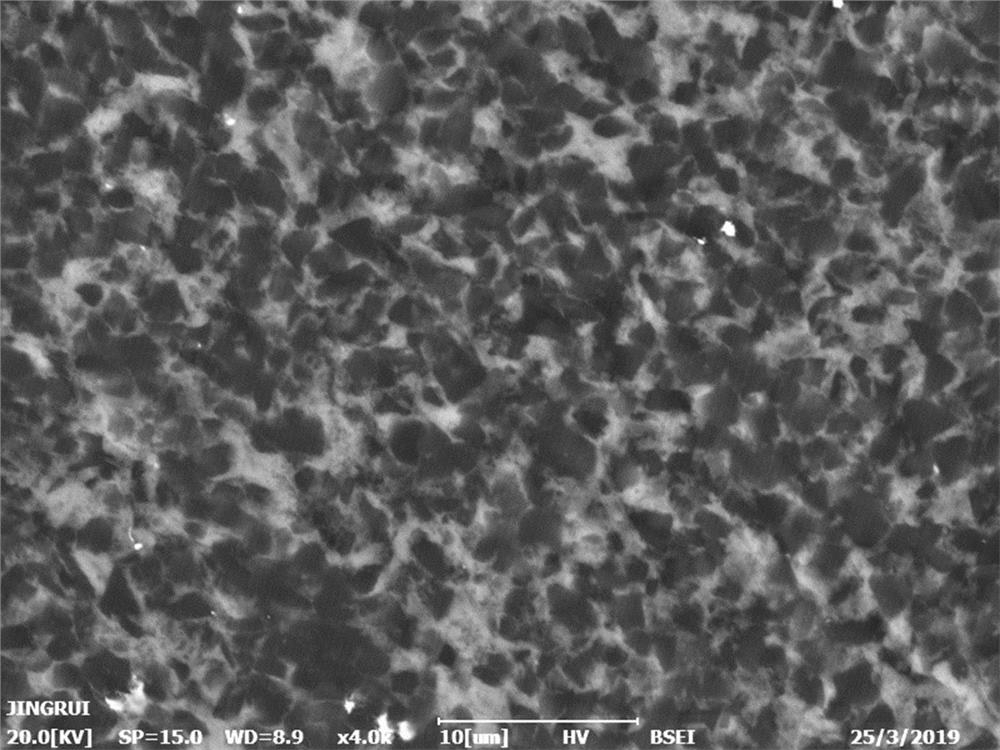

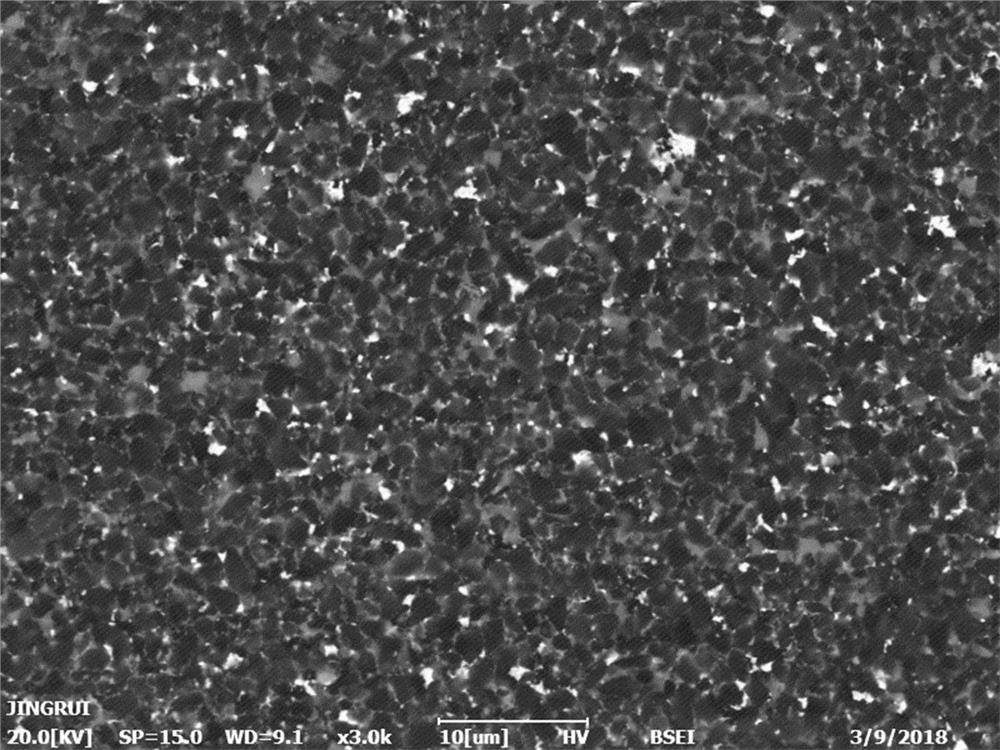

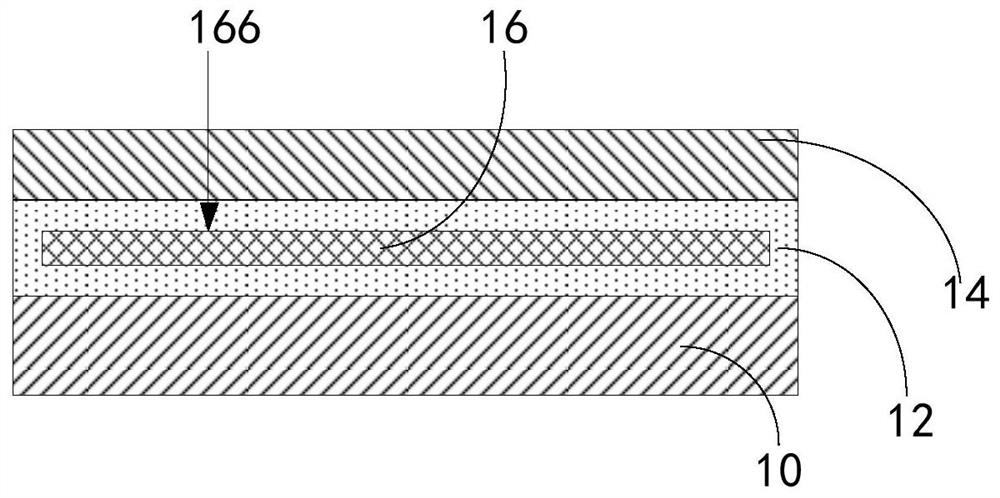

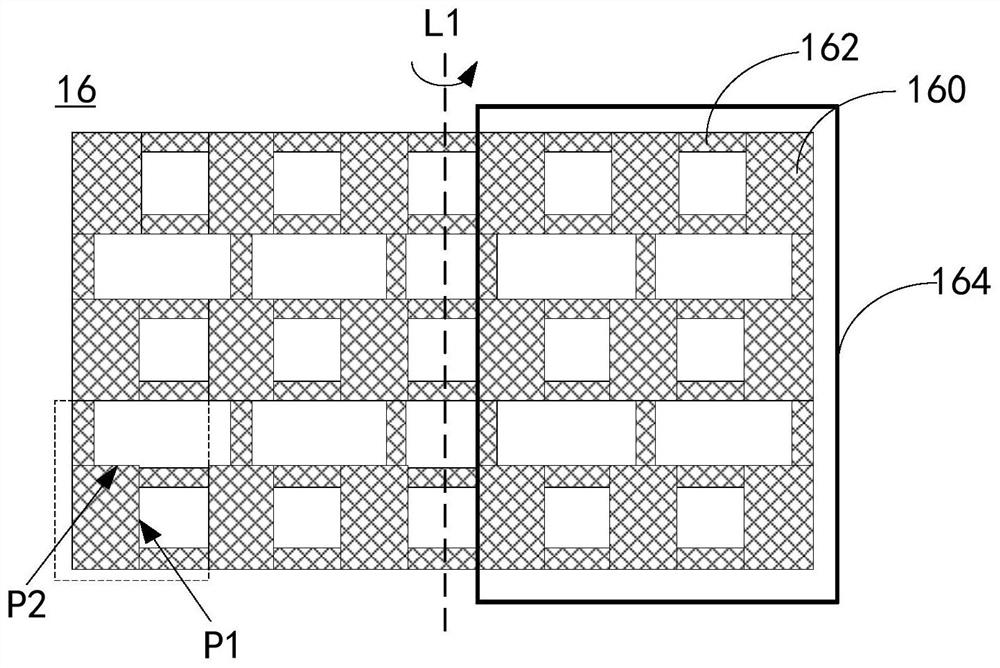

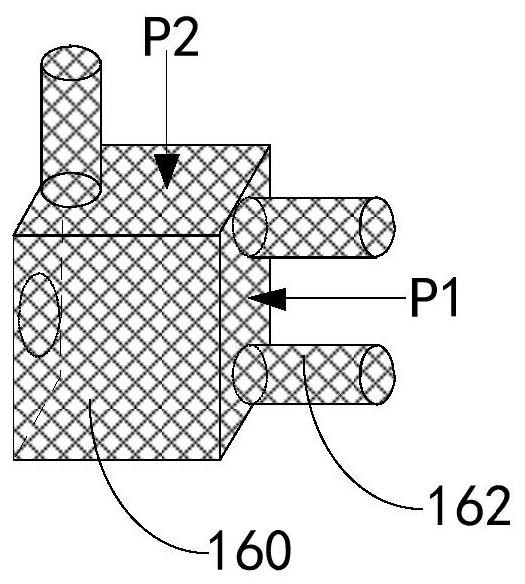

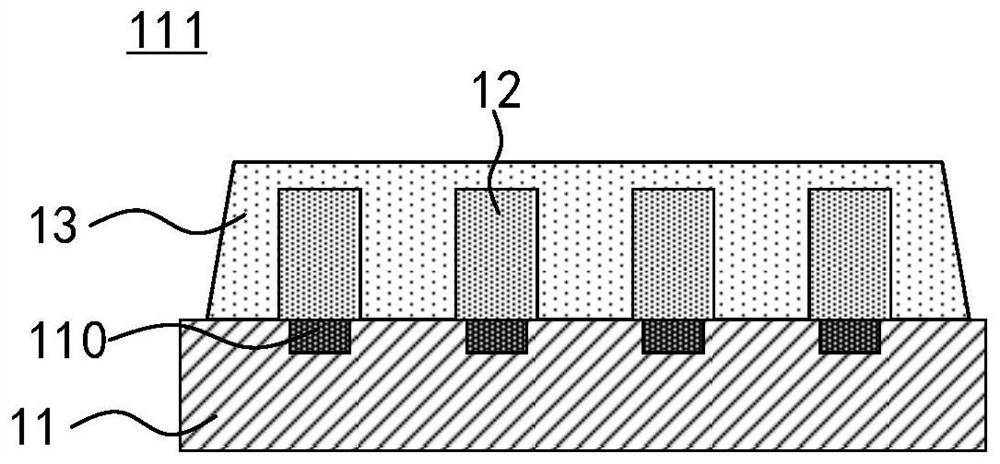

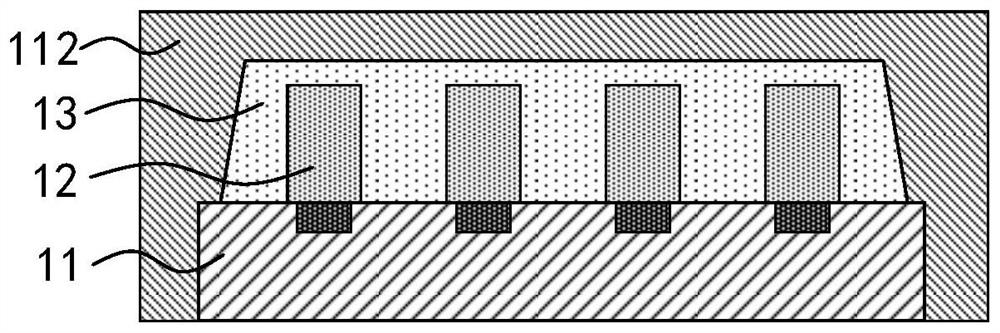

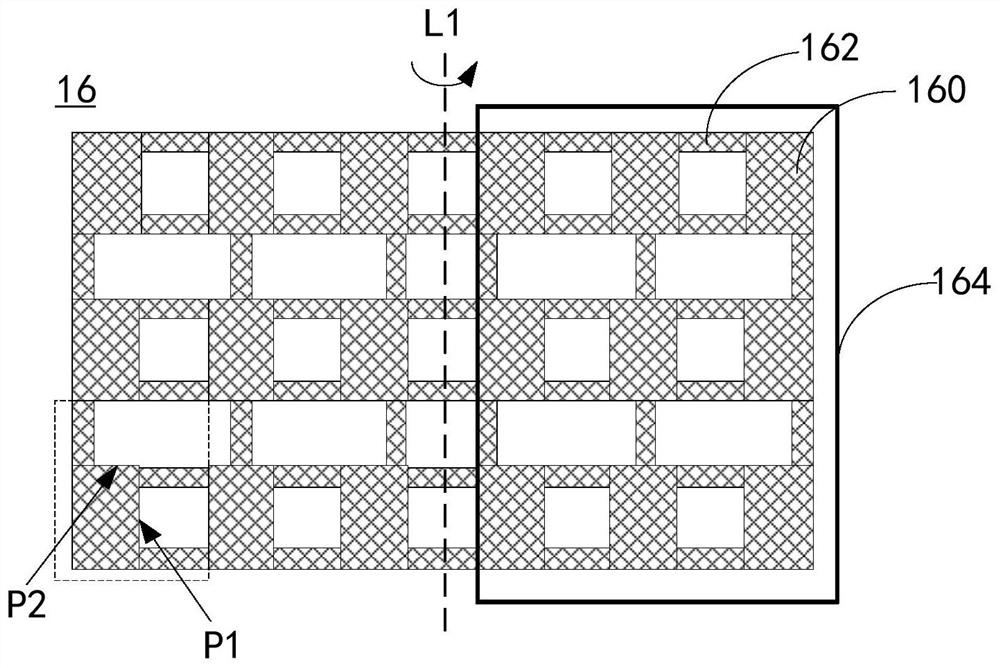

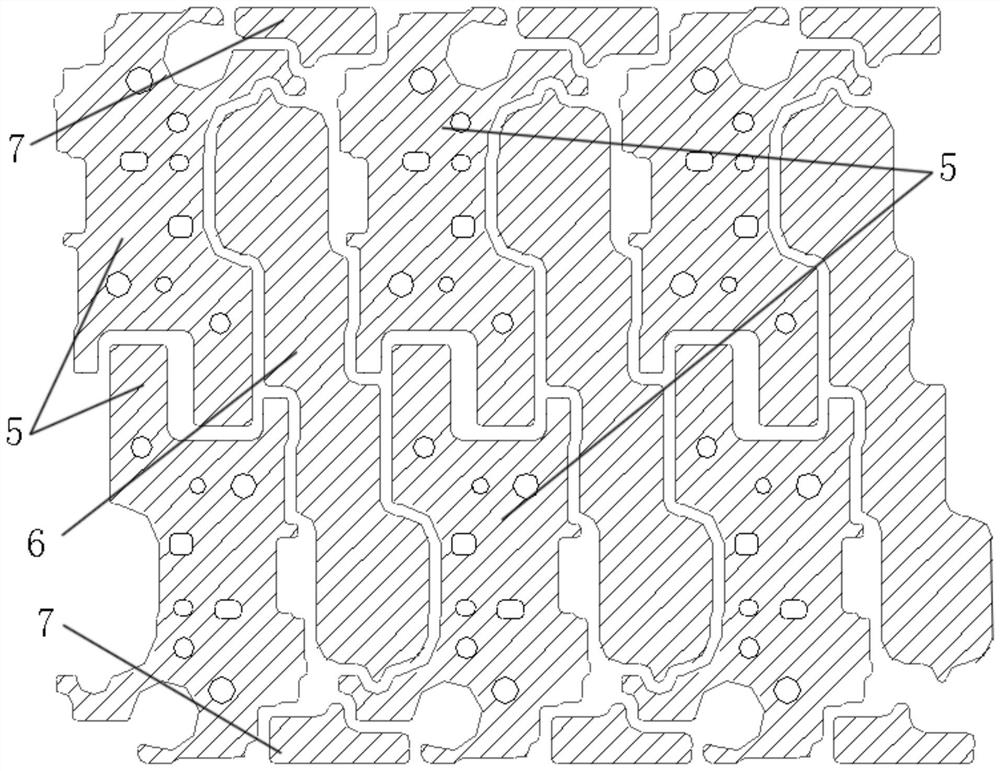

A matrix type structure of a dustproof, waterproof and sound-transmitting film of a micro electro mechanical sensor

PendingCN111601222AWith insertion lossWith water pressure resistanceSemiconductor electrostatic transducersElectrostatic transducer microphonesAcoustic transmissionAdhesive

The invention discloses a matrix type structure of a dustproof, waterproof and sound-transmitting film of a micro electro mechanical sensor. The structure comprises a supporting layer, a dustproof andwaterproof acoustic transmission film, an adhesive, a PCB and acoustic sensors; one face of the supporting layer is adhesive and adheres to one face of the dustproof and waterproof acoustic transmission film, the other face of the dustproof and waterproof acoustic transmission film adheres to the upper surface of the PCB through the adhesive, and the acoustic sensors are installed on the lower surface of the PCB; the acoustic sensors, the support layer sound hole, the dustproof and waterproof acoustic transmission film vibration area, the adhesive sound hole and the PCB sound hole form an acoustic channel; the multiple acoustic sensors are distributed on the lower surface of the PCB in a matrix mode, so the matrix type dustproof, waterproof and sound-transmitting film structure is correspondingly formed; the waterproof film adheres to the PCB through an adhesive, and batch products can be produced at a time. The acoustic sensors are covered with the expanded polytetrafluoroethylene film formed by the highly-fibrillated ePTFE microstructure, and the structure has the insertion acoustic loss lower than 5 dB under 1 kHz and the water pressure resistance of at least one meter or above.

Owner:苏州孝义家光电科技有限公司

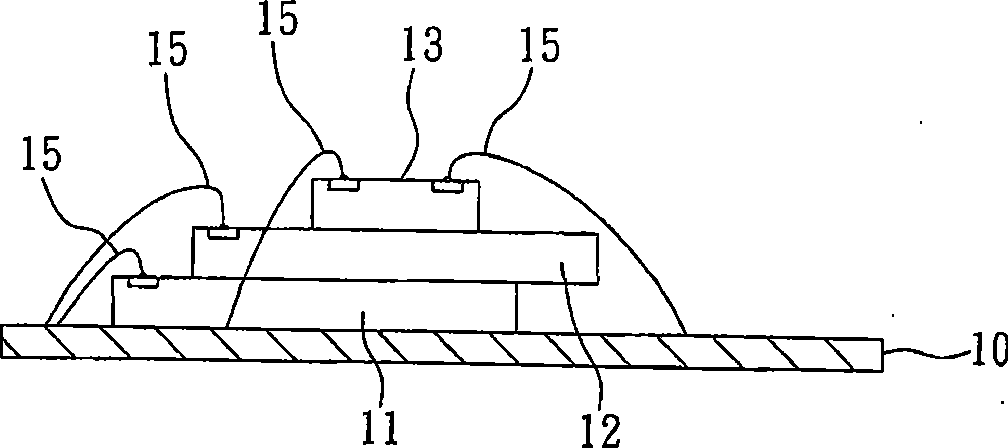

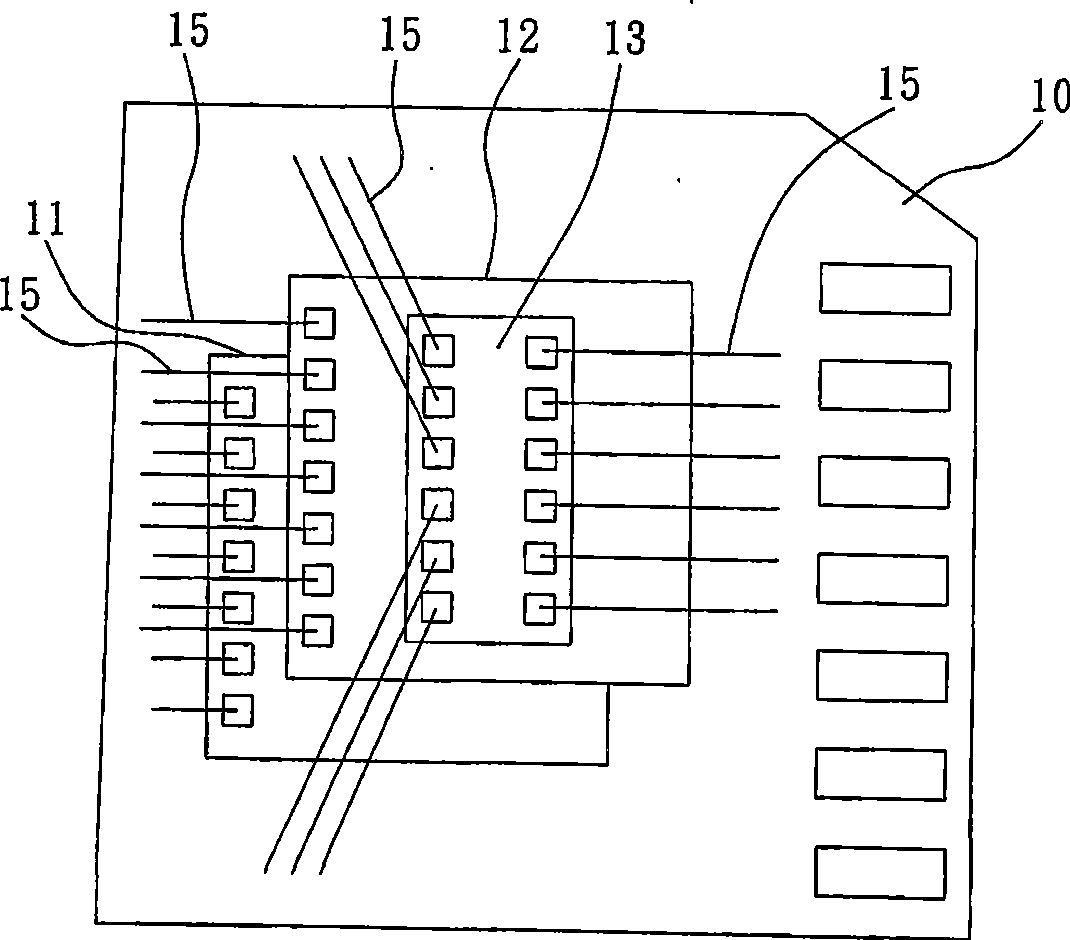

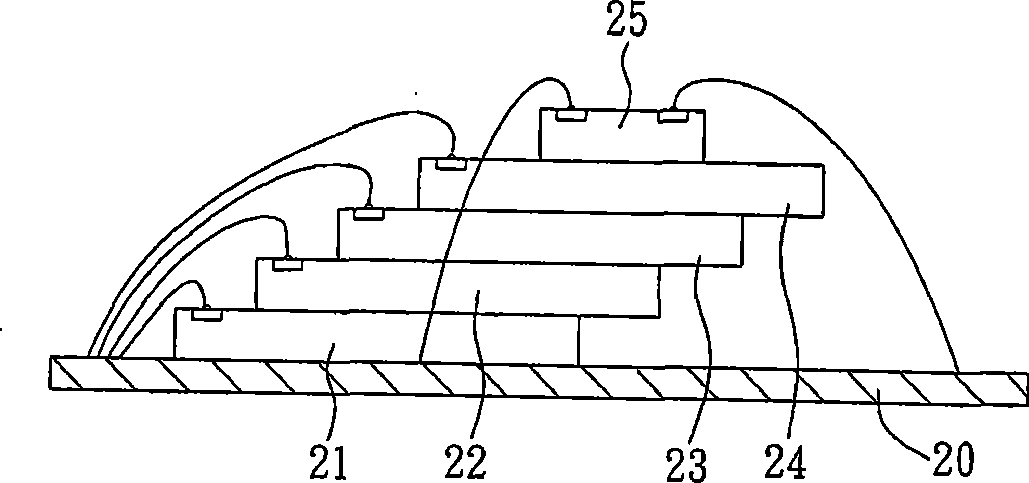

Multi-chip stacking structure and preparation thereof

ActiveCN101452861AIncrease the number of stacked layersAvoiding the problem of increasing structural heightSemiconductor/solid-state device detailsSolid-state devicesState of artChip stacking

The invention discloses a multichip stacking structure and a method for manufacturing the same. The multichip stacking structure comprises a first chip set which is provided with a plurality of first chips and is connected with a chip bearing piece in a stepped mode; the first chip of the topmost layer of the first chip set is connected with a second chip so that the first chip and the second chip are in electric connection with the chip bearing piece through a welding wire; adhesive film over wire technology (Film over Wire, FOW) is utilized to stack a third chip alternated with an insulating adhesive film on the first chip and the second chip so that the insulating adhesive film covers part of the welding wire end of the first chip of the topmost layer of the first chip set and at least one part of the second chip and is in electric connection with the third chip and the chip bearing piece through the welding wire, thereby solving the problem that when the second chip with planar dimension far less than that of the first chip is directly stacked on the first chip in the prior art, the height of the whole structure and the difficulty of wire welding operation are increased.

Owner:SILICONWARE PRECISION IND CO LTD

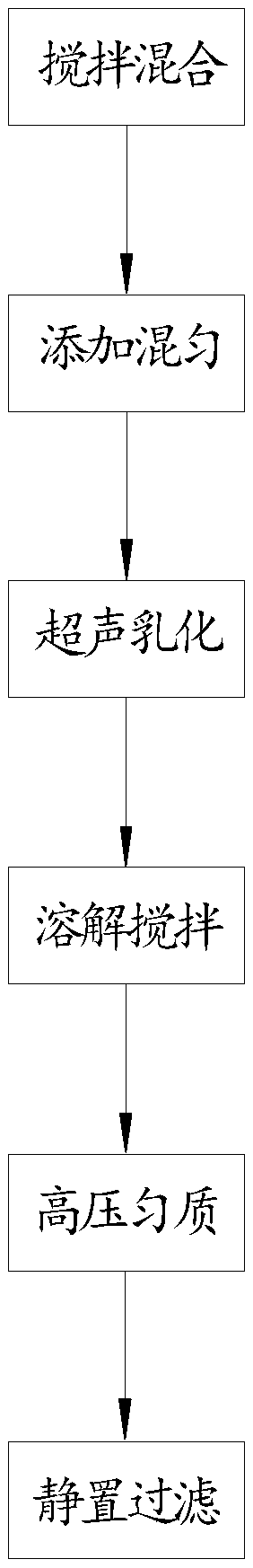

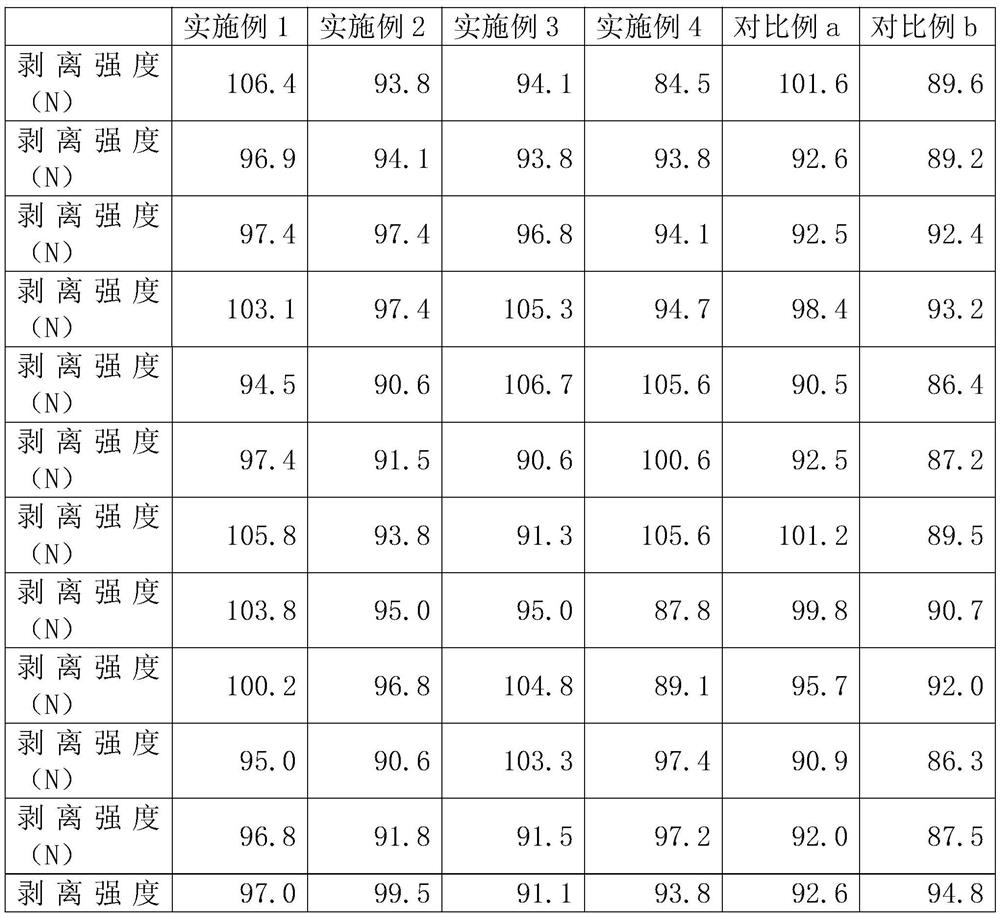

Lemon-flavored emulsifying essence and preparation process thereof

PendingCN110754598AImprove dispersion uniformityReduce the chance of delaminationClimate change adaptationFood preservationChitinAnoxomer

The invention discloses a lemon-flavored emulsifying essence and a preparation process thereof. Productive raw materials of the emulsifying essence comprises a lemon-flavored essence, a weighting agent, an antioxidant, an emulsifying agent, deionized water, thickening agent and a compound preservative. The lemon-flavored essence comprises lemon oil, white lemon oil, natural linalool, natural capraldehyde, Sunkist sweet orange oil, geranium oil, natural terpineol and salad oil. A production process comprises the following steps: performing stirring and mixing; performing addition and uniform mixing; performing ultrasonic emulsification; performing dissolution and stirring; performing high-pressure homogenization; and performing standing and filtration. According to the emulsifying essence disclosed by the invention, primary emulsifying solutions are homogenized, so that the dispersion uniformity of the essence emulsifying solutions is further improved, and the layering probability of the emulsified essence is reduced; the compound preservative formed by compounding sodium dehydroacetate, chitosan and tea polyphenols is added into the emulsifying solutions, so that the corrosion resistant performance of the emulsified essence is effectively promoted, and the effects of extending the storage time and prolonging the service life of the emulsified essence can be achieved.

Owner:翟文娟

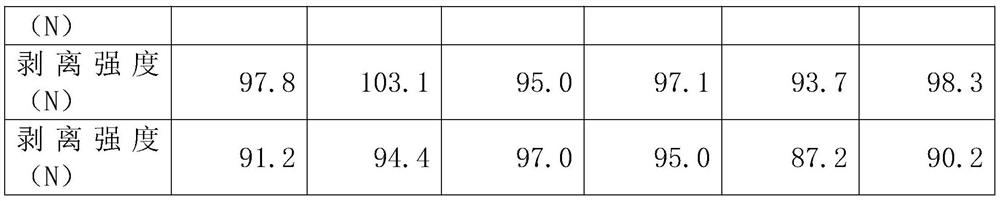

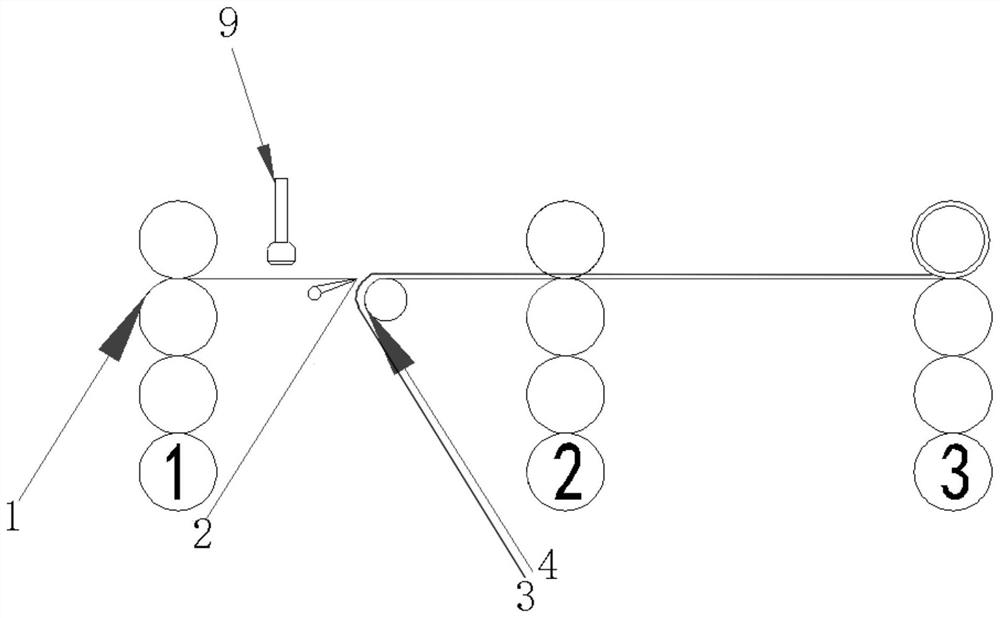

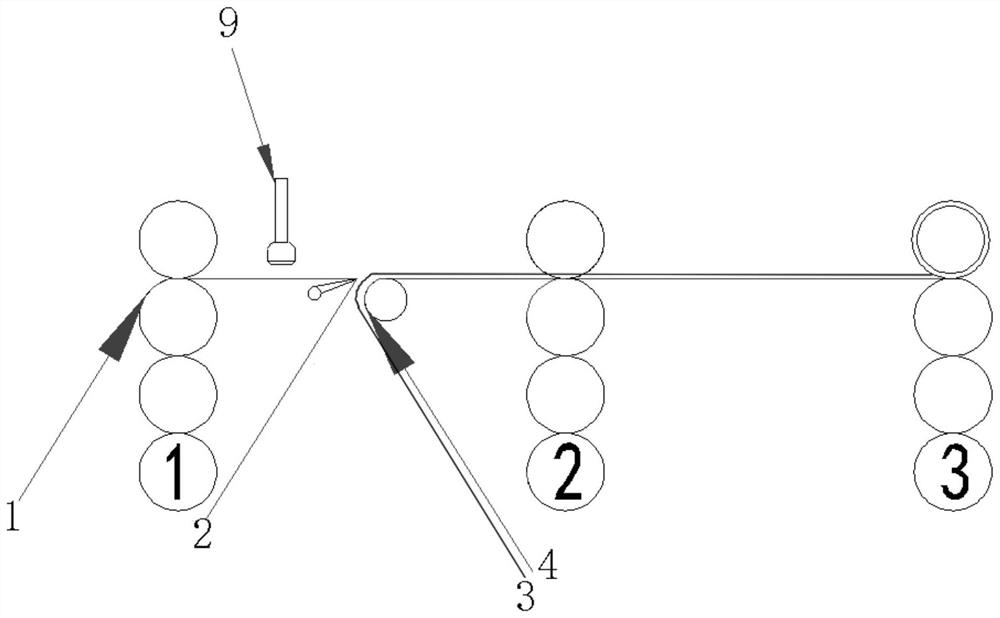

Modified regenerated PVB composite laminated fabric and preparation method thereof

PendingCN112895639AReduce processing costsSolve processing problemsSynthetic resin layered productsEpoxy resin adhesivesPolymer sciencePlasticizer

The invention provides a modified regenerated PVB composite laminated fabric and a preparation method thereof; the fabric comprises a fabric layer and at least one PVB composite layer; a bonding layer is arranged between the fabric layer and the PVB composite layer; the modified regenerated PVB composite laminated fabric is characterized in that the PVB content in the PVB composite layer is at least 40%; the bonding layer is composed of epoxy compounds; and the fabric layer is composed of natural fibers, artificial fibers or a combination of the natural fibers and the artificial fibers; and in addition, additive components such as inorganic filler, a plasticizer, an antioxidant, an anti-ultraviolet agent and a slipping agent can be added into the PVB composite layer of the fabric, so that the performance of the PVB composite layer is improved. When the fabric is prepared, the raw materials of the PVB composite layer are mixed and prepared into a film, and then the PVB film and the fabric layer coated with a binder are bonded and formed under the action of a roller press.

Owner:YONGSHENG HAEIL DIFFERENTIAL FABRIC

Attapulgite mixing agent and preparation method thereof

InactiveCN110791135AImprove filling abilityImprove performanceAntifouling/underwater paintsPaints with biocidesMasterbatchMicroorganism

The invention discloses an attapulgite mixing agent and a preparation method thereof, and belongs to the technical field of auxiliary materials. The attapulgite mixing agent comprises the following materials: 10-12 parts of resin, 32-42 parts of foundation soil, 15-20 parts of organic montmorillonite, 5-10 parts of inorganic material powder, and 4-6 parts of a synergist. According to the attapulgite mixing agent and the preparation method thereof, the purpose of self-reinforcing and toughening of the mixing agent is effectively achieved; a synergist and a stabilizer are utilized; on the premise of ensuring stability, the emulsifier and the expanded graphite are matched to achieve effective thickening effect so that paint film is plump, the probability of sedimentation and layering is reduced, and pin hole filling performance is good. Resin is added during preparation and directly matched with color masterbatch to form powder, the effects of increasing the color and improving the adhesive force can be achieved in the matching process of paint vehicles with different color values, the chemical inertness of attapulgite is matched, the effective chemical resistance is achieved, the growth of microorganisms is inhibited, and the environmental protection property is high.

Owner:安徽省安邦矿物股份有限公司

Process for solving problem of layering during graphene processing

ActiveCN111941533ASmall peeling forceAvoid Product LayeringCarbon compoundsMetal working apparatusEngineeringDie cutting

The invention provides a process for solving the problem of layering during graphene processing. According to the process, the layering rate of a die-cut product is decreased, and the quality of the product is ensured. According to the process, a self-contained film of graphene is stripped in advance before die cutting, then a release film with a double-sided adhesive layer is composited on the back surface of the graphene, the upper surface of the double-sided adhesive layer is bonded to the back surface of the graphene, and then the graphene bonded with the release film through the double-sided adhesive layer is cut off through a cutting die; and a gap area between every two adjacent sets of products of different sheets is cut into a filling middle area through the cutting die, and the filling middle areas are not connected with the adjacent products away from the filling middle areas.

Owner:SUZHOU ANJIE TECH

Polycrystalline cubic boron nitride composite sheet and preparation method thereof

PendingCN113751711AReduce metal contentImprove thermal stabilityTurbinesOther manufacturing equipments/toolsThermal dilatationCrack resistance

The invention provides a polycrystalline cubic boron nitride composite sheet and a preparation method thereof. According to the polycrystalline cubic boron nitride composite sheet and the preparation method thereof, used titanium-transition metal solid solution boride ceramic has the advantages of high melting point, high hardness, excellent corrosion resistance and oxidation resistance, good electrical conductivity and thermal conductivity, and a thermal expansion coefficient similar to that of cubic boron nitride, the titanium-transition metal solid solution boride ceramic does not contain metal, so that a large amount of metal cannot permeate into the cubic boron nitride layer under high-temperature and high-pressure conditions, meanwhile, a chemical reaction can occur at an interface of a mixed initial material of a titanium-tungsten boride ceramic substrate and the cubic boron nitride layer under the high-temperature and high-pressure conditions to form chemical bond combination, and the composite sheet has the characteristics of good thermal stability, difficulty in layering, good crack resistance, good collapse resistance and the like.

Owner:河南领科材料有限公司

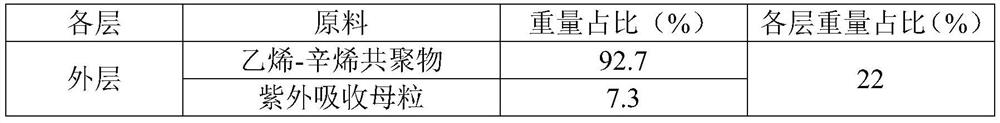

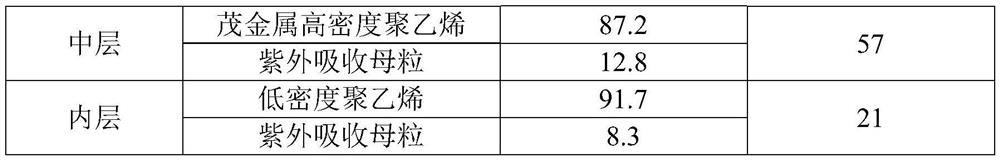

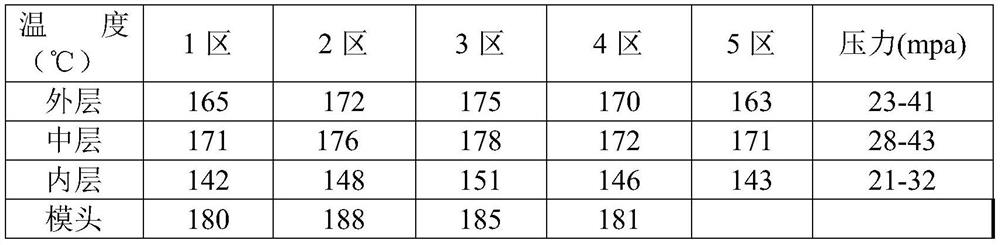

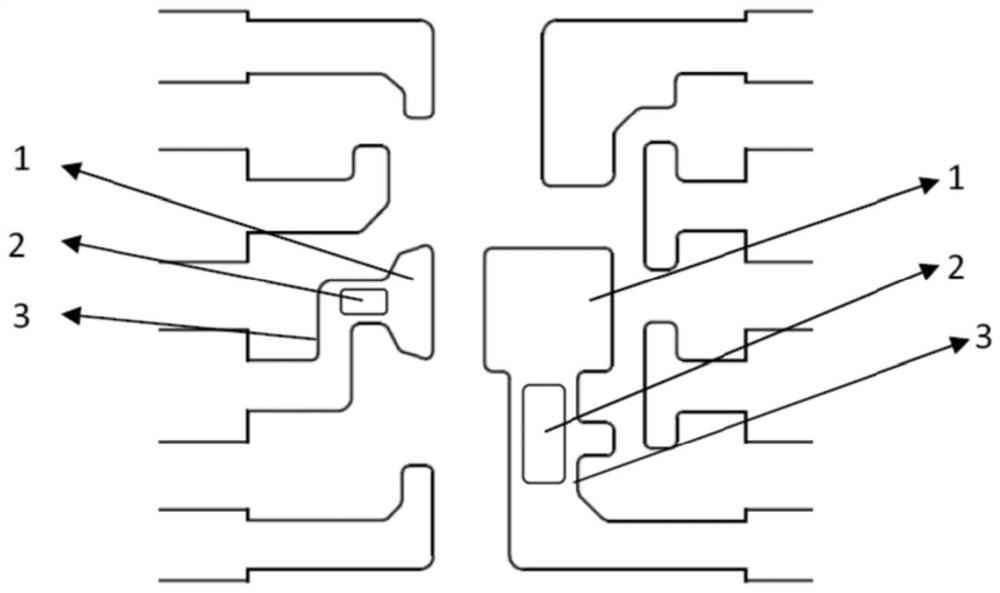

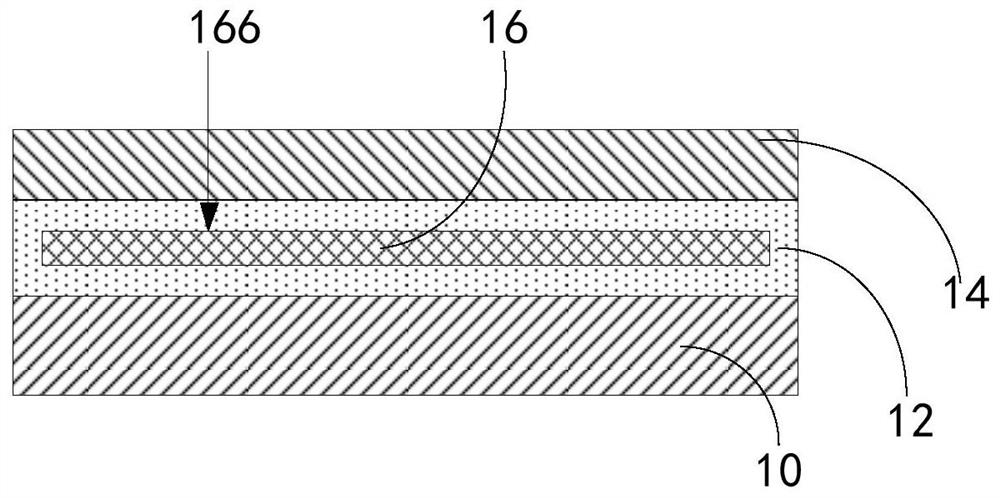

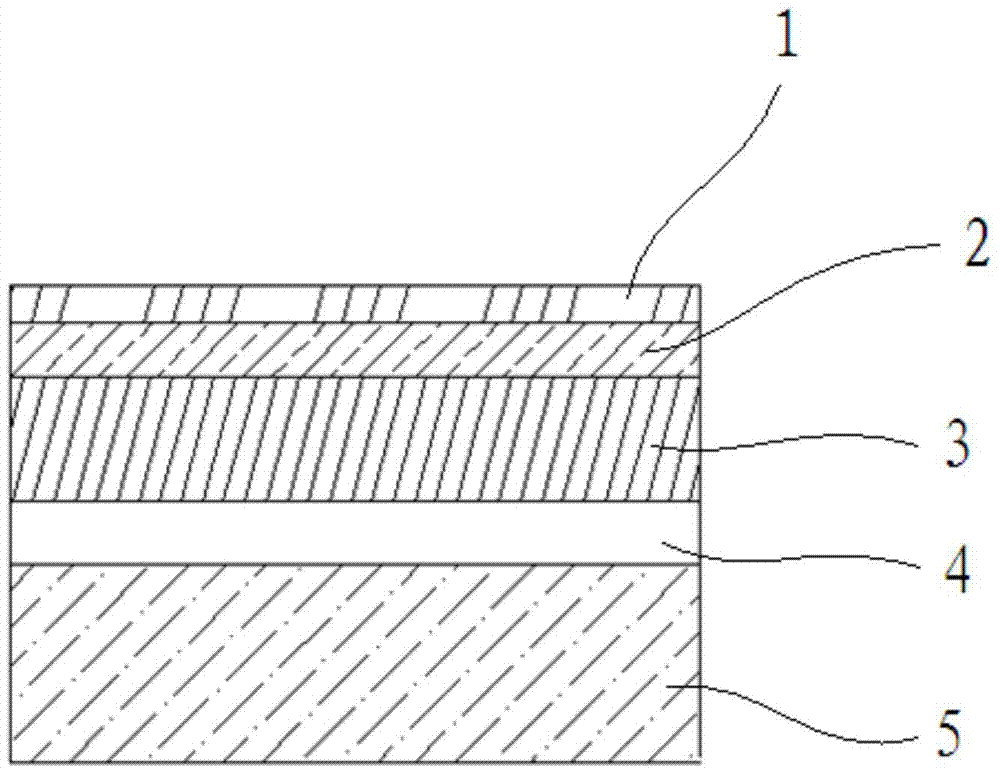

A solar cell backsheet film with high composite fastness

ActiveCN110948977BReduce the chance of delaminationAdhesivelySynthetic resin layered productsElectrical equipmentPolyolefinPhysical chemistry

The invention relates to a solar cell backboard film, which is composed of outer layer, middle layer and inner layer materials. The material of the outer layer is olefin copolymer, the material of the middle layer is metallocene polyolefin, and the material of the inner layer is polyolefin. Wherein the outer layer of the solar cell back sheet, between the middle layer and the inner layer material, between the inner layer material and the EVA layer of the solar cell back sheet, and between the outer layer material and the middle layer PET of the solar cell back sheet due to the synergistic effect. It has tight composite fastness, which minimizes the chance of delamination of solar cell backsheets. Moreover, the materials of the outer layer, the middle layer and the inner layer of the solar battery backplane film have strong intermolecular forces among each other, thereby improving the water resistance and water vapor corrosion resistance of the solar battery backplane film.

Owner:JIANGMEN PENGJIANG HUALONG PACKING MATERIAL

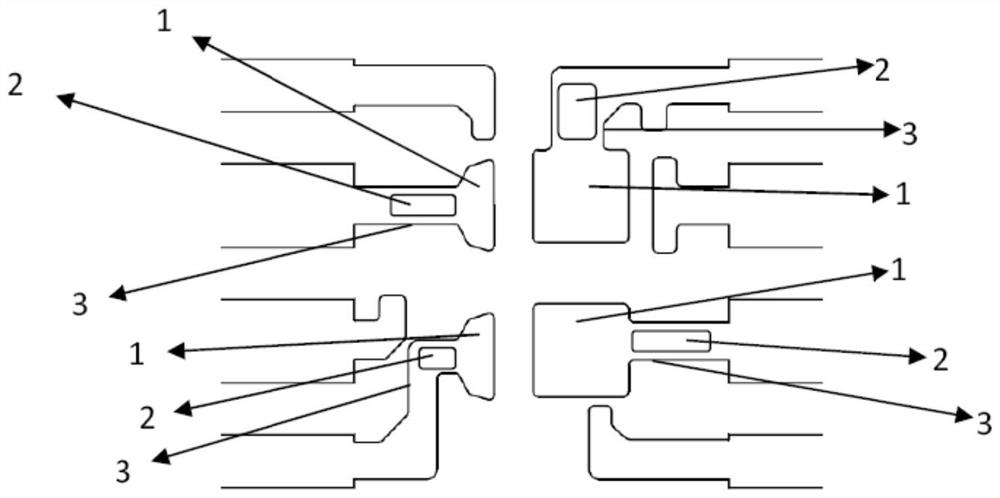

Lead frame suitable for coplanar plastic package optocoupler packaging

PendingCN114551392ADoes not affect bond qualityReduce typesSemiconductor/solid-state device detailsSolid-state devicesLight guideManufactured material

A substrate of the lead frame comprises a plurality of substrates, a flow suppression hole is formed in a substrate epitaxial region of each substrate, and the distance from the edge of the outermost side of the flow suppression hole to the edge of the substrate epitaxial region is 0.2 mm-0. 5 mm. The flow suppression holes are formed in the epitaxial area of the lead frame substrate, diffusion of the light guide glue is controlled through surface tension of the light guide glue under the condition that box dam glue is not used in the light guide glue dispensing process, the radian of the light guide glue is prevented from being reduced, the complexity of raw materials in a packaging body is reduced, the reliability of components is improved, box dam materials are omitted, and the production cost is reduced. And the cost is reduced.

Owner:XIAN MICROELECTRONICS TECH INST

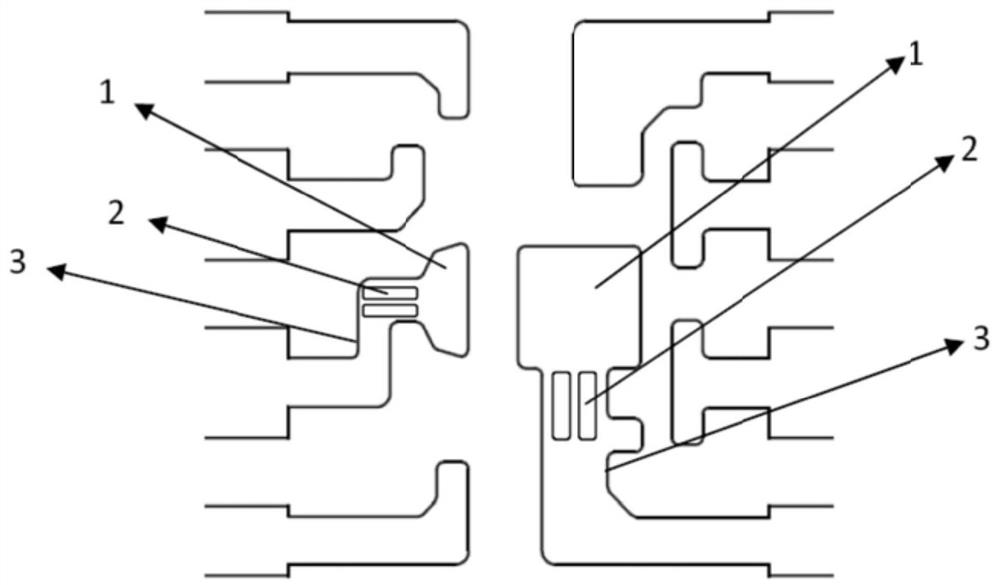

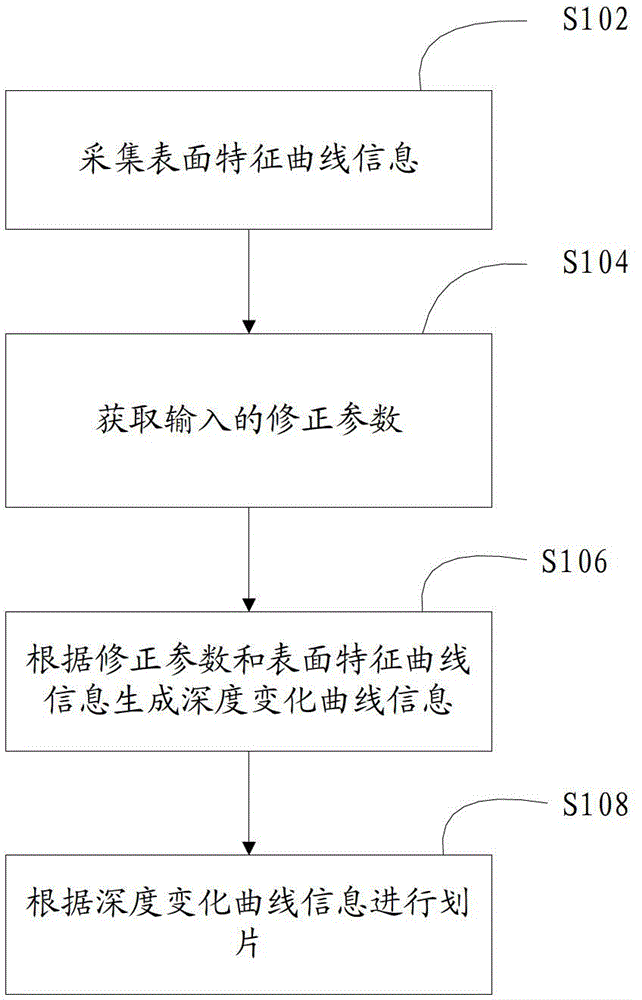

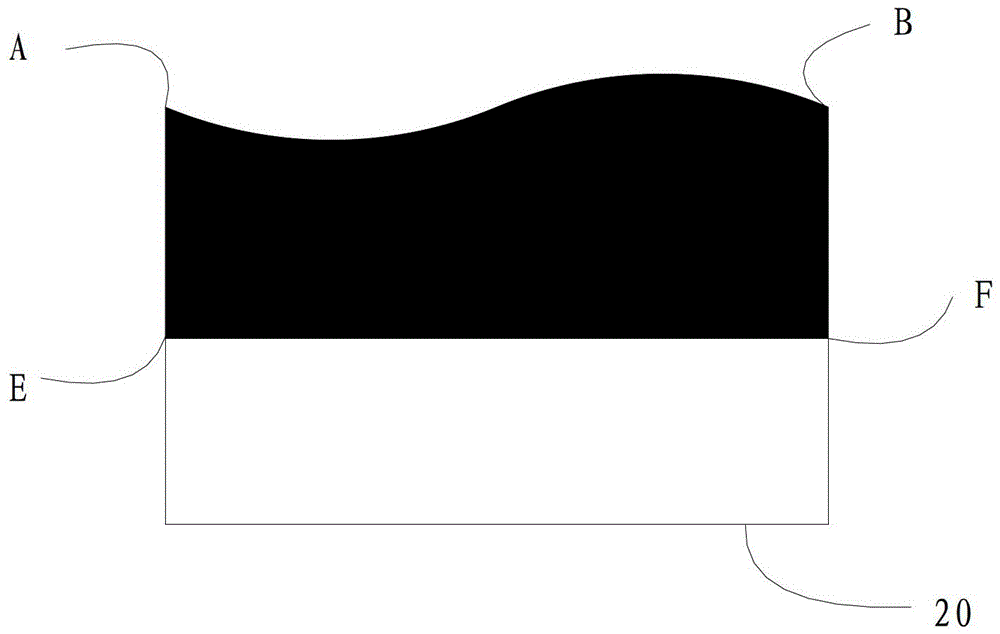

Scribing method and scribing device

Owner:HANS LASER TECH IND GRP CO LTD

Display panel capable of being bent in solid state and display device

ActiveCN111968504AReduce bending stressReduce the chance of delaminationIdentification meansPhysicsSolid-state

The invention discloses a display panel capable of being bent in a solid state and a display device. The display panel comprises a first functional layer, an adhesive layer and a second functional layer which are arranged in a stacked mode, and a hollow deformable part which is located in the adhesive layer and communicated with the adhesive layer, and a flowable medium is arranged in the deformable part. In this way, the probability of layering between the adhesive layer and the adjacent functional layers can be reduced.

Owner:HEFEI VISIONOX TECH CO LTD

Manufacturing method of rigid-flexible printed circuit board with multi-step buried blind holes

InactiveCN110958789AReduce explosion rateReduce the chance of delaminationConductive pattern polishing/cleaningMultilayer circuit manufacturePunchingPrinted circuit board

The invention discloses a manufacturing method of a rigid-flex printed circuit board with multi-step buried blind holes. The manufacturing method comprises the steps of manufacturing of an inner-layercopper flexible board, manufacturing of a middle-layer copper flexible board and manufacturing of an outer-layer copper flexible board. The manufacturing method of the inner-layer copper soft board comprises the steps of preprocessing, copper deposition, copper plating, post-processing, CVL pasting, pressing, baking and lamination waiting. The manufacturing method of the middle-layer copper softboard comprises the following steps: preprocessing, laminating with an inner-layer copper soft board to be laminated, laminating, punching, milling blind holes, removing glue slag, depositing copper,plating copper, post-processing, roughening and laminating. The manufacturing method of the outer-layer copper soft board comprises the steps of preprocessing, lamination with a middle-layer copper soft board to be laminated, lamination, punching, blind hole milling, glue residue removal, hole metallization, copper plating and post-processing. The multiple layers of copper soft boards in the rigid-flexible combined board are divided into three groups according to the inner part, the middle part and the outer part, and the rigid-flexible combined board with the multi-step buried blind holes ismanufactured through processing and laminating respectively. The processing efficiency is high, and the plate explosion rate and the layering rate of the laminated final product are low.

Owner:江苏弘信华印电路科技有限公司

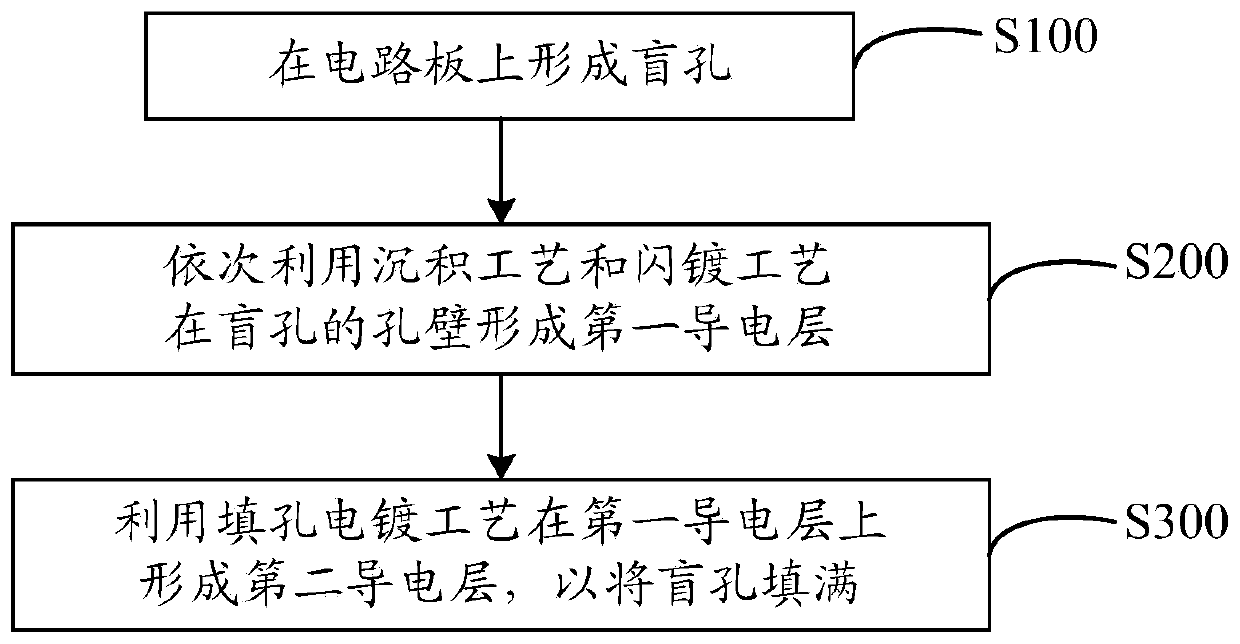

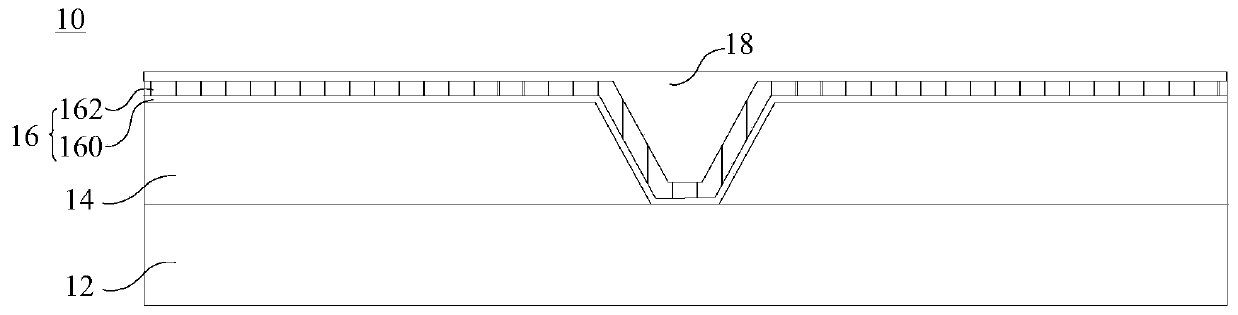

Circuit board hole filling method and circuit board

ActiveCN111447758AReduce breakageReduce the chance of delaminationConductive pattern reinforcementPrinted element electric connection formationDeposition processPhysics

The invention discloses a circuit board hole filling method and a circuit board. The circuit board hole filling method comprises the steps of forming blind holes in the circuit board; forming a firstconductive layer on the hole wall of the blind hole by using a deposition process and a flash plating process in sequence, wherein the volume of the blind hole is greater than that of the first conductive layer; and forming a second conductive layer on the first conductive layer by using a hole filling electroplating process to fill the blind hole, wherein the hole filling electroplating process comprises a pre-plating process and an electroplating process which are carried out in sequence, the current density of the pre-plating process is smaller than the current density of the electroplatingprocess, and the time of the pre-plating process is less than the time of the electroplating process. By means of the mode, the bonding force between the first conductive layer and the second conductive layer can be improved, the probability that the first conductive layer and the second conductive layer are broken and layered when a thermo-mechanical load is large is reduced, and then the reliability of the circuit board is improved.

Owner:SHENNAN CIRCUITS

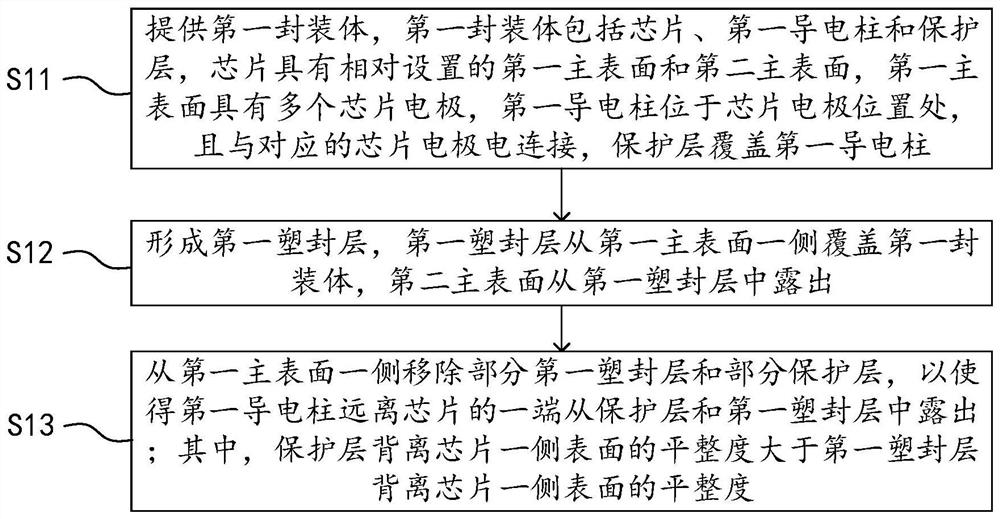

Semiconductor packaging device and preparation method thereof

PendingCN114597134AImprove reliabilityImprove bindingSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingSemiconductor package

The invention discloses a semiconductor packaging device and a preparation method thereof, and belongs to the technical field of semiconductor packaging. The preparation method comprises the steps that a first packaging body is provided, the first packaging body comprises a chip, first conductive columns and a protection layer, the chip is provided with a first main surface and a second main surface which are oppositely arranged, the first main surface is provided with a plurality of chip electrodes, the first conductive columns are located at the positions of the chip electrodes and electrically connected with the corresponding chip electrodes, and the protection layer is arranged on the first conductive columns; the protective layer covers the first conductive column; forming a first plastic packaging layer which covers the first packaging body from one side of the first main surface, and exposing the second main surface from the first plastic packaging layer; removing part of the first plastic package layer and part of the protective layer from one side of the first main surface, so that one end, far away from the chip, of the first conductive column is exposed from the protective layer and the first plastic package layer; and the flatness of the surface of one side of the protective layer deviating from the chip is greater than that of the surface of one side of the first plastic packaging layer deviating from the chip. The reliability of the semiconductor packaging device can be improved.

Owner:NANTONG TONGFU MICROELECTRONICS CO LTD

Construction method and structure of antiskid surface of pavement

InactiveCN113089409AImprove support strengthImprove stabilityPaving reinforcementsIn situ pavingsStructural engineeringRoad surface

The invention discloses a construction method and structure of an antiskid surface of a pavement and belongs to the technical field of construction of the antiskid surface of the pavement. The structure comprises drainage layers laid on the two sides of the pavement, an upper surface layer, a middle surface layer and a lower surface layer are sequentially laid between the drainage layers on the two sides from top to bottom, and an antiskid surface layer located above the drainage layers is laid on the upper surface layer. The preparation method of the antiskid layer comprises the following steps of: S1, heating asphalt to 90-110 DEG C for softening the asphalt; S2, stirring and mixing limestone and diabase to form a mixture, and heating the mixture to 175-185 DEG C; and S3, stirring the softened asphalt and the mixture for 5-10 minutes to form the antiskid surface layer. The structure is simple in structure, forms the antiskid surface on the pavement, enhances the antiskid capacity of the pavement, and improves the strength of the pavement.

Owner:贵州省安顺公路管理局 +1

Solid-state bendable display panel and display device

ActiveCN111968504BReduce the chance of delaminationImprove yieldIdentification meansDisplay deviceEngineering

Owner:HEFEI VISIONOX TECH CO LTD

Multi-component silane coupling agent modified phenolic resin-based composite disc brake pad and preparation method thereof

Owner:SHANDONG GOLD PHOENIX

Variable frequency low speed mixer and method for mixing materials with different stacking densities

ActiveCN101905131BAvoid uneven mixingReduce the chance of delaminationMixing methodsMixersLow speedMixed materials

The invention provides a variable frequency low speed mixer and a method for mixing materials with different stacking densities. The mixer comprises a main mixing chamber and an auxiliary mixing chamber, wherein the auxiliary mixing chamber is arranged in the main mixing chamber; a material mixing cover of the main mixing chamber is provided with a granular material feed port; the bottom of the main mixing chamber is provided with an impeller mechanism; the top of the auxiliary mixing chamber is provided with a powdery material feed port and a liquid material feed port; the wall of the auxiliary mixing chamber is provided with a liquid material discharge port and a plurality of powdery material discharge ports; the top of the auxiliary mixing chamber is provided with a liquid material temporary storage chamber which is communicated with the liquid material feed port and the liquid material discharge port; and by the method, the granular material or preliminarily mixed material is threw up by using the main mixing chamber and the powdery material or the liquid material is scattered in the main mixing chamber by using the auxiliary mixing chamber, so various materials with large stacking density difference are mixed uniformly. The mixer and the method can effectively prevent the phenomenon of non-uniform mixing of the materials, realize premixing with good effect and reduce the probability of demixing of the granular material and the powdery material while greatly shortening the mixing time.

Owner:合诚技术股份有限公司

Hot air fusion welding method for circuit board disassembly to reduce chip delamination rate

InactiveCN109822174BReduce the chance of delaminationImprove reusabilityHeating appliancesPrinted circuitsThermodynamicsEconomic benefits

The invention discloses a circuit board dismantling hot air fusion welding method for reducing chip delamination rate, comprising: sequentially dismantling the circuit board in the first heating chamber, the second heating chamber, the third heating chamber, the fourth heating chamber, The heating chamber and the fifth heating chamber are welded, wherein the temperature of the first heating chamber is 270-300 degrees Celsius, the temperature of the second heating chamber is 250-290 degrees Celsius, and the temperature of the third heating chamber is 270-300 degrees Celsius. The temperature of the chamber is 230-240 degrees Celsius, the temperature of the fourth heating chamber is 240-250 degrees Celsius, and the temperature of the fifth heating chamber is 230-240 degrees Celsius. By adopting the method, the delamination rate of the chip can be significantly reduced under the premise of ensuring that the circuit board is fully welded, thereby improving the reusability of the chip and having high economic benefits.

Owner:TSINGHUA UNIV

High-strength rainbow film and preparation method thereof

InactiveCN114834121AHomogeneous miscibilityHigh strengthSynthetic resin layered productsFlat articlesPolymer sciencePolystyrene

The invention discloses a high-strength rainbow film and a preparation method thereof, and belongs to the technical field of thin films, the high-strength rainbow film comprises a plurality of A layers, B layers and C layers which are arranged by combining ACBCACB... A. The A layers comprise polystyrene resin, the B layers comprise polypropylene resin, the C layers comprise a copolymer mixture of polypropylene and polystyrene, and the copolymer mixture of the polypropylene resin and the polystyrene resin is a copolymer mixture of the polypropylene resin and the polystyrene resin. The copolymer mixture of polypropylene and polystyrene is formed by mixing polystyrene powder and modified polypropylene, and the modified polypropylene is obtained by grafting styrene on a polypropylene molecular chain through an initiator. According to the high-strength rainbow film and the preparation method thereof disclosed by the invention, the copolymer mixture of polypropylene and polystyrene has good compatibility with polypropylene and polystyrene at the same time, so that connection among the layer C, the layer A and the layer B can be increased, the layering probability of the rainbow film is reduced, stress transfer between layers is increased, and the tensile strength of the rainbow film is improved. The overall strength of the rainbow film is improved.

Owner:晋江鑫泰塑料有限公司

A process for solving the delamination problem during graphene processing

ActiveCN111941533BSmall peeling forceAvoid layeringCarbon compoundsMetal working apparatusEngineeringGraphite

Owner:SUZHOU ANJIE TECH

Manufacturing method of aluminum foil parafilm

ActiveCN105129221BHigh composite strengthReduce the chance of delaminationLamination ancillary operationsBio-packagingComposite filmAluminum foil

Owner:ZHEJIANG GOLDSTONE PACKING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com