Manufacturing method of aluminum foil parafilm

A manufacturing method and sealing film technology, applied in chemical instruments and methods, sustainable manufacturing/processing, sealing, etc., can solve problems such as insufficient adhesive reaction time, long delivery period, weak composite strength, etc., to reduce time , shorten the delivery time, reduce the effect of delamination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

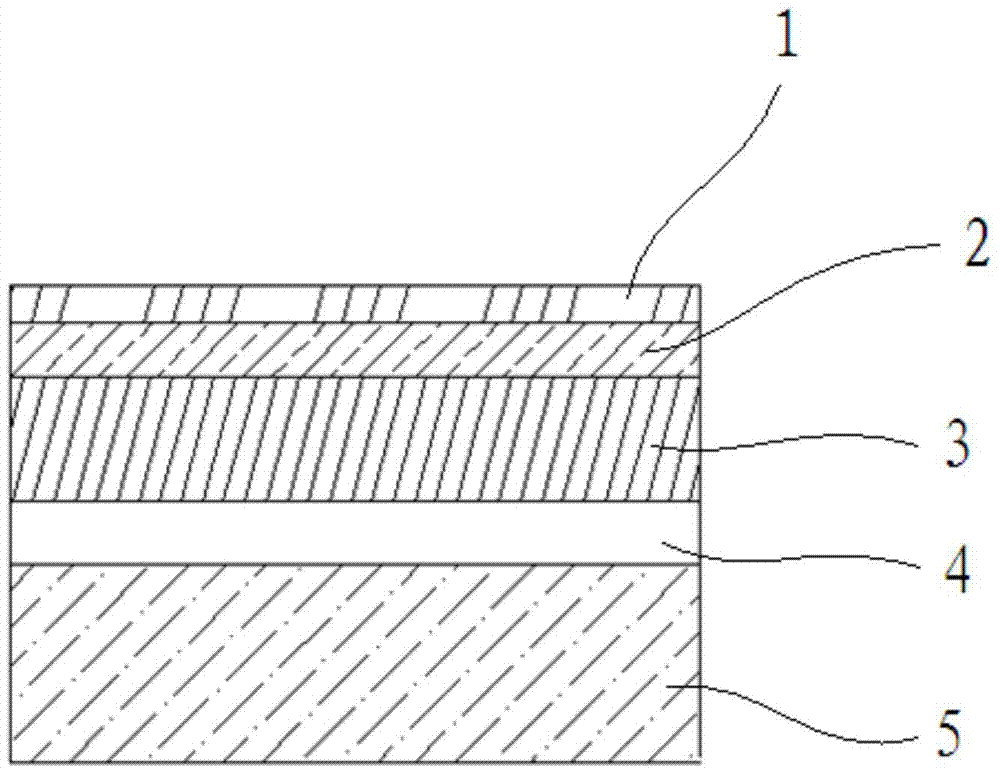

[0032] refer to figure 2 , an aluminum foil sealing film, which is suitable for sealing bottles with the same material as the inner film, and can be cooked under high temperature conditions. From outside to inside, it includes: varnish layer 1, ink layer 2, aluminum foil layer 3, adhesive mixture layer 4 and a thermoplastic resin film. Wherein the thermoplastic resin film is an inner film.

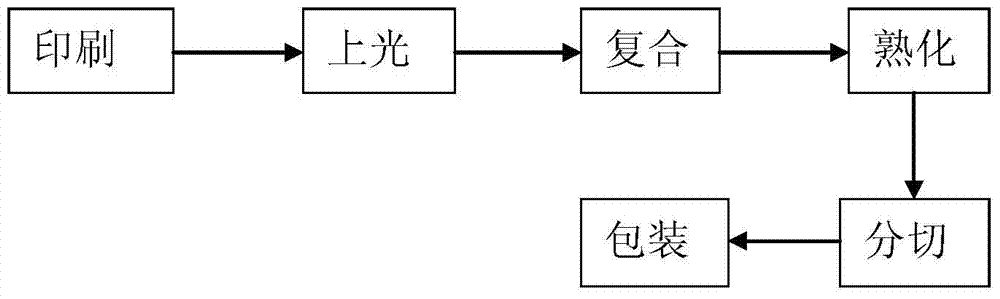

[0033] refer to image 3 , a kind of manufacture method of above-mentioned aluminum foil sealing film of the present invention: comprise successively

[0034] In the composite process, one side of the aluminum foil is coated with an adhesive, and after drying, the thermoplastic resin film is thermally laminated on the side of the aluminum foil coated with the adhesive to form a composite film;

[0035] In the first curing process, the composite film is placed in a curing chamber for curing;

[0036] Warehouse, put the cured composite film into the inventory;

[0037] In the printing ...

Embodiment 2

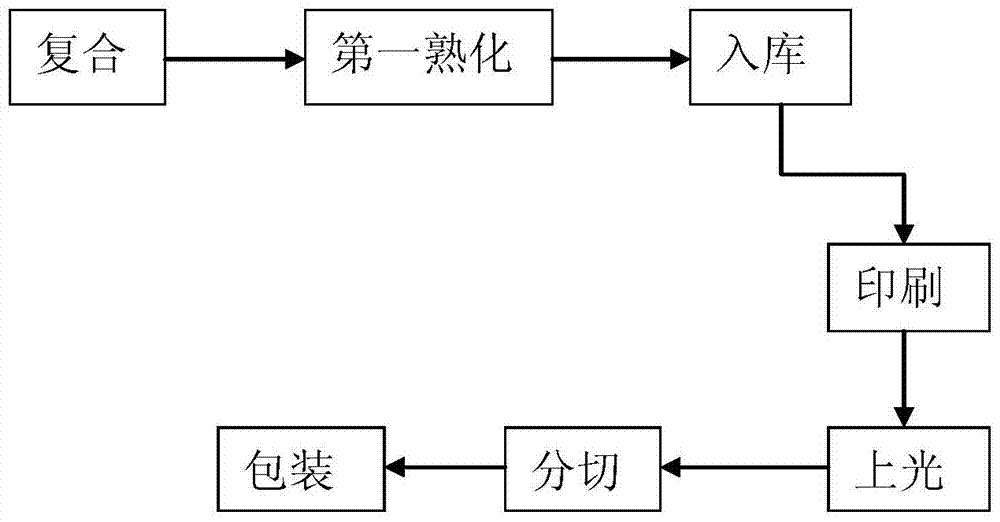

[0052] refer to Figure 4 , the present embodiment provides a method for manufacturing an aluminum foil parafilm in embodiment 1, which is substantially the same as in embodiment 1, except that:

[0053] There is also a second aging process between the glazing process and the cutting process. The second curing process makes the main agent and auxiliary agent of the varnish coated on the surface of the aluminum foil fully react in the glazing process, and then the bonding effect between the varnish and the aluminum foil is better, and the varnish can effectively protect the aluminum foil from It is oxidized by the outside air, prolonging the service life of the aluminum foil sealing film. At the same time, the second aging process can further promote the full reaction of the main agent of the adhesive in the composite film and the curing agent, so that the obtained aluminum foil sealing film has better composite strength.

[0054] In the second curing process, the temperature...

Embodiment 3

[0056] This embodiment provides a method for manufacturing an aluminum foil sealing film in Embodiment 1, which is substantially the same as Embodiment 2, except that:

[0057] In the compounding process, the hot-pressing temperature of the thermoplastic resin film and the aluminum foil is 60°C; the speed of the thermoplastic resin film and the aluminum foil is 150 m / min; the glue amount of the adhesive is 5.0 grams per square meter .

[0058] In the composite process, the specific method of drying treatment, this example adopts the method of passing the aluminum foil coated with adhesive on one side at a speed of 180 m / min without stopping in sequence at 65°C, 80°C, and 85°C in three-stage ovens , for drying and drying treatment.

[0059] In the first curing process, the temperature of the curing chamber is 60° C., and the curing time is 150 hours.

[0060] In the printing process, the drying temperature for drying the ink after printing is 60°C; the speed for drying the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com