Lemon-flavored emulsifying essence and preparation process thereof

The technology of emulsified essence and preparation process is applied in the field of lemon-flavored emulsified essence and its preparation, which can solve the problems of difficult long-term storage, easy stratification, uneven emulsified essence emulsion, etc., so as to reduce the probability of stratification, improve the dispersion uniformity, The effect of improving the storage time and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

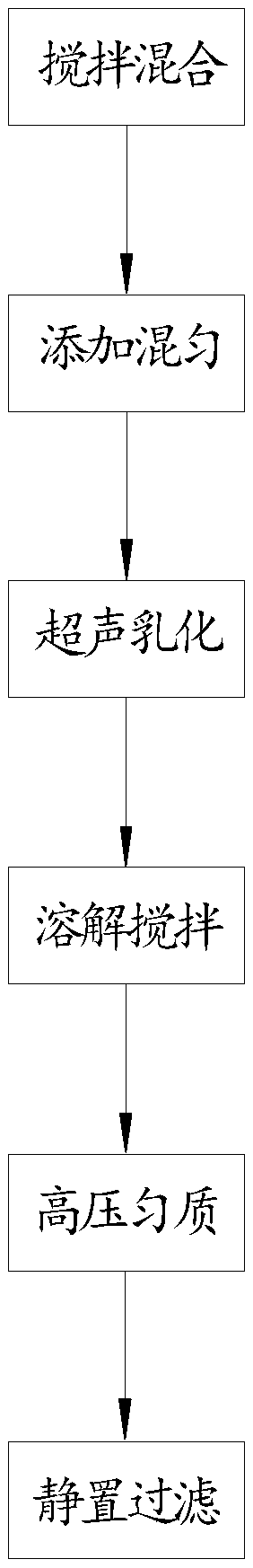

[0062] S1, stirring and mixing: select 4 kg of lemon oil, 4 kg of white lemon oil, 2.8 kg of natural linalool, 2.8 kg of decanal, 2.8 kg of Sunkist sweet orange oil, 2.8 kg of geranium oil, 2.8 kg of natural terpineol and 8 kg Kilogram of salad oil is fully stirred and mixed to make lemon flavor essence;

[0063] S2, adding and mixing: add 5 kg of weighting agent and 5 kg of antioxidant to the lemon-flavored essence that has been stirred and mixed in S1 and stir for 10 minutes to obtain a lemon-flavored oil-soluble essence emulsion;

[0064] S3. Ultrasonic emulsification: The oil-soluble essence emulsion prepared in S2 is subjected to cyclic ultrasonic emulsification for 100 minutes to obtain an emulsified essence oil phase;

[0065] S4. Dissolving and stirring: select 40 kg of deionized water, 10 kg of emulsifier, 5 kg of thickener, and 3 kg of compound preservative, dissolve the emulsifier, thickener, and compound preservative in deionized water at room temperature, and set ...

Embodiment 2

[0069] S1, stirring and mixing: choose 5 kilograms of lemon oil, 5 kilograms of lime oil, 2 kilograms of natural linalool, 2 kilograms of decanal, 2 kilograms of Sunkist sweet orange oil, 2 kilograms of geranium oil, 2 kilograms of natural terpineol and 12 Kilogram of salad oil is fully stirred and mixed to make lemon flavor essence;

[0070] S2, adding and mixing: add 7 kg of weighting agent and 8 kg of antioxidant to the lemon-flavored essence that has been stirred and mixed in S1 and stir for 10 minutes to obtain a lemon-flavored oil-soluble essence emulsion;

[0071] S3. Ultrasonic emulsification: The oil-soluble essence emulsion prepared in S2 is subjected to cyclic ultrasonic emulsification for 100 minutes to obtain an emulsified essence oil phase;

[0072] S4. Dissolving and stirring: select 40 kg of deionized water, 8 kg of emulsifier, 3 kg of thickener, and 2 kg of compound preservative, dissolve the emulsifier, thickener, and compound preservative in deionized water ...

Embodiment 3

[0076] S1, stirring and mixing: choose 4 kilograms of lemon oil, 4 kilograms of white lemon oil, 2.5 kilograms of natural linalool, 2.5 kilograms of decanal, 2.5 kilograms of Sunkist sweet orange oil, 2.5 kilograms of geranium oil, 2 kilograms of natural terpineol and 12 Kilogram of salad oil is fully stirred and mixed to make lemon flavor essence;

[0077] S2, adding and mixing: add 7 kg of weighting agent and 8 kg of antioxidant to the lemon-flavored essence that has been stirred and mixed in S1 and stir for 10 minutes to obtain a lemon-flavored oil-soluble essence emulsion;

[0078] S3. Ultrasonic emulsification: The oil-soluble essence emulsion prepared in S2 is subjected to cyclic ultrasonic emulsification for 100 minutes to obtain an emulsified essence oil phase;

[0079] S4. Dissolving and stirring: select 40 kg of deionized water, 9 kg of emulsifier, 4 kg of thickener, and 2 kg of compound preservative, dissolve the emulsifier, thickener, and compound preservative in d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com