A solar cell backsheet film with high composite fastness

A technology for solar cells and backsheet films, applied in circuits, photovoltaic power generation, household appliances, etc., can solve the problems of large water vapor transmission, corrosion, poor weather resistance, etc., to reduce the probability of delamination, improve the barrier to water vapor, The effect of improving compound fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

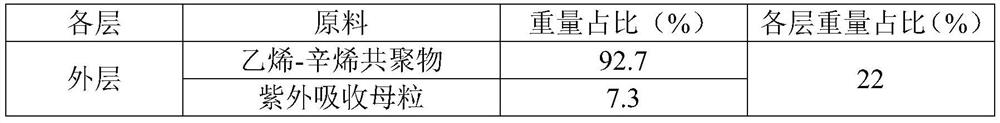

[0027] A solar backplane film is composed of outer layer, middle layer and inner layer materials, and the components of each layer are as follows.

[0028] Table 1 Example 1 The proportion of components in each layer

[0029]

[0030]

[0031] Among them, the melt index of the outer material ethylene-octene copolymer is 2g / 10min, and the density is 0.810g / cm 3 ; The melt index of the middle material metallocene high-density polyethylene is 0.05 / 10min, and the density is 0.900g / cm 3 ;The melt index of the inner material low-density polyethylene is 2g / 10min, and the density is 0.900g / cm 3 .

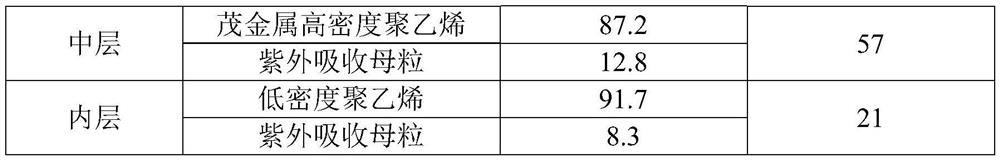

[0032] The preparation method of above-mentioned solar back plate film is as follows:

[0033] 1. Put the raw materials of each layer into the outer layer extruder, middle layer extruder, and inner layer extruder respectively for melting and plasticizing, and then output them. The materials output by each extruder are transported to the die head, extruded and blown film and Fusion...

Embodiment 2

[0048] A solar backplane film is composed of outer layer, middle layer and inner layer materials, and the components of each layer are as follows.

[0049] Table 3 embodiment 2 each layer component ratio

[0050]

[0051] The preparation method of the above-mentioned solar backboard film is the same as that in Example 1.

[0052] Among them, the melt index of the outer material propylene-octene copolymer is 7g / 10min, and the density is 0.895g / cm 3 ; The melt index of the middle material metallocene high-density polystyrene is 6g / 10min, and the density is 0.970g / cm 3 ;The melt index of the inner low-density polypropylene is 15g / 10min, and the density is 0.940g / cm 3 .

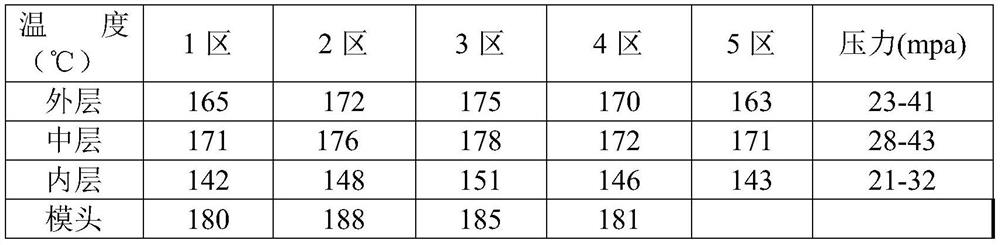

[0053] The setting process of extruder process parameter is similar to embodiment 1, and concrete process parameter is as shown in the following table:

[0054] Extruder in table 4 embodiment 2 is for each layer component preparation parameter

[0055]

Embodiment 3

[0057] A solar backplane film is composed of outer layer, middle layer and inner layer materials, and the components of each layer are as follows.

[0058] Table 5 embodiment 3 each layer component ratio

[0059]

[0060]

[0061] The preparation method of the above-mentioned solar backboard film is the same as that in Example 1.

[0062] Among them, the melt index of the outer material ethylene-butene copolymer is 3.5 / 10min, and the density is 0.882 / cm 3 ; The melt index of the middle layer material metallocene polypropylene is 2.3g / 10min, and the density is 0.900g / cm 3 ;The melt index of the inner material polyhexene is 7g / 10min, and the density is 0.900g / cm 3 .

[0063] The setting process of extruder process parameter is similar to embodiment 1, and process parameter is as shown in the table below:

[0064] Extruder in table 6 embodiment 3 is for each layer component preparation parameter

[0065]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com