Scribing method and scribing device

A technology for scribing and scratching depth, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve problems such as increased production costs, increased defective rate, edge collapse, etc., to reduce production costs and reduce defective products rate, reduce the effect of chipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

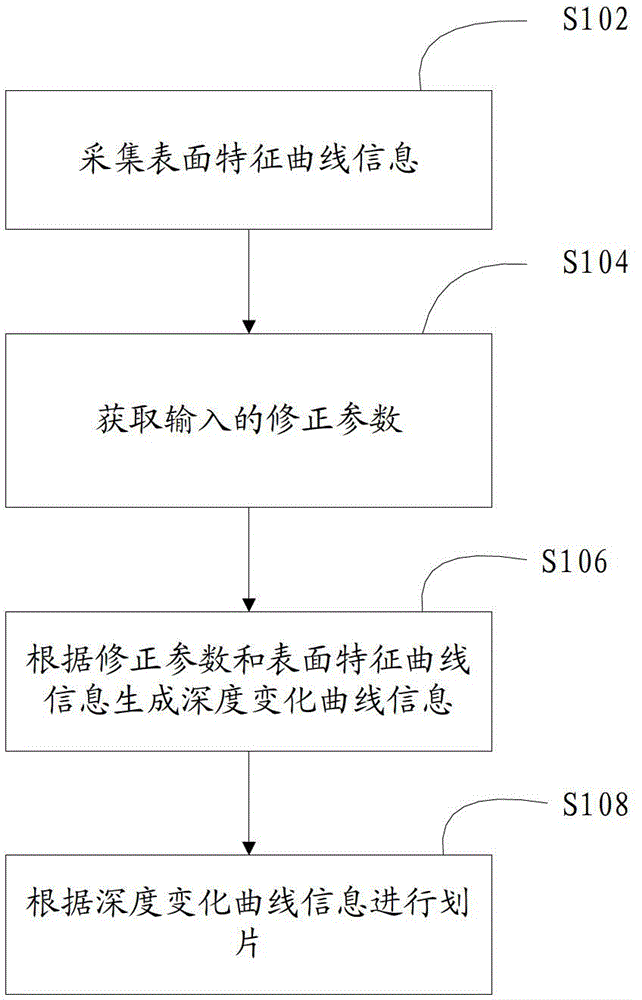

[0037] In one embodiment, such as figure 1 Shown, a kind of dicing method comprises the following steps:

[0038] Step S102, collecting surface characteristic curve information.

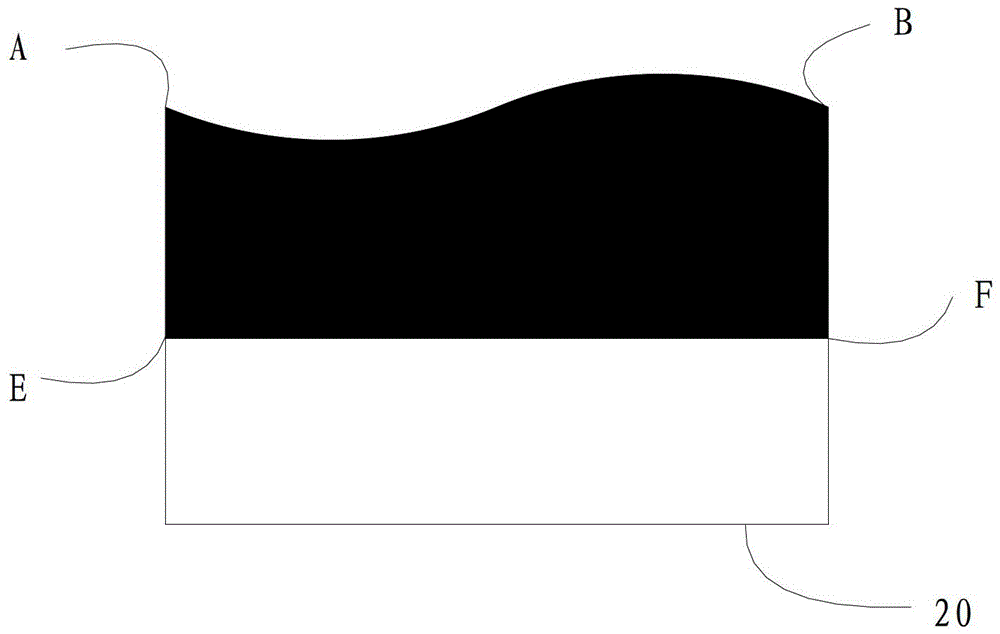

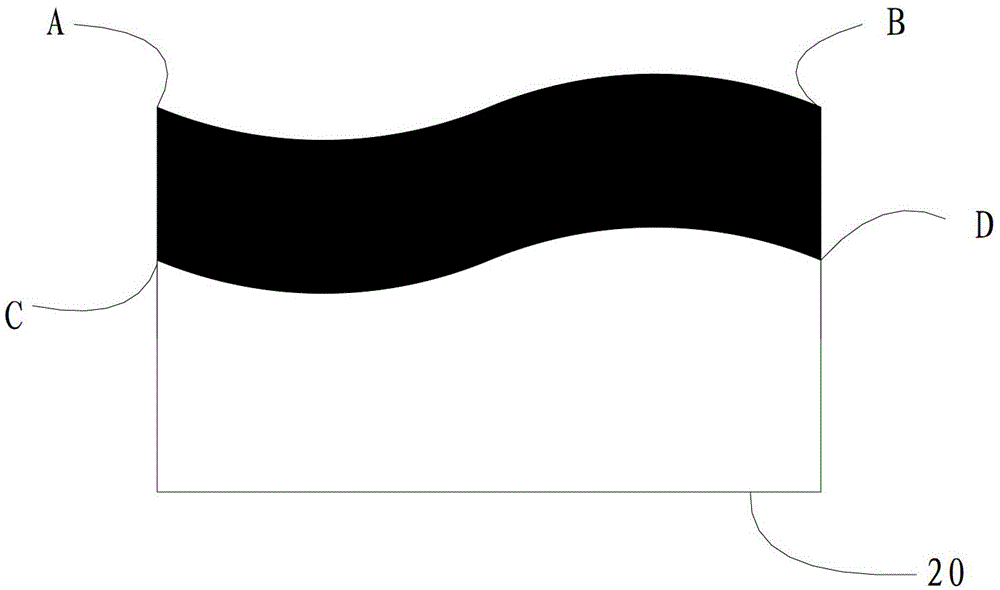

[0039] The surface characteristic curve information is the curve with undulations caused by the different thickness of the surface of the cutting object. For example, if figure 2 As shown, 20 is the wafer as the object to be cut, and curves A to B are the thickness change information of the upper surface at the cross section of the wafer. In this embodiment, the characteristic data of the surface of the cutting object can be collected by a displacement sensor, a scanner or a photoelectric conversion device, and then the surface characteristic curve information can be obtained through signal processing methods such as smoothing and filtering.

[0040] Step S104, acquiring the input correction parameters.

[0041] The correction parameter is the input parameter information. The correction paramet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com