Inner electrode silver paste for inductor and preparation method

An internal electrode and inductance technology, applied in cable/conductor manufacturing, transformer/inductor coil/winding/connection, conductive materials dispersed in non-conductive inorganic materials, etc. High RDC problems, to achieve the effect of complete printed electrodes, improved sintering compactness, and improved shrinkage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The main purpose of the present invention is to obtain a silver paste for internal electrodes with superior performance and low resistance by adjusting the reasonable ratio of crystalline silver powder, silver micropowder, silver oxide powder and organic carrier, and selecting a suitable particle size. The laminated silver paste and the porcelain body are compacted after debinding and firing, and there is no problem of porcelain external cracking and electrode internal cracking. At the same time, it reduces the resistivity of silver paste and the DC resistance of inductor products. The content of the ratio mentioned in the examples is not a limitation of the present invention, and other silver paste formula selections made under the concept of the present invention can be adapted to local conditions without substantial impact on the results.

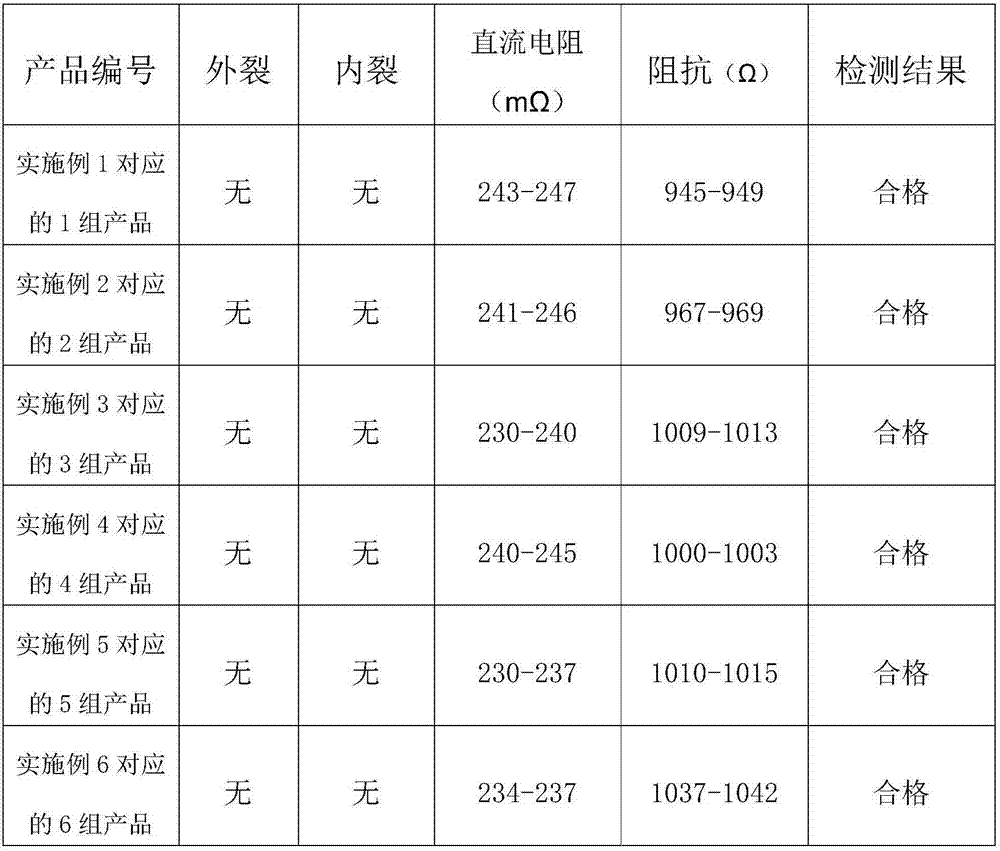

[0009] The formula design of the best embodiment of the present invention is shown in Table 1:

[0010] Table 1:

[0011]

[0012] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com