Sandwich glass hot-pressing method and device

A technology of laminated glass and hot pressing method, applied in the directions of lamination devices, lamination, chemical instruments and methods, etc., can solve problems such as glass failure, and achieve the purpose of prolonging service life, reducing energy consumption, reducing bubbles and delamination. effect of chance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The terms "first", "second", etc. used herein do not specifically refer to a sequence or order, nor are they used to limit the present application, but are only used to distinguish components or operations described with the same technical terms. .

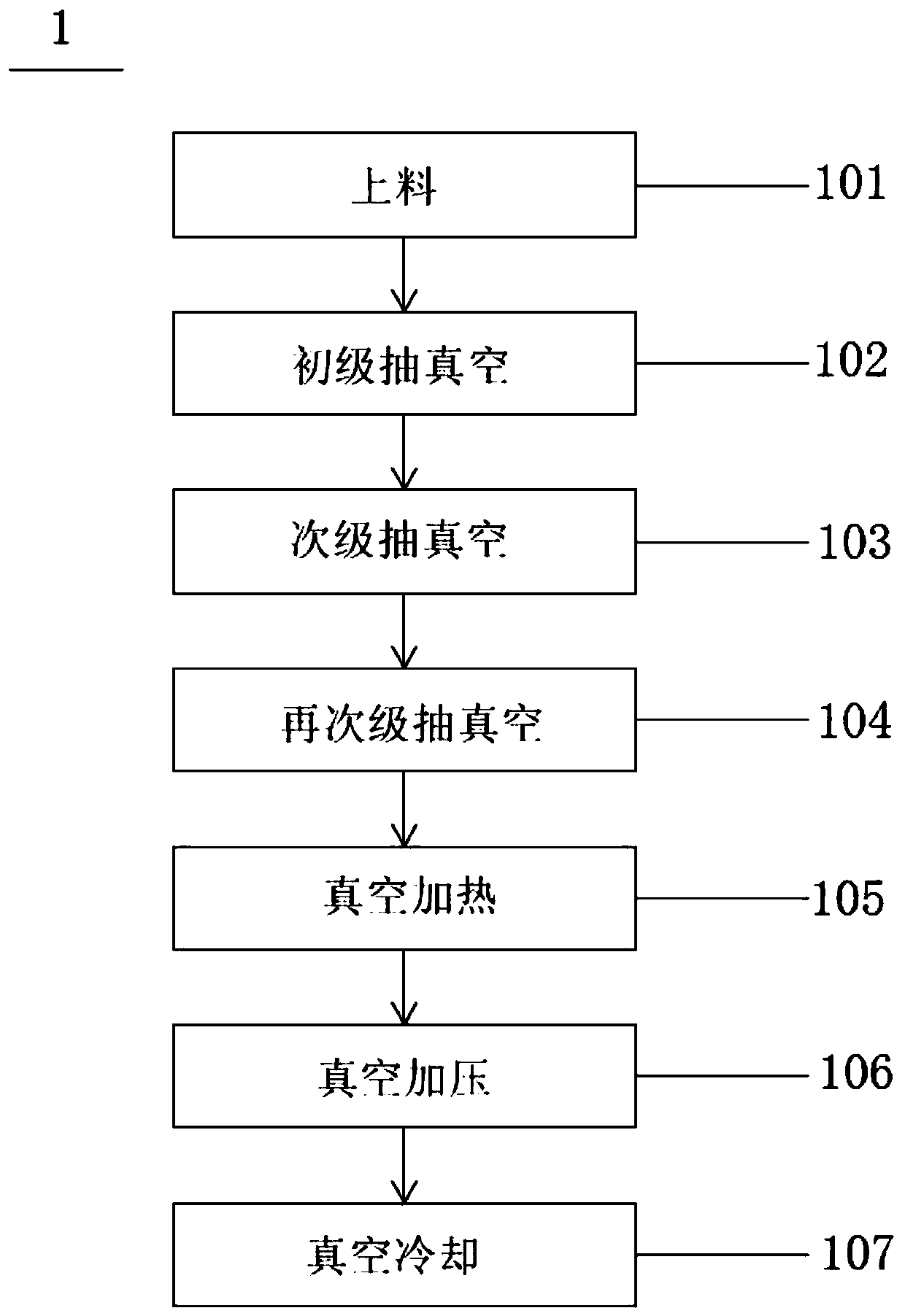

[0027] In one embodiment, the present invention discloses a laminated glass hot pressing method 1, please refer to figure 1 As shown, laminated glass hot pressing method 1 includes the following steps 101-107, wherein:

[0028] Step 101: loading materials. The laminated multilayer glass 3 is placed on the conveying device 4 .

[0029] In the present invention, there is no special requirement for the selection of the conveying device 4 , just refer to the conventional selection of those skilled in the art, for example, it may be a conveying roller or a conveying belt.

[0030] Specifically, the placement method of the multilayer glass 3 can be placed manually or by a mechanical arm, but it is not limited thereto, and thos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com