Bending-resisting plywood and manufacturing method thereof

A manufacturing method and technology for plywood, applied in the direction of manufacturing tools, chemical instruments and methods, wood layered products, etc., can solve the problems of plywood interlayer shedding, poor bending resistance of plywood, etc., to prevent delamination and improve integration. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

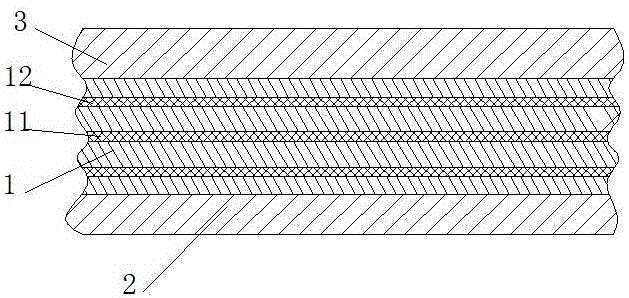

[0030] like figure 1 As shown, the present invention discloses a pressed wood chip layer and a first layer and a second layer glued on both sides of the wood chip layer; a metal mesh layer is embedded in the middle of the wood chip layer, and at least two braided mesh layers are symmetrically arranged on the metal mesh layer on both sides and embedded within the sawdust layer.

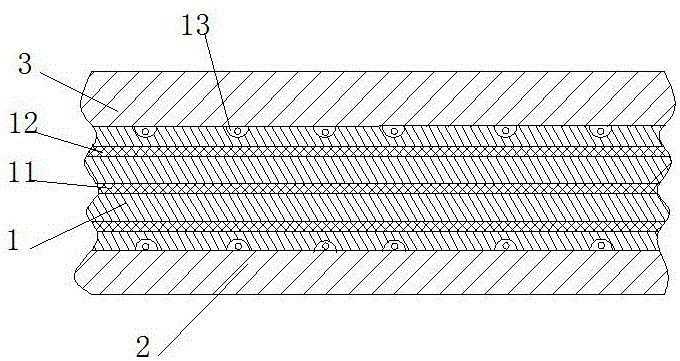

[0031] like figure 2 As shown, the surfaces on both sides of the wood chip layer are symmetrically provided with concave grooves for collecting residual glue during gluing, the concave grooves are arranged along the length direction of the wood chip layer, and polyolefin elastic fibers are arranged in the concave grooves.

[0032] The metal mesh layer adopts a mesh structure of 8-12 meshes woven by iron wires with a diameter of 0.8-1mm; the intersecting parts of the iron wires have interlocking grooves. The surface of the iron wire has non-slip concave-convex patterns.

[0033]The braided mesh laye...

Embodiment 2

[0036] In the plywood structure in embodiment 1, its sawdust layer 1 is made up of the material of following parts by weight: 30-40 parts of basswood particles with an average particle diameter of 1.5-4mm, 15-20 parts of basswood with an average particle diameter of 0.4-0.8mm Powder, 16-30 parts of rubber, and 5-8 parts of glue. When making the sawdust layer 1, generally adopt 32 parts of basswood particles, 20 parts of basswood powder, 20 parts of rubber, and 5 parts of glue; A non-quick-drying glue.

[0037] The sawdust layer 1 of this component can use basswood fibers to be scattered and distributed in the plywood, in addition, use basswood powder to fill the gaps in the sawdust layer 1, and use rubber and glue to further improve the compression resistance and bending resistance of the sawdust layer 1 , the thickness of the sawdust layer 1 can be arbitrarily designed, and it has integrity, so that the glued layer of the plywood avoids the position where the shear force is ...

Embodiment 3

[0039] The manufacturing method of this anti-bending plywood of embodiment 1, the steps are as follows:

[0040] Step 1: Select basswood particles and basswood powder and dry them so that the water content of both basswood particles and basswood powder is not higher than 4.5%; sterilize the basswood particles, basswood powder and rubber particles, and then put Basswood granules, rubber granules, glue and basswood powder are evenly mixed to form a mixture; the metal mesh layers are all placed in the pressing mold;

[0041] Step 2: evenly lay a 1.5-2mm thick mixture on the metal mesh layer; cover the mesh weaving mesh layer 12 woven from strands made of flax and nylon strands on the mixture; Cover 12 with 1-2mm mixed material; press the mixed material, metal mesh layer, and braided mesh layer 12 under a pressure of 5-8MPA and a temperature of 150-180°C for 3-5min;

[0042] Step 3: Turn over the front layer in the pressing mold, and repeat steps 2 and 3 to form a rough wood chip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com