Construction method and structure of antiskid surface of pavement

A road surface and surface layer technology, applied in the direction of roads, roads, pavement details, etc., can solve the problems of reduced roughness, reduced anti-skid performance, reduced friction between wheels and road surfaces, etc., to improve strength and stability, and reduce deformation. chance, the effect of improving the drainage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

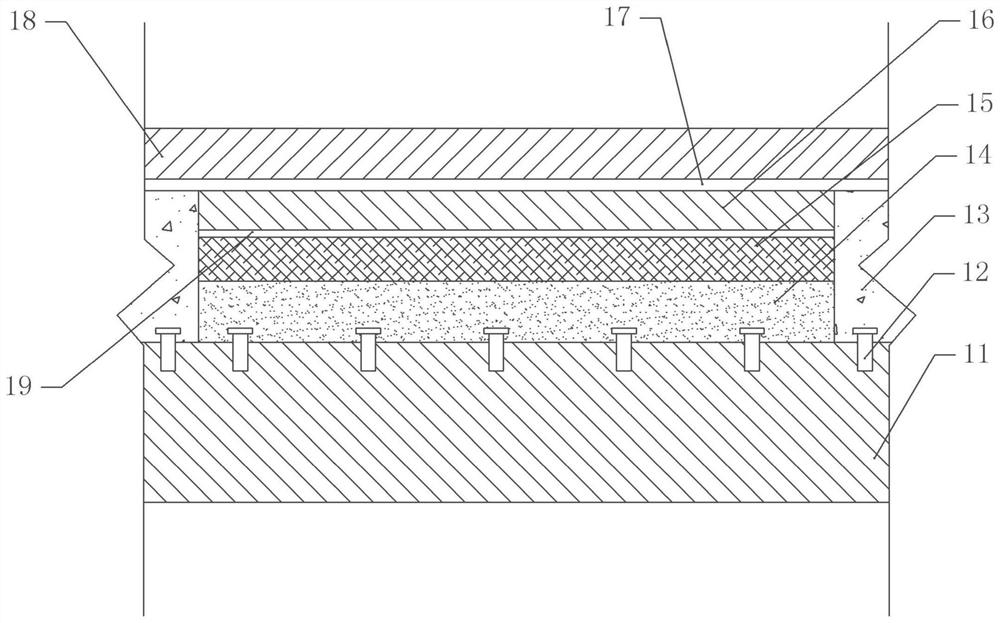

[0033] Basic attachment figure 1 As shown: a structure of a pavement anti-slide surface, including a drain layer 13 on both sides on the pavement 11, and a bonding layer 17 is sequentially laid from top to bottom between the drainage layers 13 on both sides. The surface layer 15 and the lower layer 14, and the bonding layer 17 is laid on the drainage surface layer 18 located above the drainage layer 13.

[0034] A construction method of the structure of a pavement 11 anti-slide surface, including the following steps:

[0035] Step 1: A number of pins 12 are laid in advance;

[0036] Step 2: The drainage layer 13 is laid on both sides of the road surface 11, and the specific drain layer 13 is prepared in: preparation 4 cm to 6 cm thick in the side of the pavement 11, the particle size of the crushed concrete is 5mm ~ 8mm, then The melted rubber is filled into the gap of the pulverized concrete, and the drainage layer 13 is constituted after the rubber is cooled, and the drainage la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com