A matrix type structure of a dustproof, waterproof and sound-transmitting film of a micro electro mechanical sensor

A micro-electromechanical sensor, dust-proof and waterproof technology, applied in the direction of electrostatic sensors, sensors, sensor types, etc., can solve the problems of high cost, slow efficiency, low efficiency, etc., to protect the dust-proof, waterproof and sound-permeable membrane, and reduce the probability of delamination Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

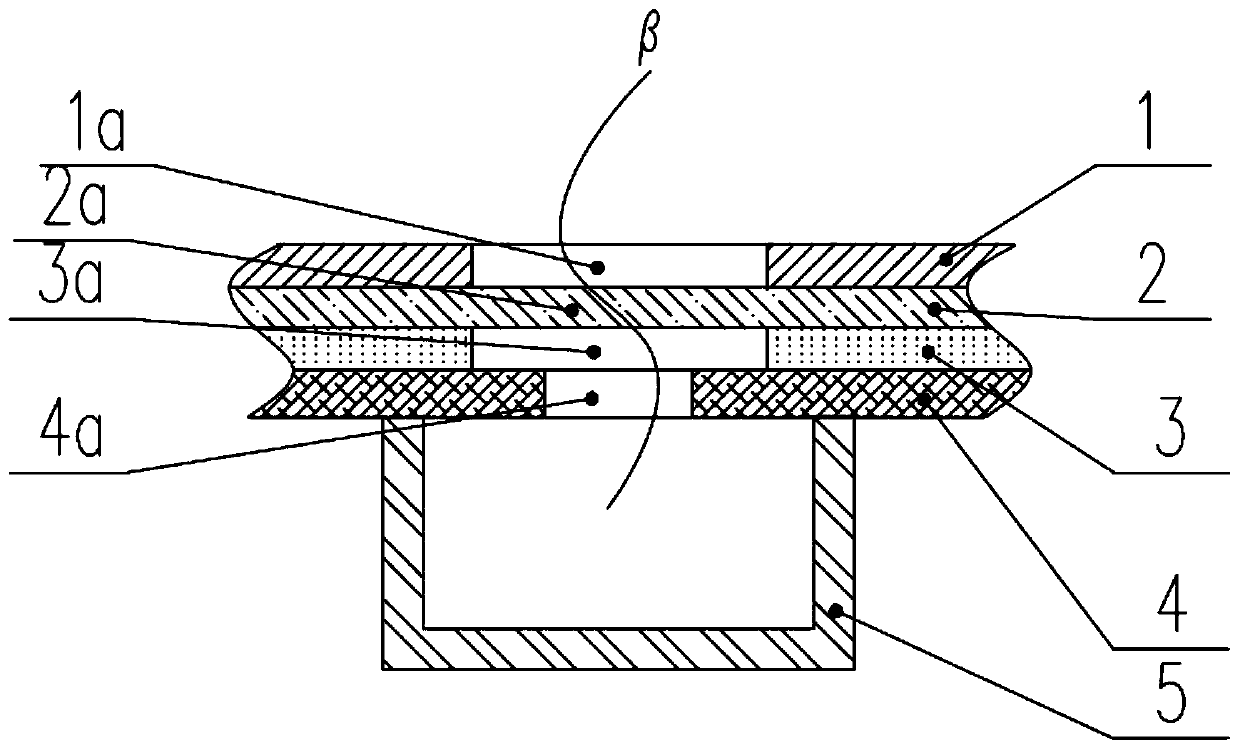

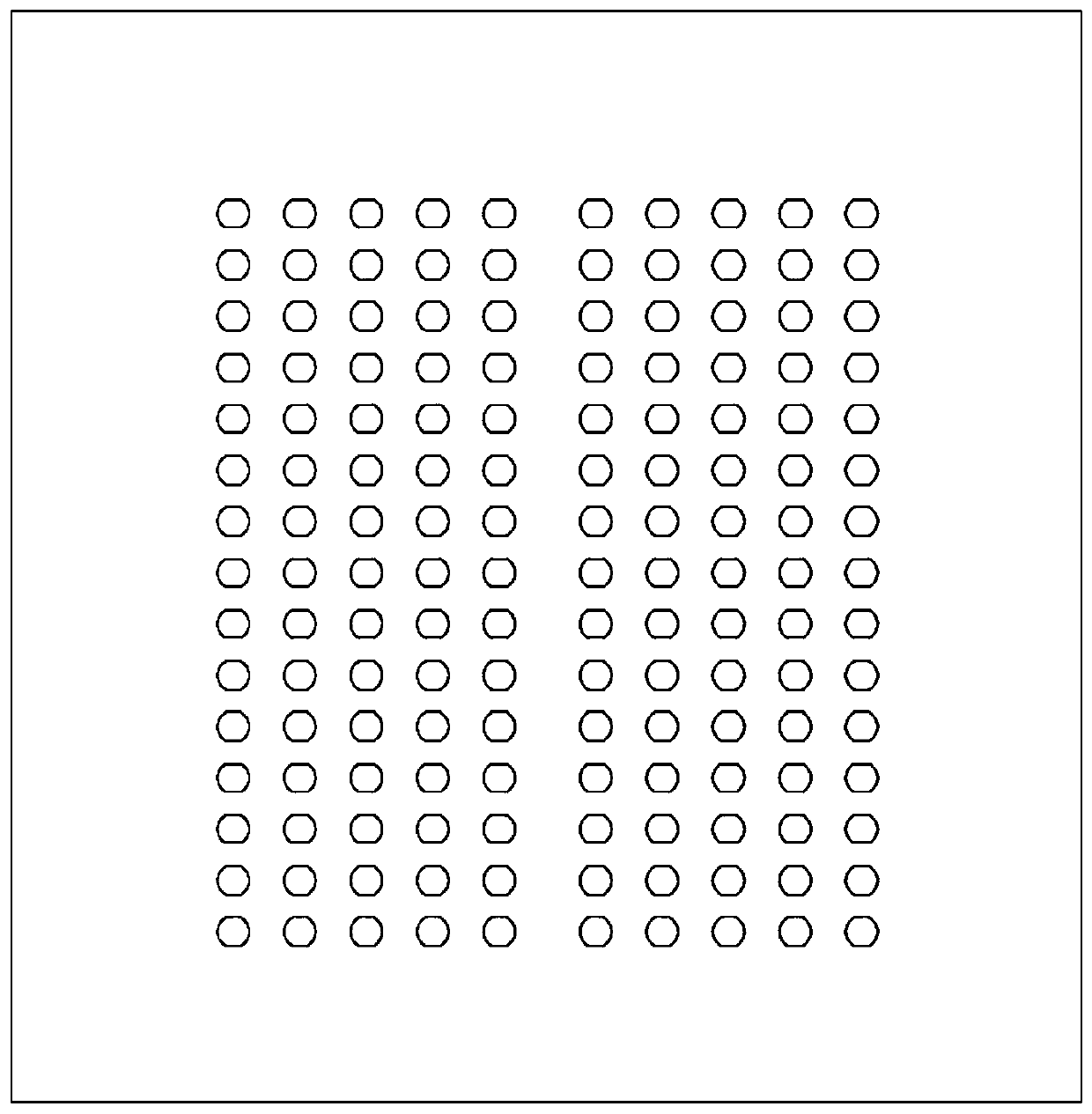

[0035] like figure 1 As shown, the structure of the dust-proof and waterproof sound-permeable membrane of the matrix micro-electromechanical sensor of the present embodiment includes a support layer 1, a dust-proof and waterproof sound-permeable membrane 2, an adhesive 3, a PCB board 4 and an acoustic sensor 5, and the support layer One side of 1 is sticky, sticking to one side of the dustproof and waterproof sound-permeable membrane 2, and the other side of the dustproof and waterproof sound-permeable membrane 2 is glued to the upper surface of the PCB 4 by the adhesive 3, and an acoustic sensor 5 is installed on the lower surface of the PCB 4; The support layer 1, the dustproof and waterproof sound-permeable membrane 2, the adhesive 3 and the PCB board 4 are respectively provided with the acoustic sensor 5 at the position corresponding to the support layer sound hole 1a, the dust-proof and waterproof sound-permeable membrane vibration area 2a, the adhesive sound hole 3a and t...

Embodiment 2

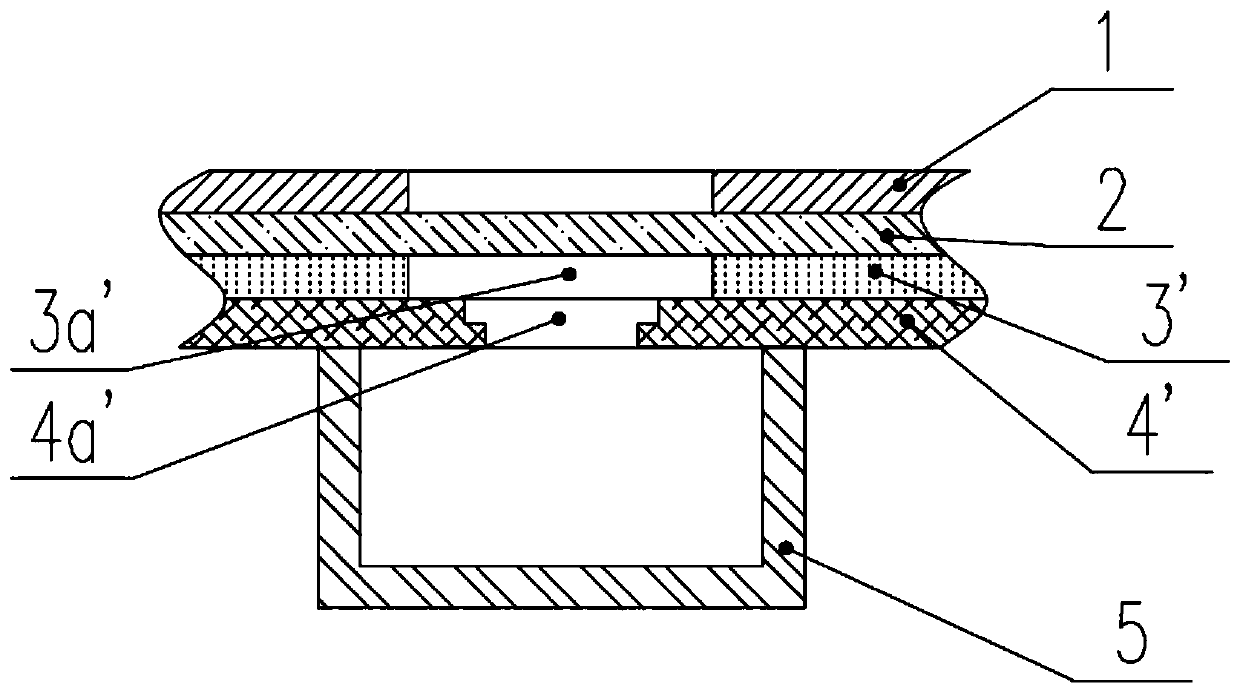

[0041] like image 3 As shown, the structure of the matrix microelectromechanical sensor dustproof and waterproof sound-permeable membrane of the present embodiment includes a support layer 1, a dustproof and waterproof sound-permeable membrane 2, an adhesive 3', a PCB board 4' and an acoustic sensor 5, and figure 1 and 2The scheme of embodiment 1 shown in is similar, the difference is that the PCB sound hole 4a' of the PCB board 4' is a stepped hole with a wide top and a narrow bottom. Described adhesive 3' adopts except that hot-melt adhesive, hot-press adhesive, double-sided adhesive etc. are able to bear the high temperature of 260 ℃ and invariant material, also can adopt glue. When the glue with almost no thickness is used for the adhesive 3', since the sound hole 4a' of the PCB board is a stepped hole, a certain height is provided to effectively prevent the dustproof and waterproof sound-permeable membrane 2 from touching the PCB board 4' during the process of vibration...

Embodiment 3

[0044] like Figure 4 Shown, the structure of the dust-proof and waterproof sound-permeable membrane of the matrix microelectromechanical sensor of the present embodiment, and figure 1 and 2 The embodiment 1 shown in the scheme is similar, the difference is that the support layer 1 is canceled, and only includes the dustproof and waterproof sound-permeable membrane 2, the adhesive 3, the PCB board 4 and the acoustic sensor 5, and the dustproof and waterproof sound-permeable membrane 2 is composed of The adhesive 3 is stuck on the upper surface of the PCB 4 , and the acoustic sensor 5 is installed on the lower surface of the PCB 4 . The acoustic sensor 5, the vibration area 2a of the dustproof and waterproof sound-permeable membrane, the adhesive sound hole 3a, and the PCB sound hole 4a form an acoustic channel β.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com