Lead frame suitable for coplanar plastic package optocoupler packaging

A technology of lead frame and optocoupler, which is applied in the direction of semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve the problems of reliability impact, low curvature of photoconductive adhesive, and increase the types of raw materials in the plastic package of optocoupler, etc., to achieve The effect of reducing the probability of delamination, reducing the types of materials, and improving the connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

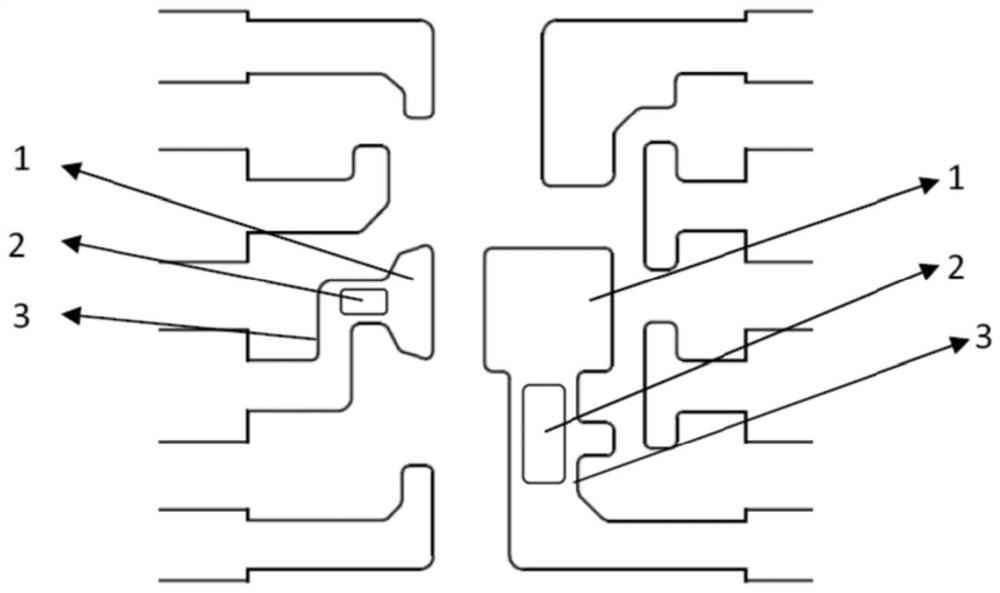

[0023] A lead frame suitable for coplanar plastic encapsulated optocoupler packages, such as figure 1 As shown in the figure, the lead frame substrate consists of two substrates 1, each part of the substrate 1 has the same function, both of which are used to carry the light-emitting chip or the light-receiving chip, the shape is approximately rectangular, and the area is different; one end of the substrate 1 passes through the lining The bottom epitaxial region 3 is connected with the inner pins, the flow suppression holes 2 are distributed on the substrate epitaxial region 3, and the flow suppression holes 2 are rounded rectangular flow suppression holes, which appear in the form of single holes. The length of the long side of the rounded rectangular flow suppression hole is 0.7 mm to 1.4 mm, and the distance from the edge of the flow suppression hole 2 to the edge of the substrate epitaxial region 3 is 0.2 mm to 0.5 mm. The single-rounded rectangular choke hole is suitable f...

Embodiment 2

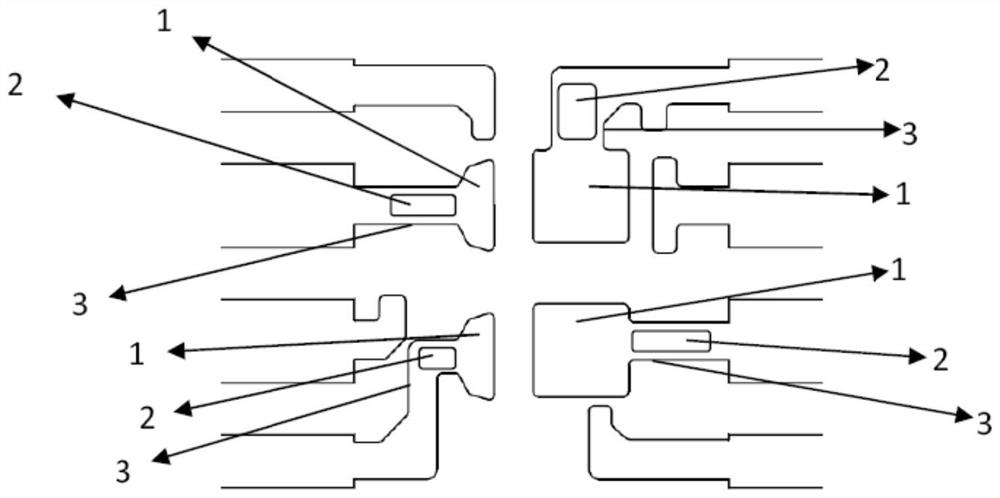

[0025] A lead frame suitable for coplanar plastic encapsulated optocoupler packages, such as figure 2 As shown, the lead frame substrate is composed of 4 substrates 1, the shape is approximately rectangular, the area is unequal, one end edge of each substrate 1 is connected to the inner pin, and the flow suppression holes 2 are distributed on the substrate epitaxy area 3, The flow suppression hole 2 is a rounded rectangular flow suppression hole in the form of a single hole. The size of the rounded rectangular flow suppression hole and the position on the epitaxial region 3 of the substrate are the same as those of the first embodiment.

Embodiment 3

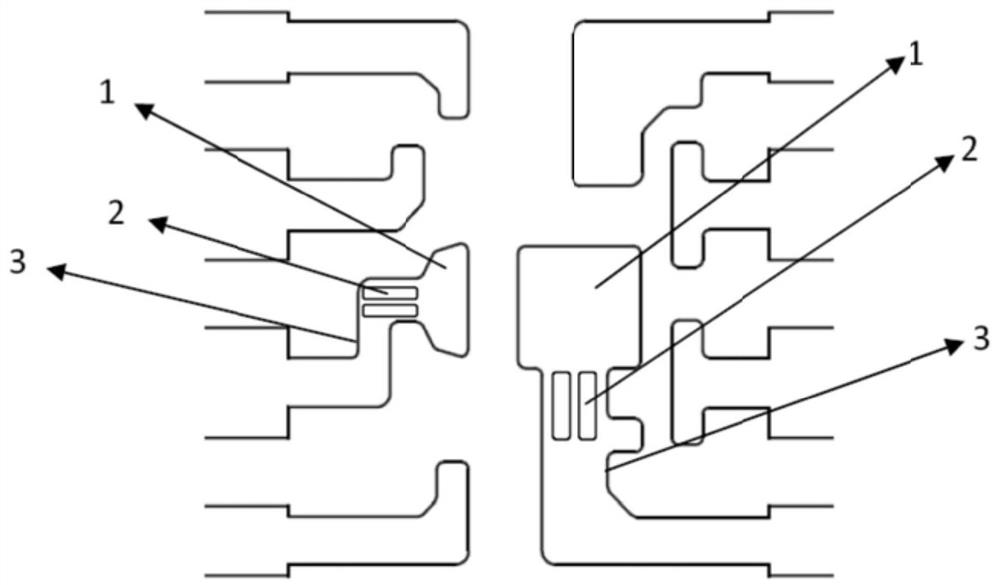

[0027] A lead frame suitable for coplanar plastic encapsulated optocoupler packages, such as image 3 As shown in the figure, the lead frame substrate is composed of two substrates 1, which are approximately rectangular in shape and different in area. The flow suppression hole 2 is a rounded rectangular flow suppression hole, which appears in the form of two rows and one column or one row and two columns.

[0028] The length of the long side of the rounded rectangular flow suppression holes arranged in two rows and a single row is 0.7 mm to 1.4 mm, and the distance from the outermost edge of the flow suppression hole 2 to the edge of the substrate epitaxial region 3 is 0.2 mm to 0.5 mm.

[0029] The length of the long side of the rounded rectangular flow suppression holes arranged in a single row and two columns is 0.3mm-0.7mm, and the distance from the outermost edge of the flow suppression hole 2 to the edge of the substrate epitaxial region 3 is 0.2mm-0.5mm. The multi-roun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com