Polycrystalline cubic boron nitride composite sheet and preparation method thereof

A technology of cubic boron nitride and polycrystalline cubic, which is applied in other manufacturing equipment/tools, turbines, engine components, etc., can solve the problem of large difference in thermal expansion coefficient between the substrate and the CBN layer, poor crack resistance and collapse resistance of the product, and reduced Composite sheet thermal stability and other issues, to achieve the effect of reducing metal content, improving product crack resistance, and improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

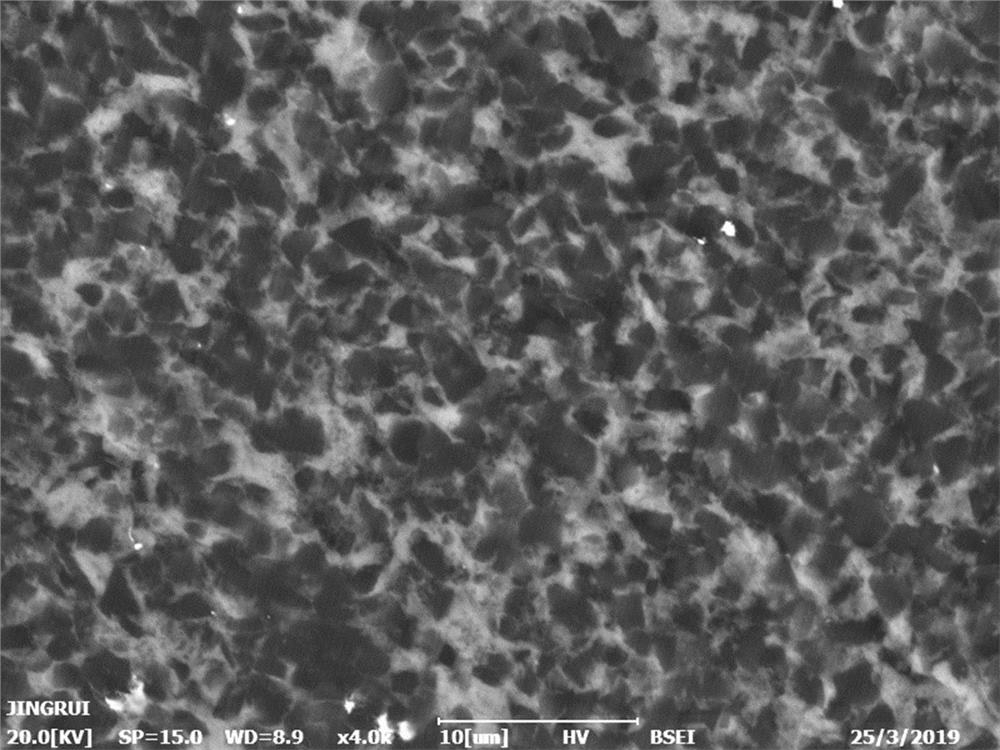

[0046] This embodiment provides a method for preparing a titanium-transition metal solid-solution boride ceramic matrix polycrystalline cubic boron nitride composite sheet, which uses a titanium-tungsten boride ceramic sheet as a matrix, a ceramic binder and a cubic boron nitride mixed blank bulk as a cubic boron nitride layer.

[0047] Titanium tungsten boride (Ti 0.5 W 0.5 B 2 ) The ceramic sheet is produced by Suqian Dete Materials Co., Ltd., with a thickness of 4 mm and a diameter of 58 mm.

[0048] The cubic boron nitride layer in this embodiment is composed of the following components by mass: 50 parts of cubic boron nitride with an average particle size of 2 microns and 50 parts of titanium carbide with an average particle size of 2 microns.

[0049] This embodiment provides a method for preparing a titanium-tungsten-boride ceramic matrix polycrystalline cubic boron nitride composite sheet, which includes the following steps:

[0050] Step 1: Mix cubic boron nitride...

Embodiment 2

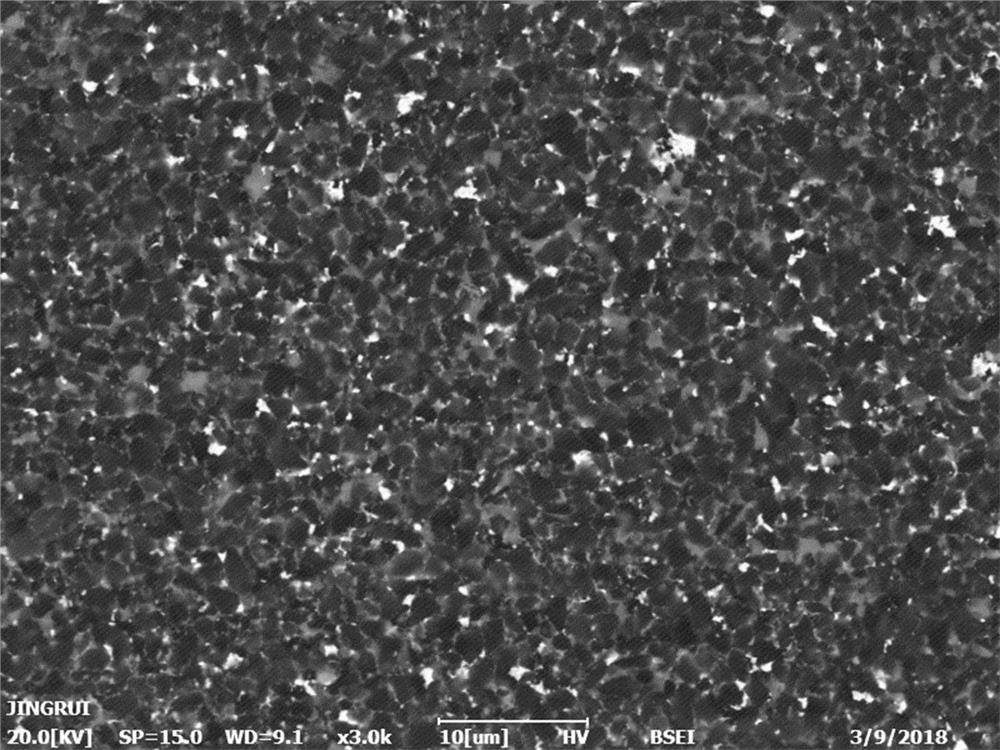

[0062] This embodiment provides a method for preparing a titanium-transition metal solid-solution boride ceramic sheet matrix polycrystalline cubic boron nitride composite sheet, which is made of a titanium diboride ceramic sheet as a matrix, and a metal binder is mixed with cubic boron nitride The green body acts as a layer of cubic boron nitride.

[0063] Titanium diboride (TiB) used in this example 2 ) The ceramic sheet is produced by Suqian Dete Materials Co., Ltd., with a thickness of 4 mm and a diameter of 58 mm.

[0064] The cubic boron nitride layer in this embodiment is composed of the following components by mass: 90 parts of cubic boron nitride with an average particle size of 0.1 micron and 10 parts of metallic aluminum powder with an average particle size of 1 micron.

[0065] This embodiment provides a method for preparing a titanium diboride ceramic matrix polycrystalline cubic boron nitride composite sheet, which includes the following steps:

[0066] Step 1:...

Embodiment 3

[0070] This embodiment provides a method for preparing a titanium-transition metal solid-solution boride ceramic sheet substrate polycrystalline cubic boron nitride composite sheet, which is made of a titanium vanadium boride ceramic sheet as a matrix, and a ceramic binder and cubic boron nitride are mixed The green body acts as a layer of cubic boron nitride.

[0071] Titanium vanadium boride (Ti 0.5 V 0.5 B 2 ) The ceramic sheet is produced by Suqian Dete Materials Co., Ltd., with a thickness of 4 mm and a diameter of 58 mm.

[0072] The cubic boron nitride layer in this embodiment is composed of the following components by mass: 10 parts of cubic boron nitride with an average particle size of 30 microns and 90 parts of titanium carbide with an average particle size of 30 microns.

[0073] This embodiment provides a method for preparing a titanium vanadium boride ceramic matrix polycrystalline cubic boron nitride composite sheet, which includes the following steps:

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com