Automatic control rubber mixing extruding device and control method

An automatic control and rubber mixing technology, applied in the direction of manufacturing tools, material molding presses, presses, etc., can solve the problems of low automation, low processing quality, and low production efficiency, and achieve high automation and high processing quality. High, high production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to facilitate the understanding of the present invention, further explanations will be given below in conjunction with specific examples, which do not constitute limitations on the examples of the present invention.

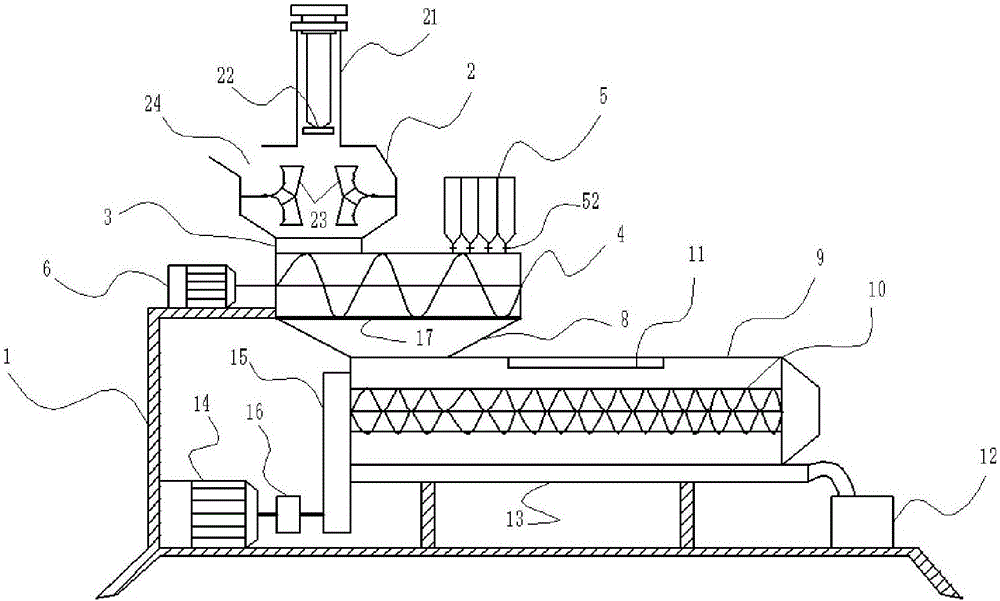

[0022]An automatic control rubber mixing and extruding device, mainly divided into a pre-mixing module and a second-stage mixing and extruding module, the first-stage pre-mixing module and the second-stage mixing and extruding module are fixed by a bracket 1 to form an upper and lower structure, The first section of the pre-mixing module includes a mechanical plasticating room 2, wherein a cylinder 21 is arranged above the mechanical plasticating room 2, and the cylinder 21 is connected with the mechanical plasticating room 2 through a weight 22, and a shearer is arranged inside the mechanical plasticating room 2 23. There is a material inlet 24 on the side. The mechanical plasticating chamber is the first step in rubber premixing, which can achiev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com