Fuel injection device

A fuel injection device and fuel injection technology, which are applied in the directions of fuel injection control, combustion engine, internal combustion piston engine, etc., can solve the problems of difficulty in fully reducing soot, and inability to ensure the time for sufficient fuel mixing, and achieve the effect of reducing combustion noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings.

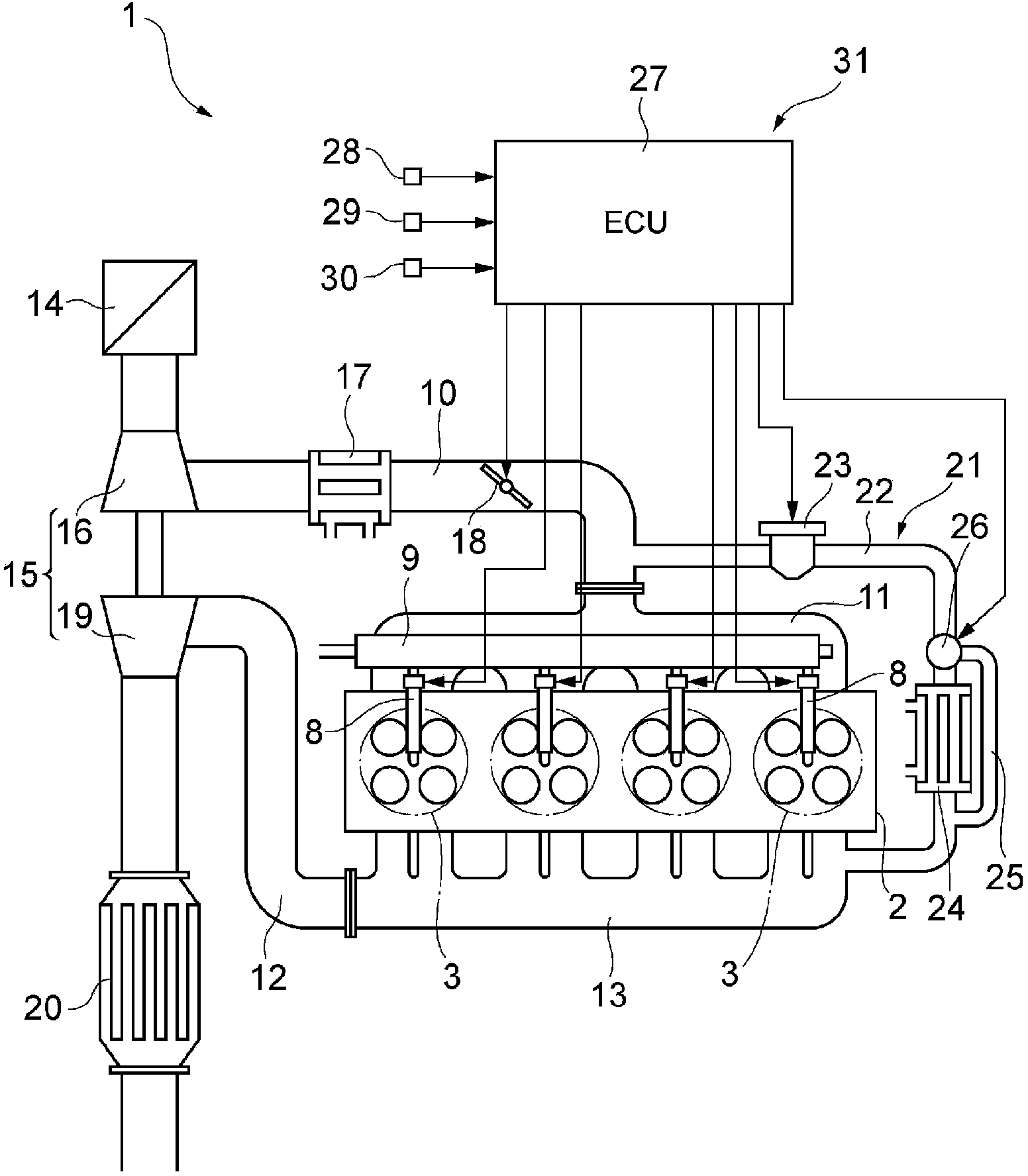

[0030] figure 1 It is a schematic configuration diagram showing a diesel engine including the fuel injection device according to the present embodiment. The diesel engine 1 according to the present embodiment is an inline four-cylinder diesel engine. The diesel engine 1 includes an engine body 2 in which four cylinders 3 are provided.

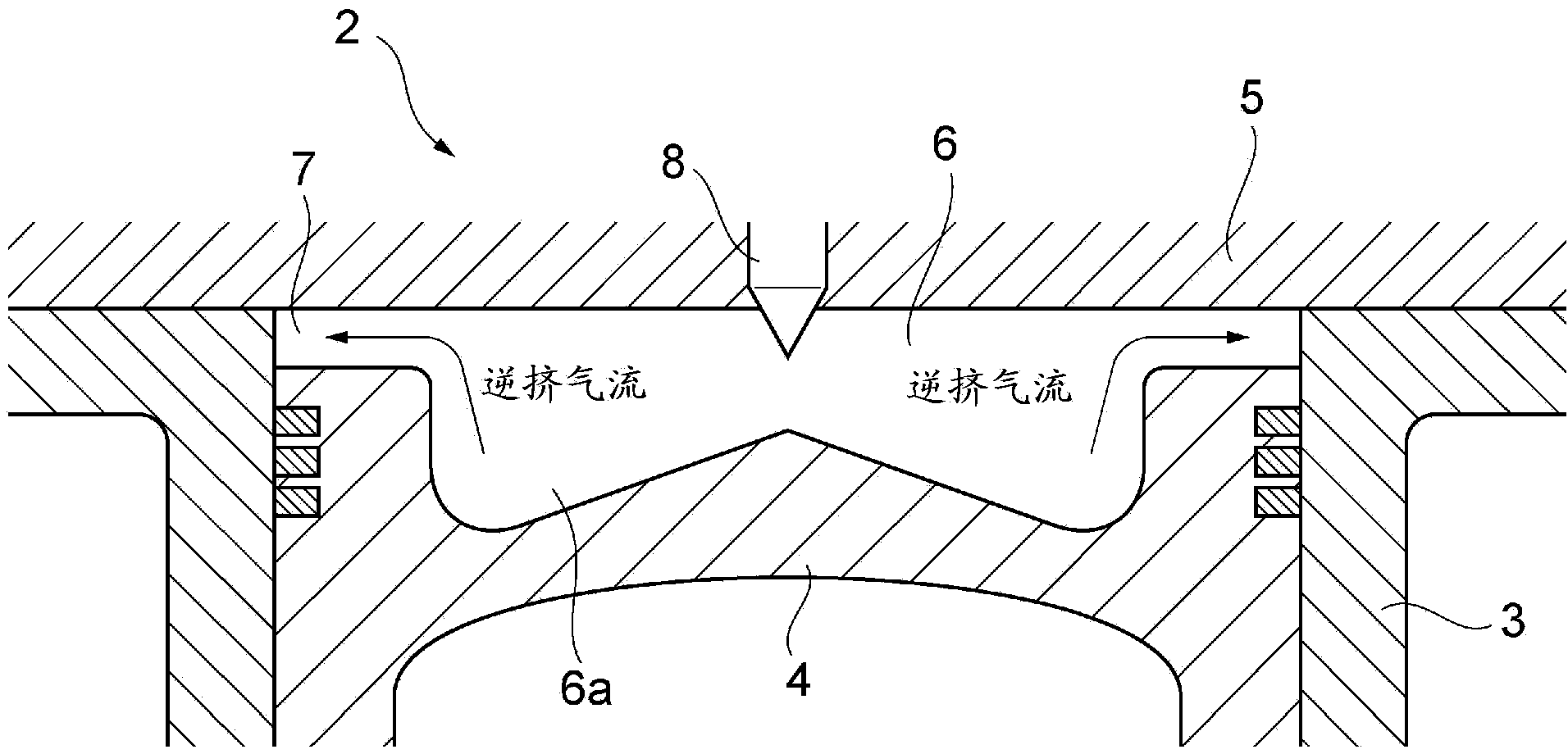

[0031] Such as figure 2 As shown, a piston 4 is accommodated in the cylinder 3 . A cylinder head 5 is disposed above the cylinder 3 . The space surrounded by the cylinder 3 , the piston 4 and the cylinder head 5 constitutes a combustion chamber 6 . A chamber 6 a constituting a part of the combustion chamber 6 is formed at the top of the piston 4 . A region between a portion of the piston 4 on the outer peripheral side of the chamber 6 a and the cylinder head 5 constitutes a squish region 7 .

[0032] Injectors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com