Fine powder mixing device as well as concrete mixing equipment and concrete mixing process using fine powder mixing device

A mixing device and concrete technology, which is applied in the field of concrete, can solve the problems of high installed power of the mixer, and achieve the effects of short mixing time, selection of rotation speed, and fewer moving parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the drawings and embodiments.

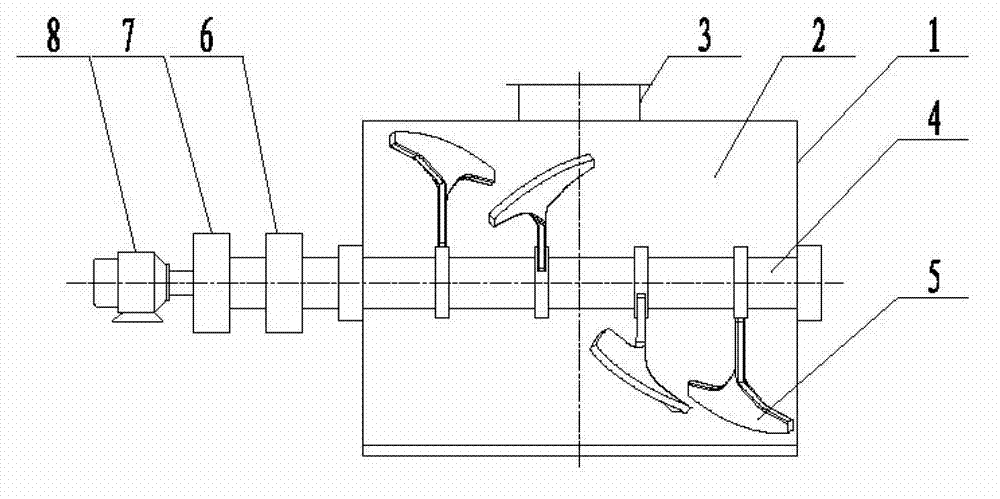

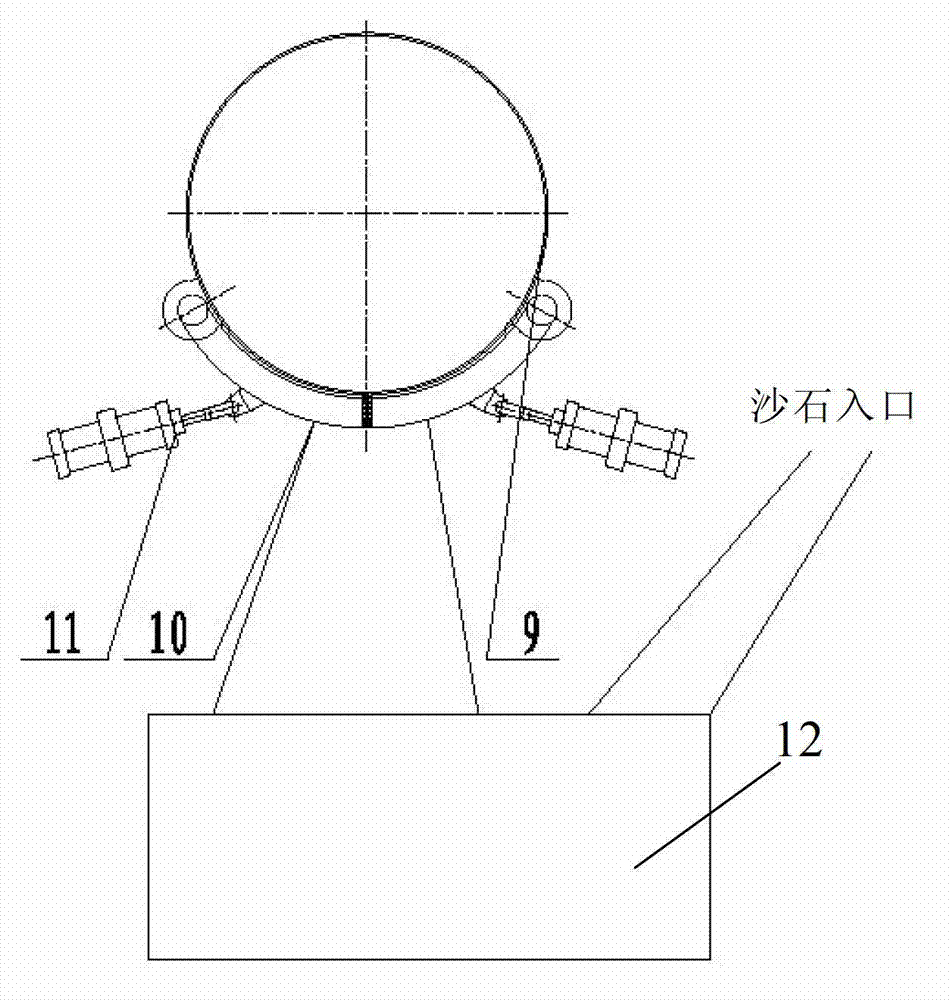

[0016] Such as figure 1 As shown, the fine powder mixing device of the present invention includes a casing main body 1, the casing main body 1 is a horizontal cylindrical body, and the inside of the barrel is the mixing chamber 2. The inner wall of the casing body 1 is provided with a wear-resistant layer 9. There is a horizontal main shaft 4 in the main body 1 of the casing. On the main shaft 4, there are a plurality of mixing blades 5 with different warping directions, that is, the types and directions of the mixing blades 5 are different. The main shaft 4 is connected to the motor 8 through the speed reducer 6 and the transmission 7 outside the casing body 1. The speed of the spindle 4 is constant, or continuously adjustable, or divided into multiple speeds. The feed inlet 3 of the device is a vertical inlet, located in the upper part of the main body 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com