Electrode slurry mixing process

A technology for electrode slurry and negative electrode slurry, which is applied in mixers, mixers with rotating containers, chemical instruments and methods, etc., can solve the problems of long mixing time and sufficient mixing of electrode slurries, so as to improve the high current Discharge performance, improve labor efficiency, overcome the effect of high current performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This example is used to illustrate the electrode slurry mixing method provided by the present invention.

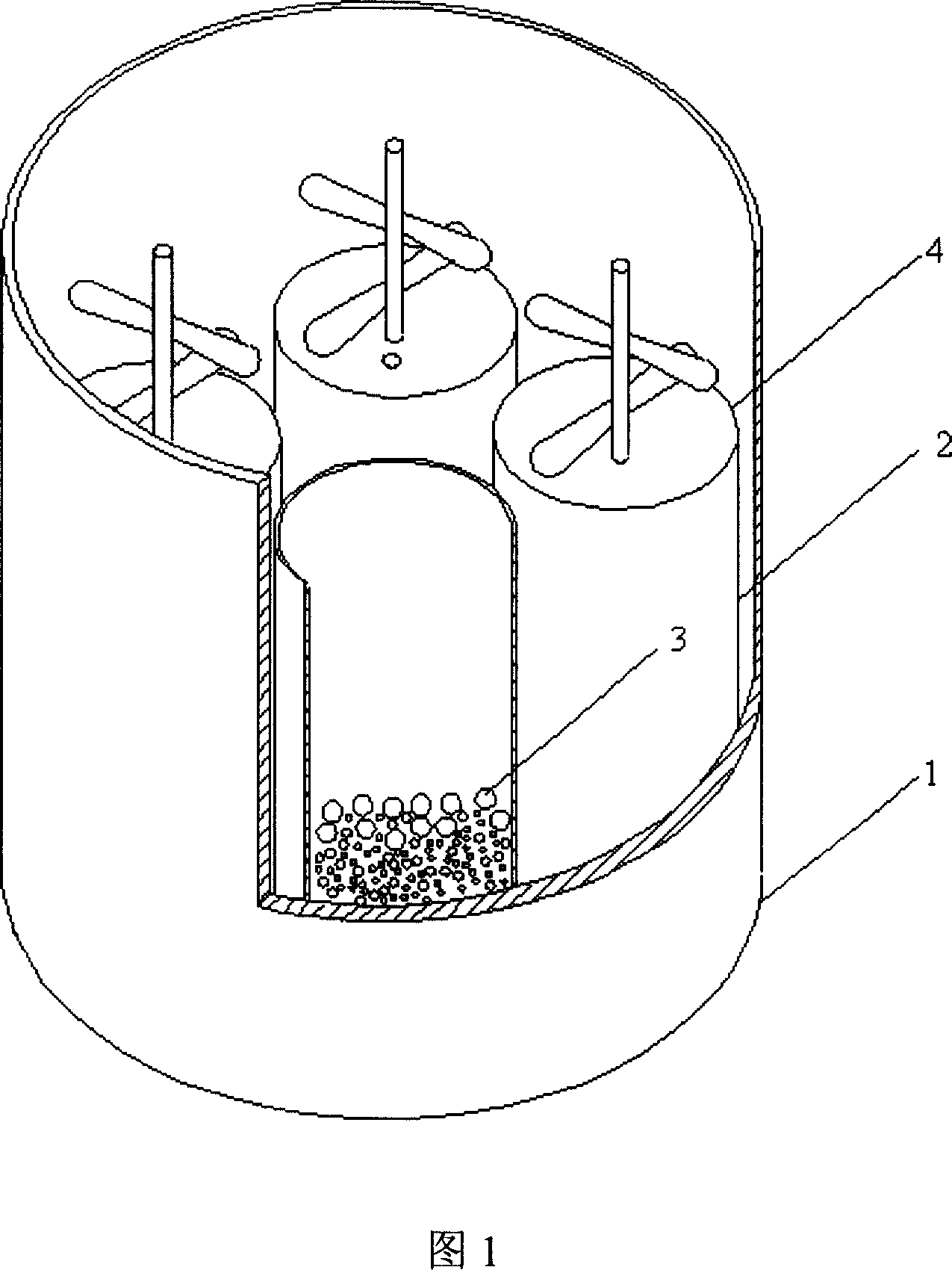

[0025] Put 10 kilograms of lithium cobalt oxide powder into four ball milling tanks of the planetary ball mill shown in Figure 1, each tank contains 2.5 kilograms, and 12 diameters of 20 mm and 200 diameters of 10 mm, 1800 agate balls with a diameter of 6 mm were ground for 60 minutes at a rotation speed of 250 rpm and a revolution speed of 350 rpm to obtain a refined and homogenized lithium cobalt oxide powder.

[0026] Then the resulting refined and homogenized lithium cobalt oxide powder and 0.5 kg of acetylene black, 4.0 kg of N-methylpyrrolidone (NMP), and 0.5 kg of polytetrafluoroethylene (PVDF) are equally divided into four parts and put into four ball mills mixing in a tank, and then continue grinding for 120 minutes at an autorotation speed of 280 rpm and a revolution speed of 360 rpm to obtain the electrode slurry S1.

Embodiment 2

[0028] This example is used to illustrate the electrode slurry mixing method provided by the present invention.

[0029] 8.5 kilograms of spherical nickel hydroxide powder are evenly packed into four ball milling tanks of the planetary ball mill shown in Figure 1, and each ball milling tank is put into 10 ball mills with a diameter of 20 mm and 150 ball mills with a diameter of 10 mm. 1200 agate balls with a diameter of 6 mm were ground for 70 minutes at a rotation speed of 250 rpm and a revolution speed of 350 rpm to obtain refined and homogenized spherical nickel hydroxide powder.

[0030] Then the spherical nickel hydroxide powder of gained refinement and homogenization is mixed with 75 grams of titanium dioxide, 200 grams of carbon black, 100 grams of polytetrafluoroethylene, 5 grams of hydroxypropyl methylcellulose and 1 kilogram of deionized water respectively in Mix in a ball mill jar, and then continue to grind for 140 minutes at an autorotation speed of 280 rpm and a ...

Embodiment 3

[0032] This example is used to illustrate the electrode slurry mixing method provided by the present invention.

[0033] 0.6 kilograms of hydroxymethyl cellulose, 1.5 kilograms of styrene-butadiene rubber (SBR) latex, 2.8 kilograms of graphite and 3.8 kilograms of water are all loaded into two relative ball milling tanks of the planetary ball mill shown in Figure 1, and 430 grams of oxidized Zinc, 1.5 kilograms of titanium dioxide, 3.5 kilograms of carbon black, 2.0 kilograms of polytetrafluoroethylene, 100 grams of hydroxypropyl methylcellulose and 2 kilograms of deionized water are loaded into the other two ball milling jars of the ball mill, and each ball milling jar Put 30 agate balls with a diameter of 20 mm, 300 agate balls with a diameter of 10 mm, and 2800 agate balls with a diameter of 6 mm. After covering the cover of the ball mill jar, the rotation speed at 150 rpm and the revolution at 200 rpm Speed milling for 0.5 hours to obtain fine and homogenized negative el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com