Diesel oil engine

A diesel engine and pre-injection technology, which is applied in the direction of engine control, combustion engine, machine/engine, etc., can solve the problems such as the inability to form pre-mixed gas, and achieve the effect of simplifying fuel injection control and preventing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

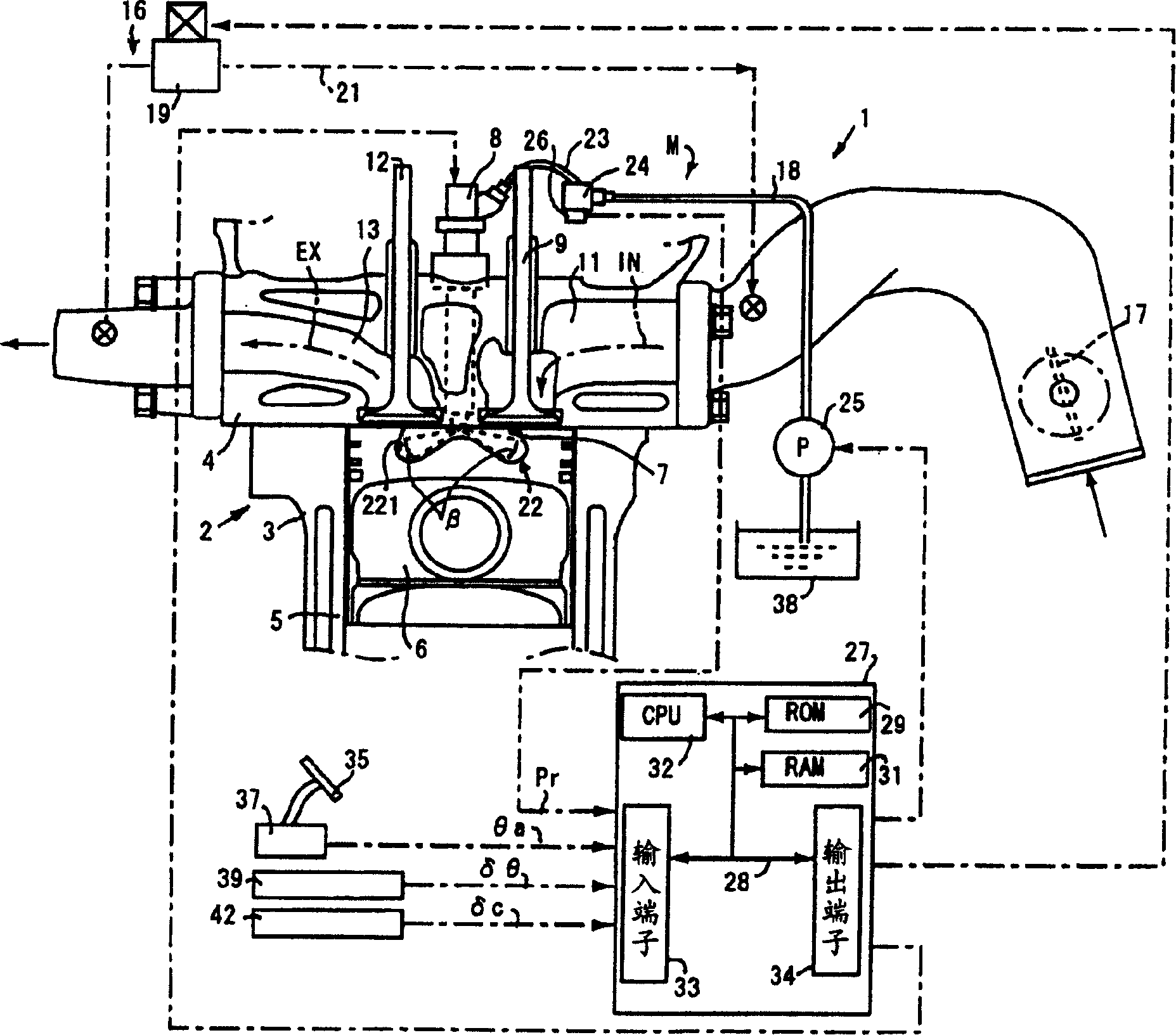

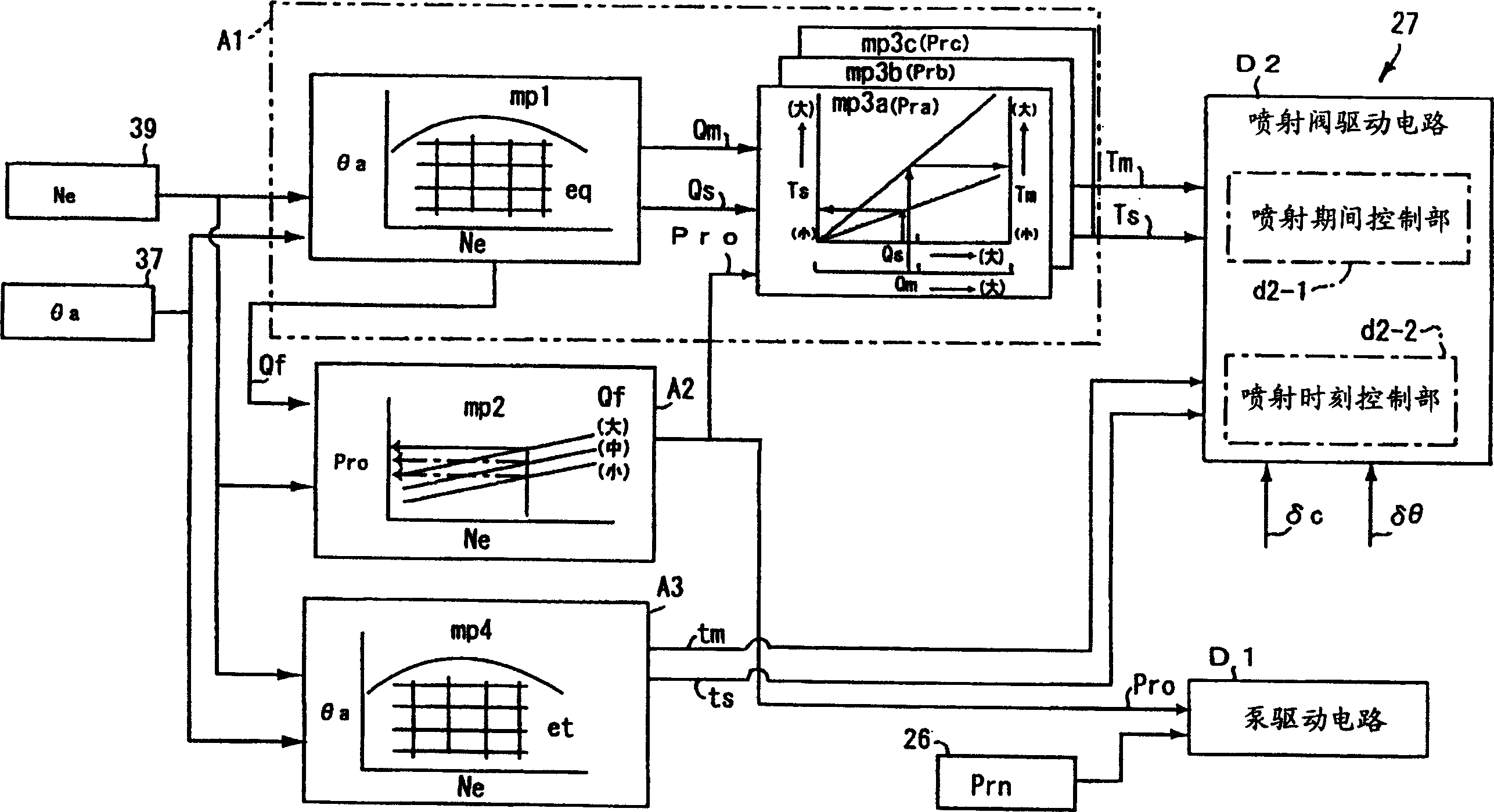

[0038] figure 1 Shown is an overall structure of a diesel engine 1 according to an embodiment of the present invention and a fuel injection device M mounted on a main body 2 of the diesel engine (hereinafter referred to as the engine) 1 .

[0039] The main body 2 of the engine 1 includes: a cylinder block 3 , a cylinder head 4 combined thereon, a cylinder head cover not shown in the figure, an oil pan and the like. The engine 1 is a multi-cylinder engine having a plurality of cylinders of the same structure. However, here, in order to avoid redundant description, one cylinder will be mainly described. Here, in the cylinder block 3 , the internal cylinder 5 is equipped with a piston 6 that can slide up and down, and a combustion chamber 7 with variable volume is formed in the lower space of the cylinder 5 , piston 6 , and cylinder head 4 .

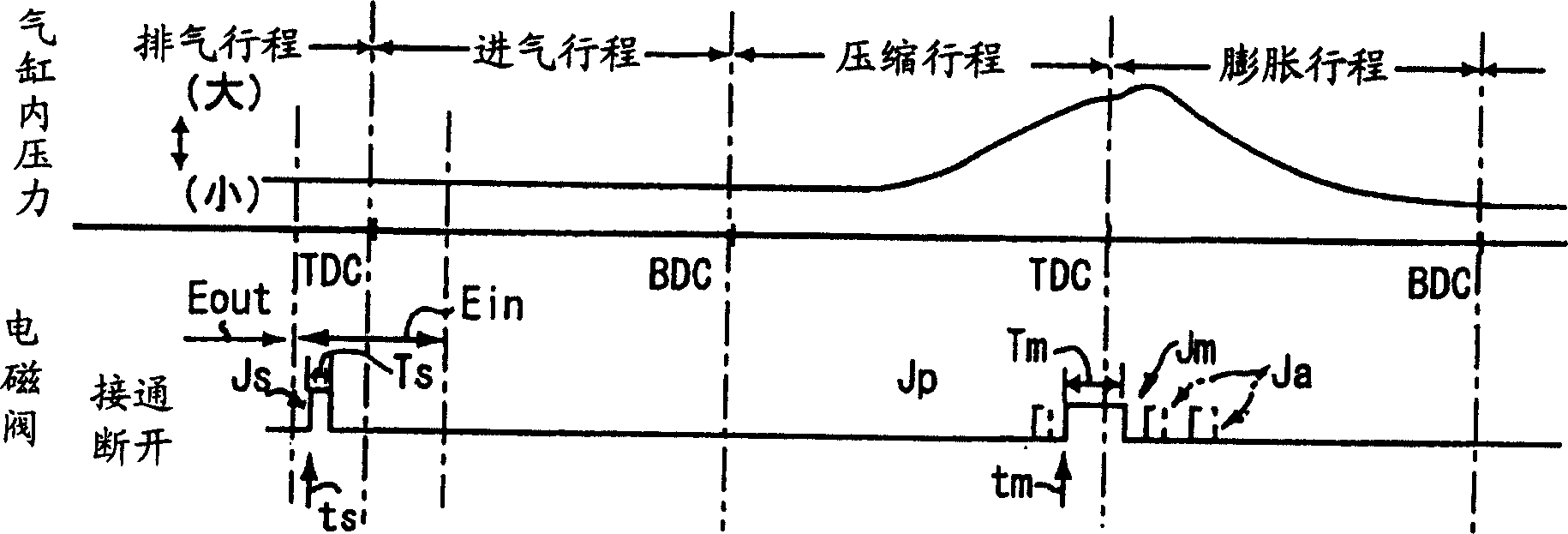

[0040] In the lower part of the cylinder head 4, a fuel injection valve 8 is installed facing the combustion chamber 7, and an intake p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com