Preparation method of in-situ doped and modified nickel cobalt manganese lithium oxide positive material

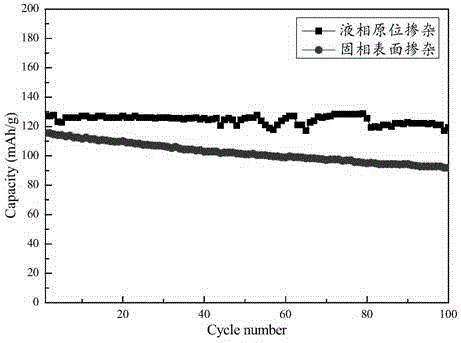

A nickel-cobalt-manganese-lithium oxide and in-situ doping technology, which is applied in the direction of positive electrodes, active material electrodes, battery electrodes, etc., can solve problems such as structural instability, battery cycle performance degradation, and limited improvement range, and achieve cycle performance improvement , saving cost and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

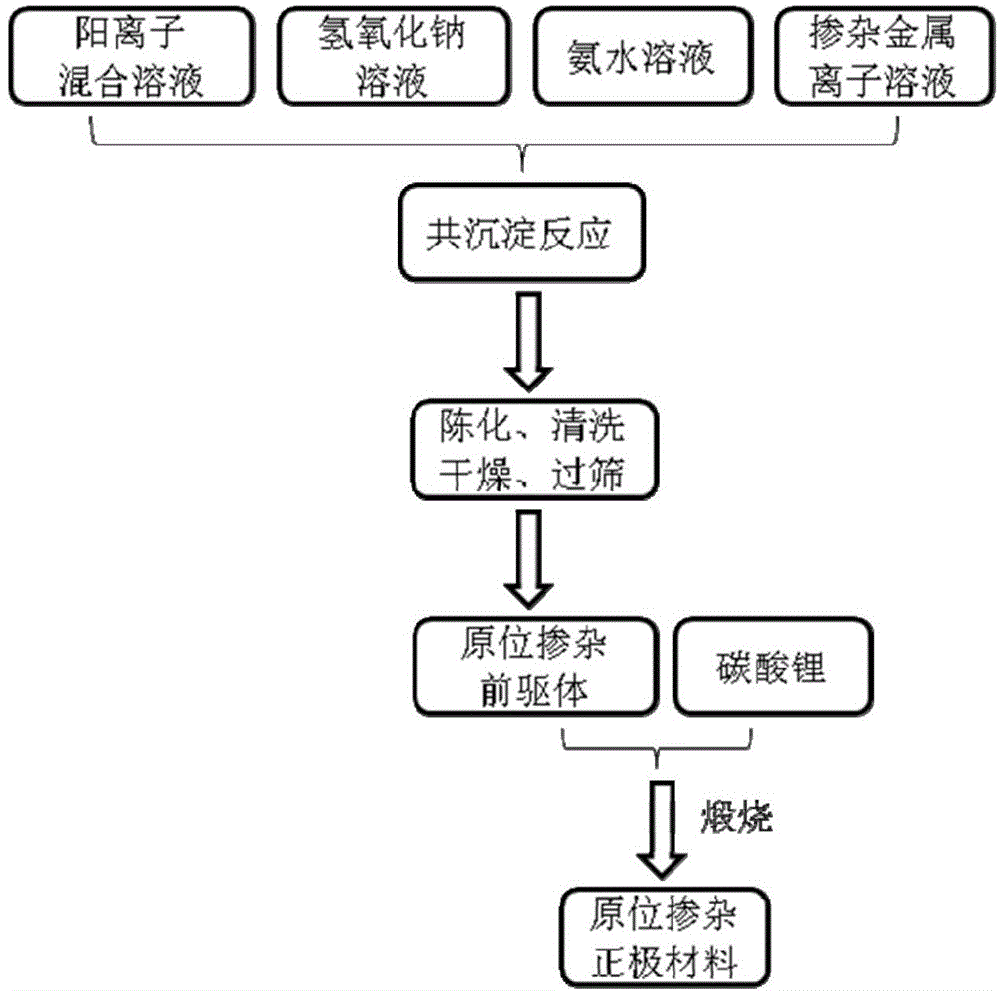

Method used

Image

Examples

Embodiment 1

[0031] 1) The soluble salts of nickel, cobalt, and manganese are configured into 10L 2.3mol / L nickel, cobalt, and manganese metal cation-containing mixed salt solutions (I) according to the molar ratio of nickel, cobalt, and manganese elements of 5:2:3 , configure 10L of 6mol / L NaOH solution and 2.2L of 12mol / L ammonia water and mix the two to obtain a mixed solution (II);

[0032] 2) Prepare 20 g of titanyl sulfate into 5 L of titanyl sulfate solution, add 40 ml of concentrated hydrochloric acid, stir, add 10 g of sodium lactate, and stir for 2 hours at a constant speed to obtain a mixed solution containing titanium metal (Ⅲ);

[0033] 3) Pump the mixed salt solution (I), NaOH and ammonia water mixed solution (II) and metal titanium-containing mixed solution (III) prepared in step 1) and step 2) into the reaction kettle at the same time, and control the NaOH and ammonia water The flow rate of the mixed solution makes the pH of the mixed reaction solution in the reactor be 11....

Embodiment 2

[0036] 1) the soluble salt of nickel, cobalt, manganese is configured into 10L 2mol / L nickel, cobalt, manganese metal cation mixed salt solution (I) according to the molar ratio of nickel, cobalt, manganese element is 5:2:3, Configure 12L of 4mol / L NaOH solution and 2L of 12mol / L ammonia water and mix the two to obtain a mixed solution (II);

[0037] 2) Prepare 43 g of aluminum nitrate as 4.5 L of aluminum nitrate solution, add 42 g of disodium ethylenediaminetetraacetate to it, and stir at a constant speed for 1 hour to obtain a mixed solution (III) containing metal aluminum;

[0038] 3) Pump the mixed salt solution (I), the mixed solution of NaOH and ammonia water (II) and the mixed solution containing metal aluminum (III) prepared in step 1) and step 2) into the reaction kettle at the same time, and control the concentration of NaOH and ammonia water. The flow rate of the mixed solution makes the pH of the mixed reaction solution in the reactor be 11.5, the stirring speed o...

Embodiment 3

[0041] 1) the soluble salt of nickel, cobalt, manganese is configured into 10L 2mol / L nickel, cobalt, manganese metal cation mixed salt solution (I) according to the molar ratio of nickel, cobalt, manganese element is 5:2:3, Configure 26L of 2mol / L NaOH solution and 2.5L of 10mol / L ammonia water and mix the two to obtain a mixed solution (II);

[0042] 2) 7g of magnesium nitrate and 17g of aluminum nitrate are configured as a mixed solution of 4L of magnesium nitrate and aluminum nitrate, 26g of disodium edetate is added thereto, and stirred at a constant speed for 0.5h to obtain a mixed solution containing metal magnesium and aluminum (Ⅲ );

[0043] 3) Pump the mixed salt solution (I), the mixed solution of NaOH and ammonia water (II) and the mixed solution (III) containing metal magnesium and aluminum into the reaction kettle at the same time, and control the NaOH and The flow rate of the ammonia water mixed solution makes the pH of the mixed reaction solution in the reacto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com