Carbon coated granularity controllable spherical lithium ferric phosphate composite positive pole material and preparation thereof

A composite cathode material, a technology of lithium iron phosphate, which is applied in the field of material preparation, carbon-coated particle size controllable spherical lithium iron phosphate composite cathode material, and can solve the problems of complex preparation process, large particle size of lithium iron phosphate, and difficulty. , to achieve uniform particle size distribution, adjustable particle size, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

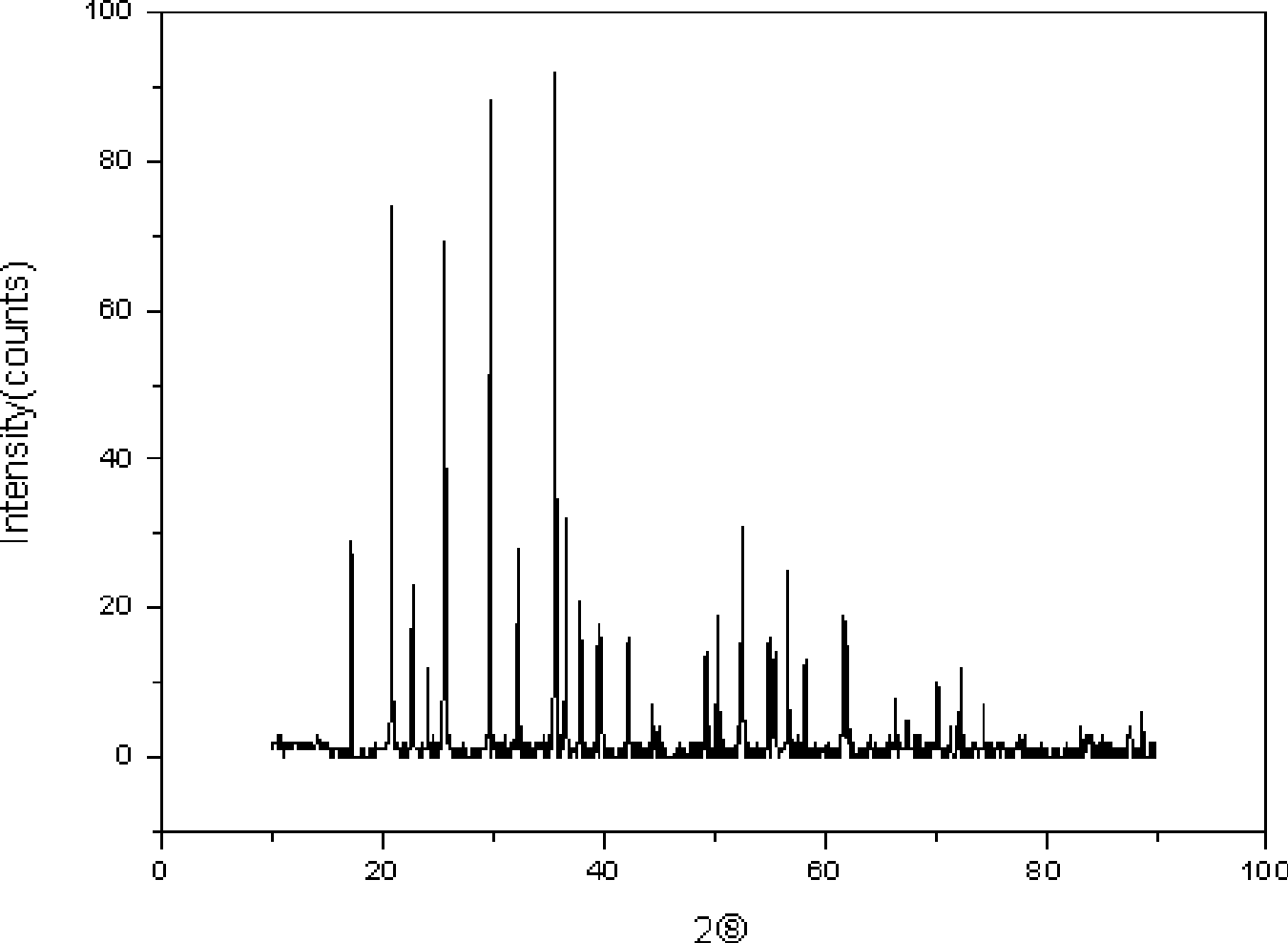

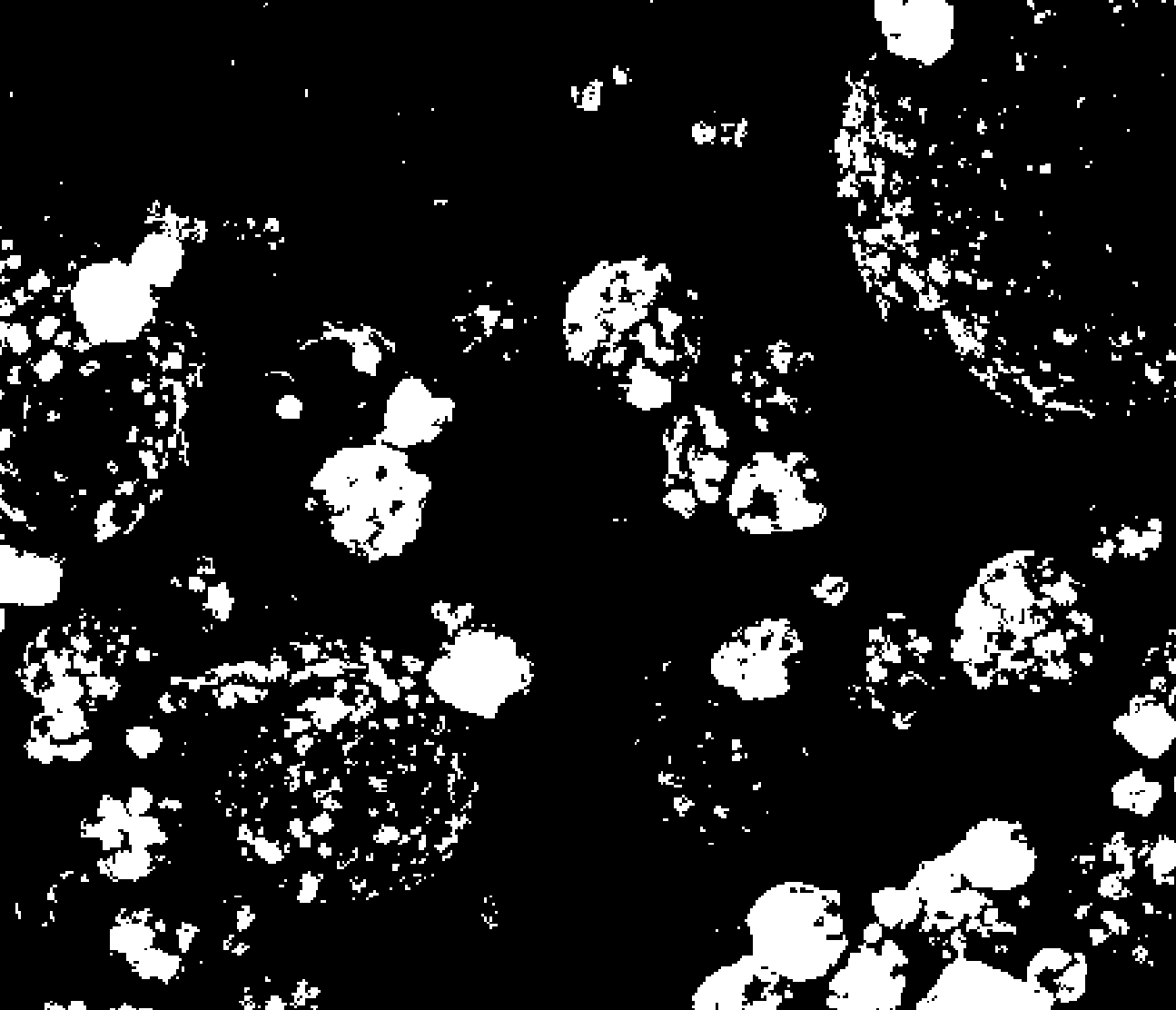

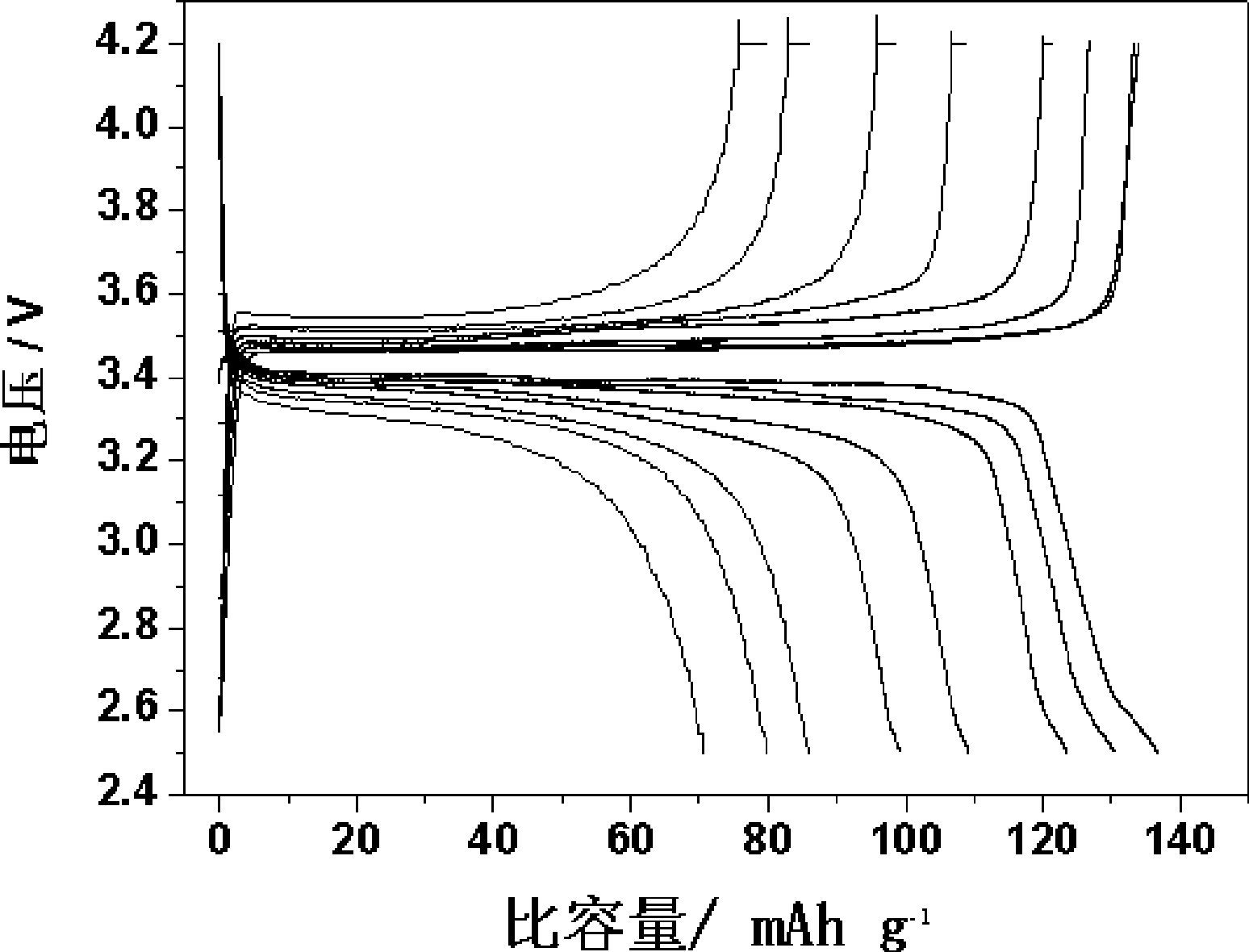

Embodiment 1

[0035] Weigh 798.45g Fe 2 o 3 , 1039.3gLiH 2 PO 4 , 213.9g of sucrose, and 8206.75g of distilled water were placed in a stirring mill, and stirred and ground for 24 hours at 400 rpm to obtain a yellow suspension with a solid content of 20%, which was the precursor solution; the precursor solution was continuously stirred, Under the condition of inlet pressure 0.8MPa, feed rate 2L / min, carry out spray drying, spray inlet temperature is 200 ℃, outlet temperature is 70 ℃, obtains light yellow precursor powder; Precursor powder is put into nitrogen (gas flow rate 2L / min) in the protected pusher kiln, the temperature was raised at a rate of 2°C / min, and the temperature was pre-decomposed at 400°C for 5 hours, and then the temperature was raised to 800°C at the same rate, and then heat-preserved and calcined for 12 hours, and the sample was cooled with the furnace to At room temperature, the carbon-coated spherical lithium iron phosphate composite positive electrode material with...

Embodiment 2

[0038] Weigh 798.45g Fe 2 o 3 , 1039.3gLiH 2 PO 4 , 213.9g sucrose, and 11622g distilled water were placed in the stirring mill, and stirred and ground for 20 hours with 400 rev / min to obtain a yellow suspension with a solid content of 15%, that is, the precursor solution; the precursor solution was continuously stirred, and the Inlet pressure 1.0MPa, spray drying under the condition of feed rate 1L / min, spray inlet temperature is 180 ℃, outlet temperature is 80 ℃, obtains pale yellow precursor powder; Precursor powder is put into argon (gas Flow rate 2L / min) protected pusher kiln, temperature was raised at a rate of 3°C / min, pre-decomposed at 400°C for 5 hours, and then heated to 800°C at the same rate, and then calcined for 12 hours, and the sample was cooled with the furnace to At room temperature, the carbon-coated spherical lithium iron phosphate composite positive electrode material with controllable particle size can be obtained.

[0039] Take by weighing the LiFePO...

Embodiment 3

[0041] Weigh 808.04g Fe(NO 3 ) 3 9H 2 O, 209.8gLiOH·H 2 O, 576.47g85%H 3 PO 4 , 233.2g of glucose and starch, and 7310g of water were placed in a stirring mill, and stirred and ground for 15 hours at 200 rpm to obtain a yellow suspension with a solid content of 25%, that is, the precursor solution; the precursor solution was continuously stirred , under the conditions of inlet pressure 0.6MPa and feed rate 0.5L / min, spray drying is carried out, the spray inlet temperature is 220°C, and the outlet temperature is 60°C to obtain light yellow precursor powder; put the precursor powder into nitrogen In a rotary kiln protected by hydrogen and hydrogen (gas flow rate 2L / min), the temperature was raised at a rate of 5°C / min, pre-decomposed at 360°C for 8 hours, and then heated to 700°C at the same rate, and then calcined for 18 hours. The furnace was cooled to room temperature, and the carbon-coated spherical lithium iron phosphate composite cathode material was obtained. The pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com