Production of NDI-polyurethane microporous elastomer

A technology of microcellular elastomer and polyurethane, which is applied in the field of preparation of polyurethane microcellular elastomer, can solve the problems of insufficient weather resistance and hydrolysis stability of NDI-based microcellular elastomer, and achieve the effect of optimizing hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

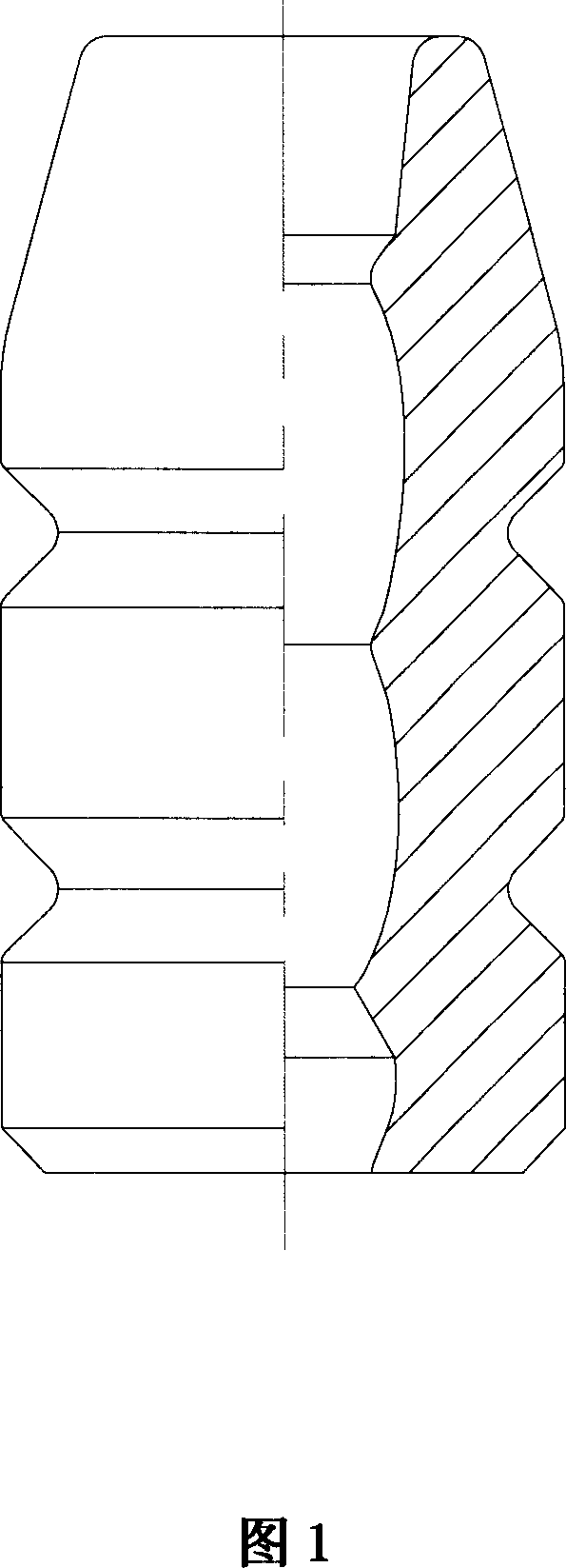

Image

Examples

Embodiment 1

[0030] Poly(trimethylolpropane-2-methyl-1.3propylene glycol-1.4-butanediol adipate) ester with a molecular weight of 3000 and a functionality of 2.3 reacts with NDI at 120-140°C to obtain -NCO content 8.2% prepolymer. The crosslinking agent component is mainly polyester, and the auxiliary component includes foaming agent, catalyst, surfactant, etc., wherein the auxiliary component accounts for 15% of the total crosslinking agent; using a low-pressure foaming machine, according to isocyanate The ratio of the index is 100%, mix the prepolymer and crosslinking agent components, inject the reaction material liquid into the mold at 65-90°C to make the microporous elastomer test piece, demould after 30min, and then put it into the oven at 110°C Post-cure for 15 hours.

[0031] The test piece prepared according to this embodiment was placed at room temperature for one week, and then its mechanical properties and hydrolysis resistance were measured.

[0032] Test mechanical properti...

Embodiment 2

[0036] Poly(1,2-dimethylpropanediol-1.4-butylene glycol-ethylene glycol adipate) ester with a molecular weight of 2000 reacts with NDI at 120-140°C to obtain a prepolymer with a -NCO content of 6.50%. body. The crosslinking agent component is mainly polyester, and the auxiliary component includes foaming agent, catalyst, surfactant, etc., wherein the auxiliary component accounts for 15% of the total crosslinking agent; using a low-pressure foaming machine, according to isocyanate The ratio of the index is 100%, mix the prepolymer and crosslinking agent components, inject the reaction material liquid into the mold at 65-90°C to make the microporous elastomer test piece, demould after 30min, and then put it into the oven at 110°C Post-cure for 15 hours.

[0037] The test piece prepared according to this embodiment was placed at room temperature for one week, and then its mechanical properties and hydrolysis resistance were measured.

[0038] Test mechanical properties with com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com