Method and device for measuring oil content of oil well produced liquid

The technology of a metering device and metering method is applied in the direction of volume flow measuring device, measuring device, volume metering, etc., which can solve the problems of long time for oil well metering, failure to meet metering requirements, and high labor intensity, so as to improve metering accuracy, The effect of reducing measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

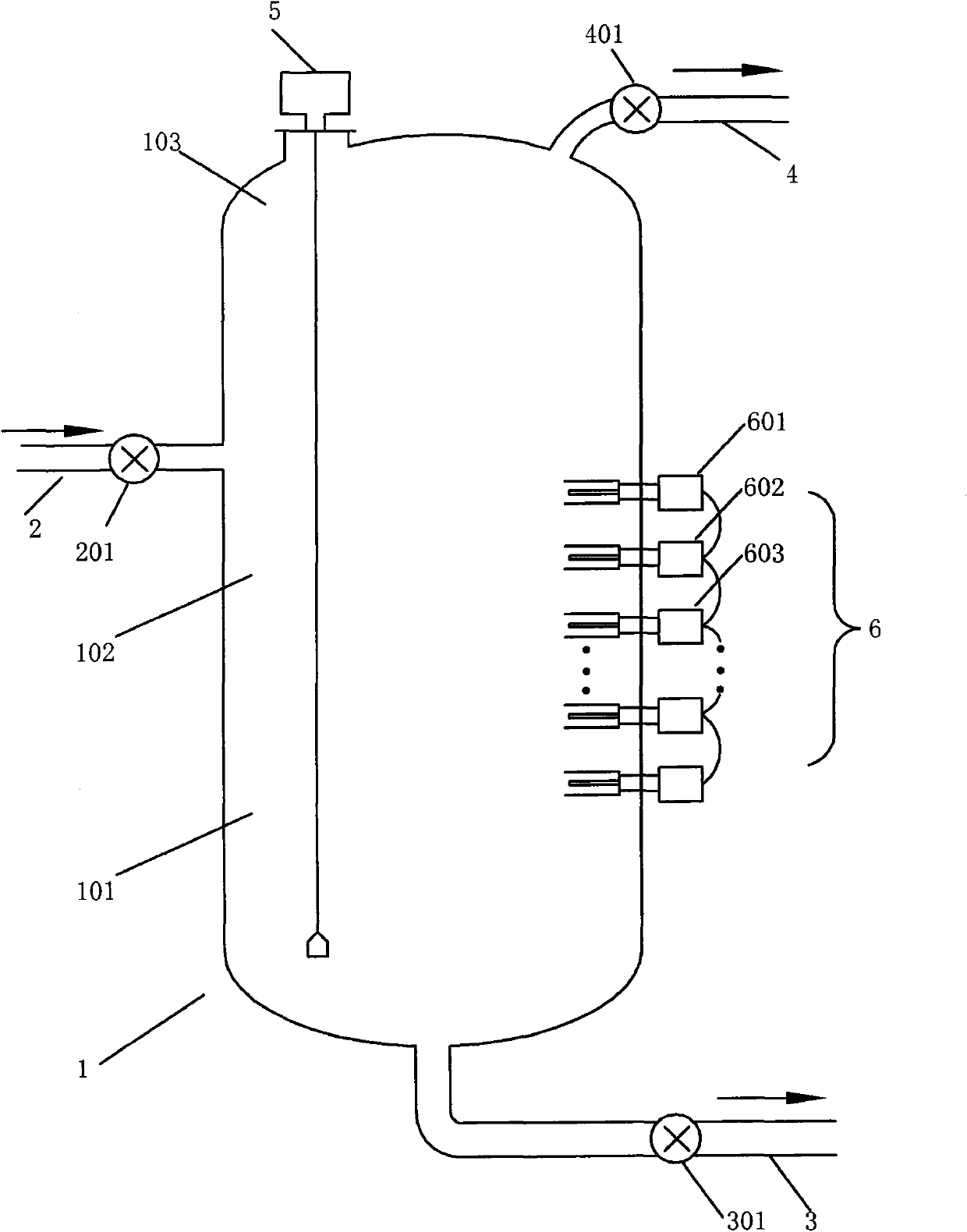

[0032] like figure 1 As shown, an oil well output liquid oil content metering device is provided with a vertical separation tank 1, and an oil well output liquid input pipeline 2 and a liquid output pipeline are respectively arranged on the upper part, the lower part and the top of the separation tank 1. 3. The gas output pipeline 4 is provided with a liquid inlet valve 201, a liquid discharge valve 301, and an exhaust valve 401 on the oil well output fluid input pipeline 2, the liquid output pipeline 3, and the gas output pipeline 4 respectively; The tank is also provided with a liquid level meter 5 for monitoring the liquid level, which is characterized in that: the separation tank 1 is also provided with several oil-water component measuring instrument probes 6, which can successively measure the horizontal liquid level layer where the probes are located. For the measurement of oil content or water content, the probe 6 of the oil-water composition measuring instrument is mo...

Embodiment 2

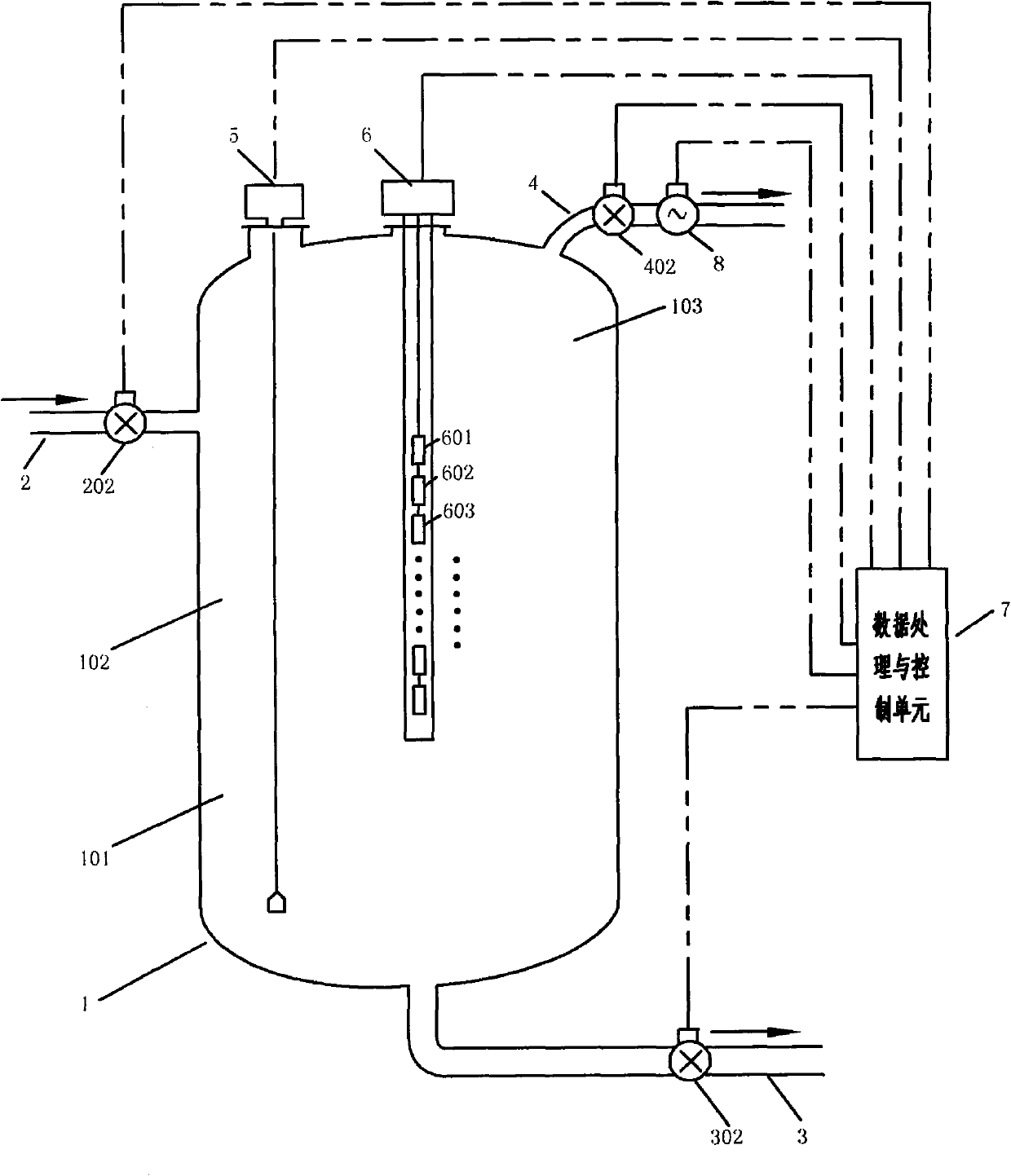

[0037] like figure 2 As shown, a metering device for oil content of oil well output fluid is characterized in that the probes 601, 602, 603, etc. of the oil-water composition measuring instrument are mounted on the top of the separation tank 1, and Features are the same as in Example 1.

Embodiment 3

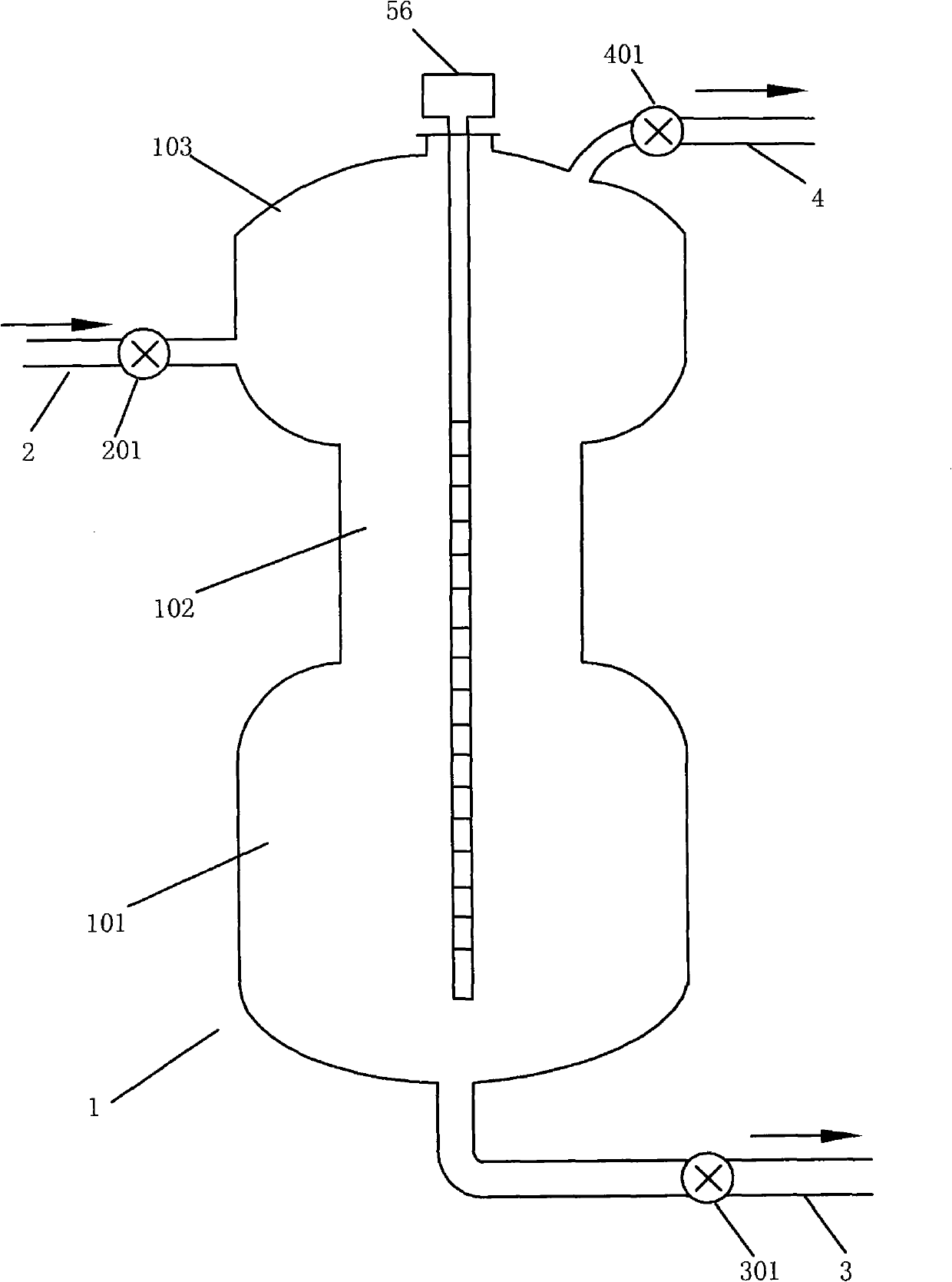

[0039] A metering device for oil content of oil well produced fluid, characterized in that the probes 601, 602, 603, etc. of the oil-water composition measuring instrument are integrated with the liquid level meter 5 into a device 56, and The top is mounted on the separation tank 1, and other features are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com