Electrically-driven symmetric plunger gas micro flow standard device

A flow standard device, plunger-type technology, applied in the field of electric-driven symmetrical plunger-type gas micro-flow standard device, can solve the problems of reduced measurement accuracy, difficulty in realizing, changing gas, etc., and achieve reliable work, adjustable pressure, and fluctuation small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

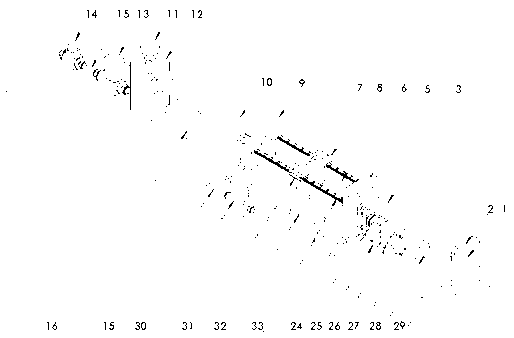

[0018] Such as figure 1 , figure 2 As shown, the right bracket 2, the transmission end plate 5, the transmission bracket 9, the buffer tank 12, the detected flowmeter 13, the flow controller 14, the pressure transmitter 16 and the motor bracket 25 are respectively fixed on the base plate 29; the right cylinder 3 It is fixed between the right bracket 2 and the transmission end plate 5, and rubber gaskets are used to ensure the tightness between the connections. There is an air inlet 1 on the right bracket 2 to communicate with the right cylinder 3, and the pressure is stable and adjustable. The air inlet 1 enters the inside of the right cylinder block 3 and serves as a flow source for gas metering.

[0019] Such as figure 1 , figure 2 As shown, the transmission end plate 5 is used as the connection object of the right cylinder 3 and the fixed side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com