Crude-oil automatic continuous measuring device

A metering device and automatic technology, applied in surveying, wellbore/well components, earthwork drilling, etc., can solve the problems of single metering device, low metering accuracy, and small adaptability range, and achieve high metering accuracy, large metering range, good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

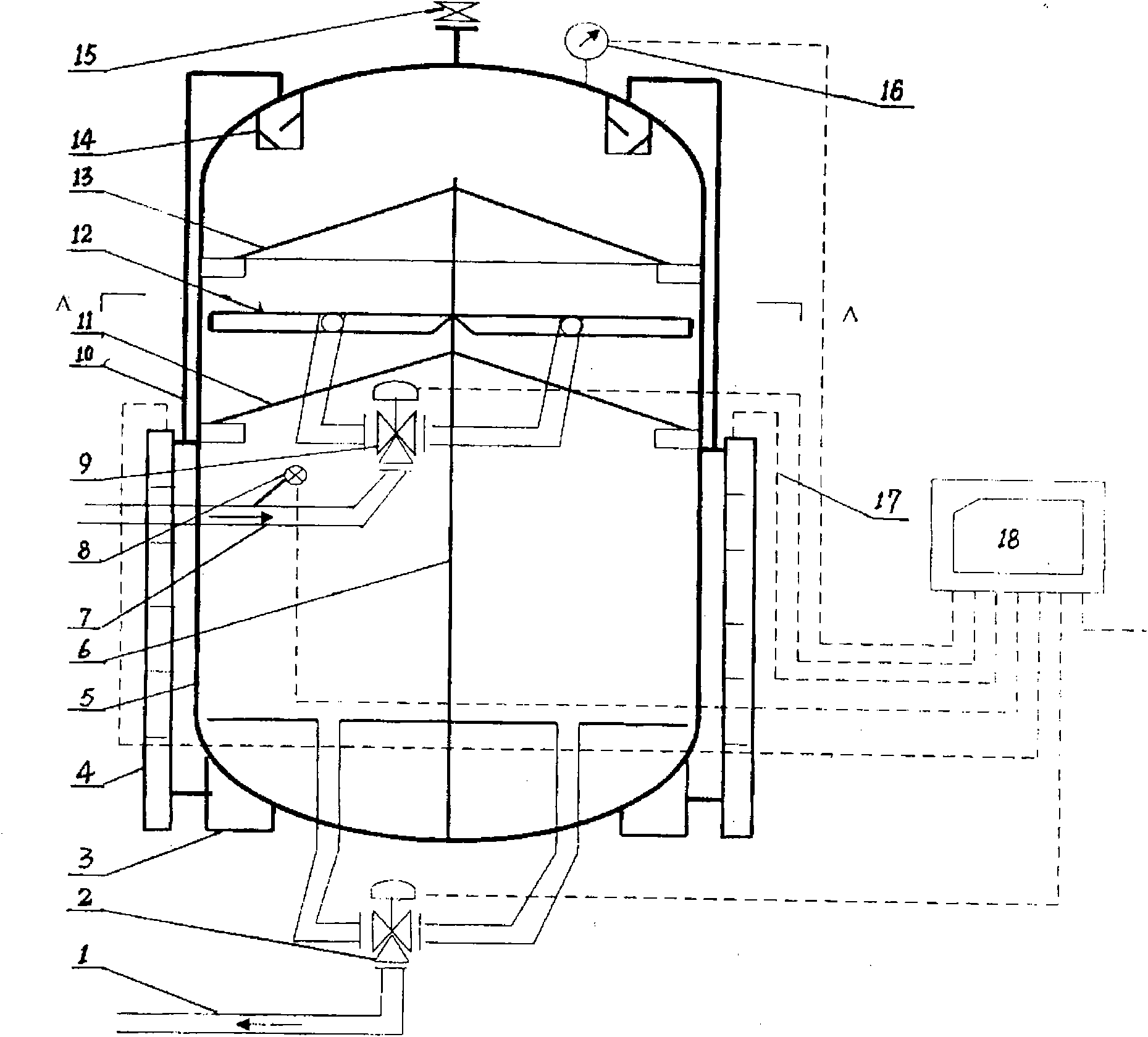

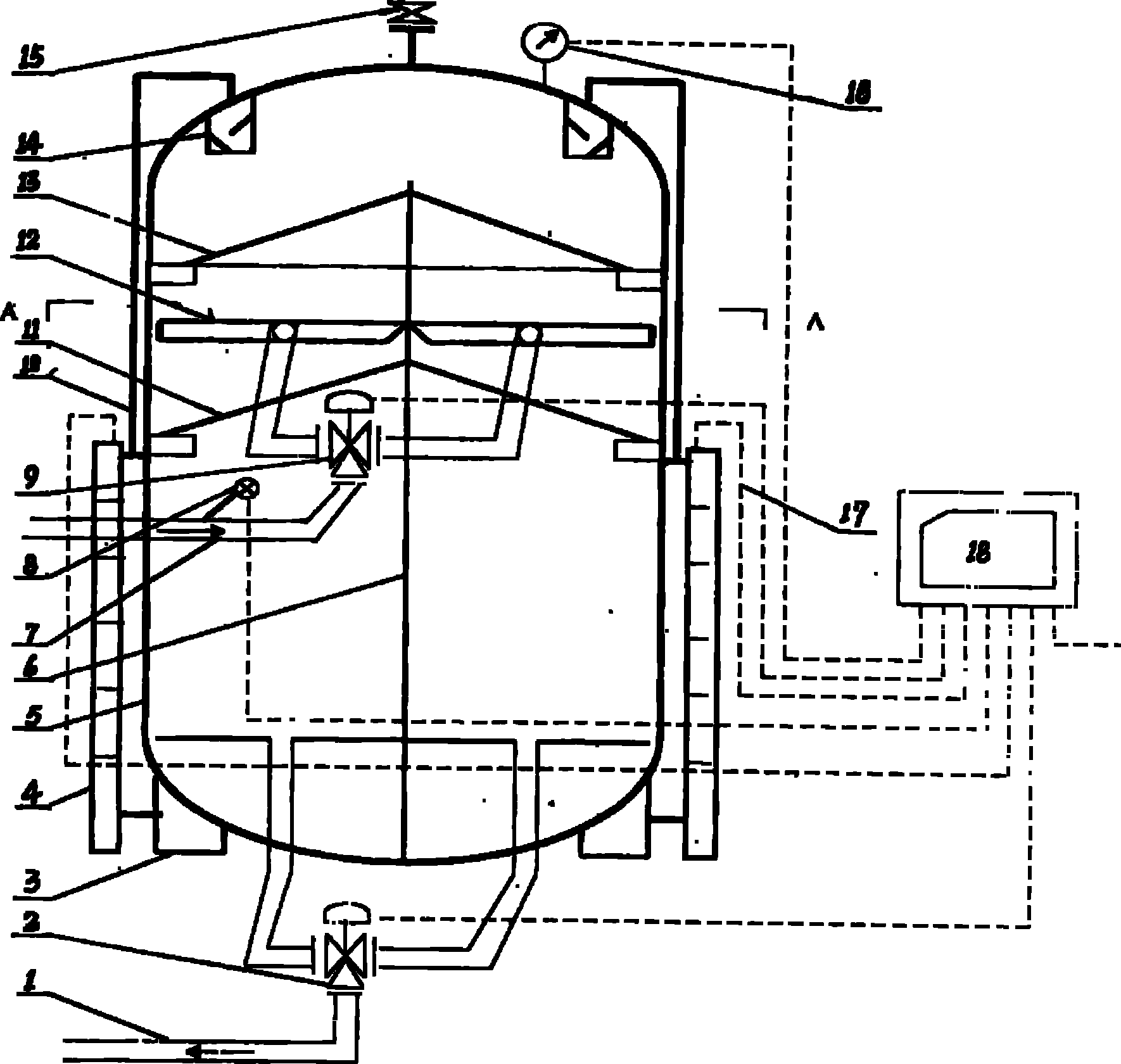

[0020] Example 1. Automatic metering of oil wells with high gas-oil ratio and large associated gas volume

[0021] If the metering station where the metering device is applied has a high gas-oil ratio and a large gas production, a work cylinder in the separator can be used to measure oil and gas automatically. The metering principle is the same as that of glass tube oil metering. For example, the left working cylinder can be used for measurement. During the measurement, the intelligent control system controls the imported electric three-way valve 9 to be in a conducting state to the left working cylinder, and then controls the outlet electric three-way valve 2 to be in a conducting state to the left working cylinder, and the right working The cylinder is not connected to the external inlet and outlet pipelines, the gas is gradually separated from the crude oil, and the crude oil in the left working cylinder is pressed away from the outlet pipeline. When the liquid level in the ...

example 2

[0022] Example 2. Automatic metering of oil wells with low gas-oil ratio, small amount of associated gas or no associated gas

[0023] For oil wells with low gas-oil ratio, small amount of associated gas or no associated gas, the two working cylinders in the separator need to work at the same time. Since the separator cannot realize the normal pressure liquid level emptying, the metering device can be filled with nitrogen in advance, which is used for the pressure liquid level during the metering operation.

[0024] The oil well is poured into the metering device, and the intelligent control system 18 issues commands to the import and export three-way valves according to the detected liquid levels of the two working barrels. When the inlet three-way valve 9 is connected to the left working cylinder under the control of the control system, and the outlet three-way valve 2 is connected to the right working cylinder, the liquid level in the left working cylinder starts to rise, n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com