Doped small-particle size lithium nickel cobalt manganese oxide positive electrode material and precursor thereof and preparation methods of doped small-particle size lithium nickel cobalt manganese oxide positive electrode material and precursor

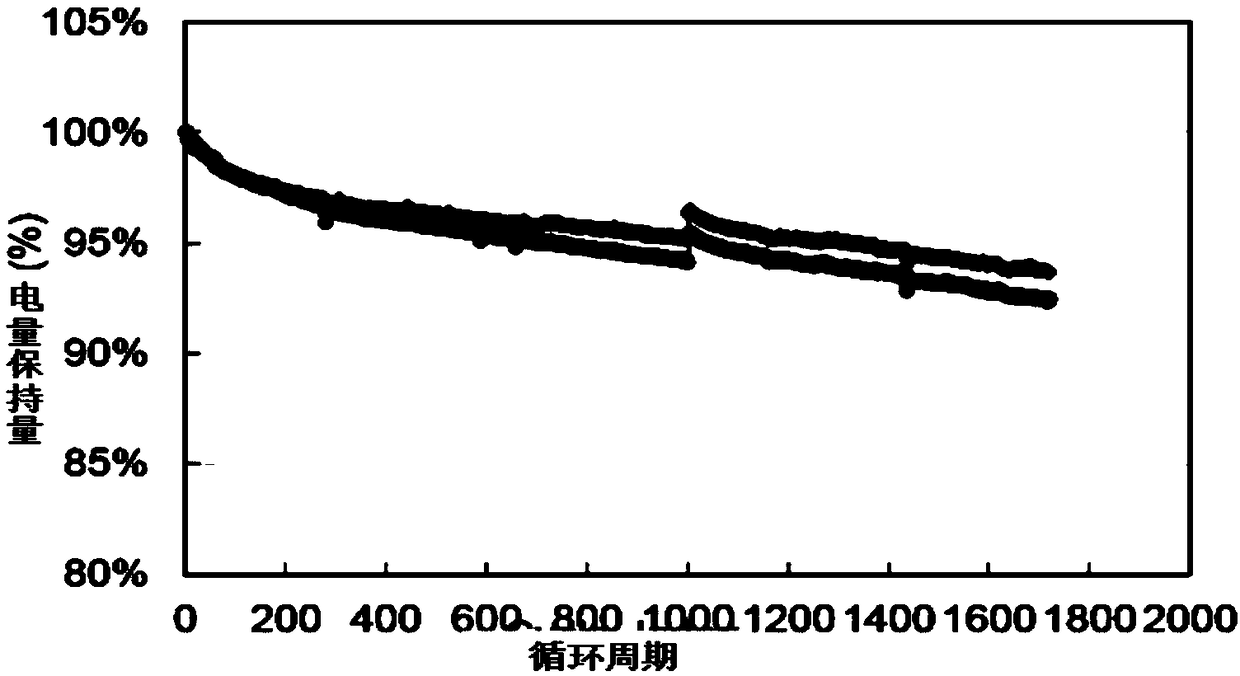

A technology of nickel-cobalt lithium manganese oxide and positive electrode materials, which is applied to battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of battery cycle performance degradation and structural instability, and achieve cycle performance improvement, cost saving, and simplification. The effect of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 0.1Zr / Ni 1 / 3 Co 1 / 3 Mn 1 / 3 (OH) 2 Preparation:

[0030] (1) According to the molar ratio of Ni:Co:Mn 1:1:1, add 0.1% of the total mass of the nickel-cobalt-manganese ternary precursor to prepare a mixture of nickel-cobalt-manganese-zirconium sulfate with a concentration of 1.5mol / L Aqueous solution, prepare a sodium hydroxide aqueous solution with a concentration of 8mol / L, and prepare an ammonia solution with a concentration of 8mol / L;

[0031] (2) Add a mother liquor with an ammonia concentration of 1.0-2g / L and a pH of 11.0-11.5 to the reactor, and make the mother liquor 60% of the reactor volume;

[0032] (3) Pour 1L / min of nitrogen into the sealed reactor, turn on the stirring, and rotate at 140r. Use the prepared sodium hydroxide solution and ammonia solution in step (1) to continuously pump into the reactor for 15 minutes, during which the metal mixture Turn off the pump, turn off the ammonia and alkali pump; turn on the metal mixture pump, pump the prepared metal salt...

Embodiment 2

[0041] 0.08Mg / Ni 0.5 Co 0.2 Mn 0.3 (OH) 2 Preparation:

[0042] (1) According to the molar ratio of Ni:Co:Mn of 5:2:3, add 0.08% of the total mass of the nickel-cobalt-manganese ternary precursor to prepare a mixed aqueous solution of nickel-cobalt-manganese-magnesium sulfate with a concentration of 1.8mol / L , Prepare an aqueous sodium hydroxide solution with a concentration of 6 mol / L, and prepare an aqueous ammonia solution with a concentration of 10 mol / L;

[0043] (2) Add a mother liquor with an ammonia concentration of 2.5-3.0 g / L and a pH of 11.5-12.0 to the reactor, and make the mother liquor 80% of the reactor volume;

[0044] (3) Pour nitrogen 0.7L / min into the sealed reactor, turn on the stirring, and rotate at 380r / min. Use step (1) to continuously pump the sodium hydroxide aqueous solution and the ammonia aqueous solution into the reactor for 10 minutes. The metal mixture pump is turned off, and the ammonia alkali pump is turned off; the metal mixture pump is turned on, ...

Embodiment 3

[0052] 0.42Al / Ni 0.4 Co 0.2 Mn 0.4 (OH) 2 Preparation:

[0053] (1) According to the molar ratio of Ni:Co:Mn 4:2:4, add 0.42% of the total mass of the nickel-cobalt-manganese ternary precursor to prepare a nickel-cobalt-manganese-aluminum sulfate mixture with a concentration of 2.0mol / L Aqueous solution, prepare a sodium hydroxide aqueous solution with a concentration of 8mol / L, and prepare an ammonia solution with a concentration of 8mol / L;

[0054] (2) Add a mother liquor with an ammonia concentration of 0.5-1.0 g / L and a pH of 10.5-11.0 to the reactor, and make the mother liquor 40% of the reactor volume;

[0055] (3) Pour 1.5L / min of nitrogen into the sealed reactor, turn on the stirring at a speed of 200r / min, and use the prepared sodium hydroxide solution and ammonia solution in step (1) to continuously pump into the reactor for 5 minutes. The metal mixture pump is turned off and the ammonia alkali pump is turned off; the metal mixture pump is turned on, and the metal salt sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com