Production method of calcium peroxide particles for slowly releasing oxygen

A technology of slow-release oxygen particles and calcium peroxide, applied in chemical instruments and methods, restoration of polluted soil, water/sludge/sewage treatment, etc. Lack of continuity and other problems, to achieve the effect of small secondary pollution, easy implementation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A preparation method of calcium peroxide slow-release oxygen particles, the specific preparation steps are as follows:

[0025] 1. Weigh a certain amount of polylactic acid particles, add it to dichloromethane with a mass-volume ratio of more than 2 times (that is, the ratio of the volume of dichloromethane to the mass of polylactic acid particles is greater than 2), and place it in a horizontal magnetic stirrer to stir To dissolve, the number of revolutions is 150rpm. After the polylactic acid is completely dissolved in dichloromethane, the stirring is stopped, and the solution is basically in a clear state.

[0026] 2. Weigh and add calcium peroxide powder equal to the mass of polylactic acid, and continue to stir and mix until the calcium peroxide is in a completely uniform suspension state.

[0027] 3. Volatilize the dichloromethane under constant stirring and ventilating conditions. When the dichloromethane gradually volatilizes until the mixture becomes a gel-lik...

specific Embodiment 1

[0029] Specific Example 1: The slow-release oxygen effect of preparing slow-release oxygen particles by mixing polylactic acid and calcium peroxide by equal mass

[0030] Weigh 7.2g of polylactic acid particles, add it into 500mL of dichloromethane, place it in a horizontal magnetic stirrer and stir to dissolve, the rotation speed is 150rpm. After the polylactic acid is completely dissolved in dichloromethane, the solution is basically in a clear state, weigh 7.2g of calcium peroxide powder, and continue to stir and mix, so that the calcium peroxide is in a completely uniform suspension state. After the dichloromethane gradually volatilized, the mixture was immediately filled into a tubular mold when it was in a gel-like semi-solid state, and formed into balls by extrusion and shearing. Place in a fume hood overnight to evaporate the dichloromethane completely. Finally, spherical calcium peroxide slow-release oxygen agent particles are obtained.

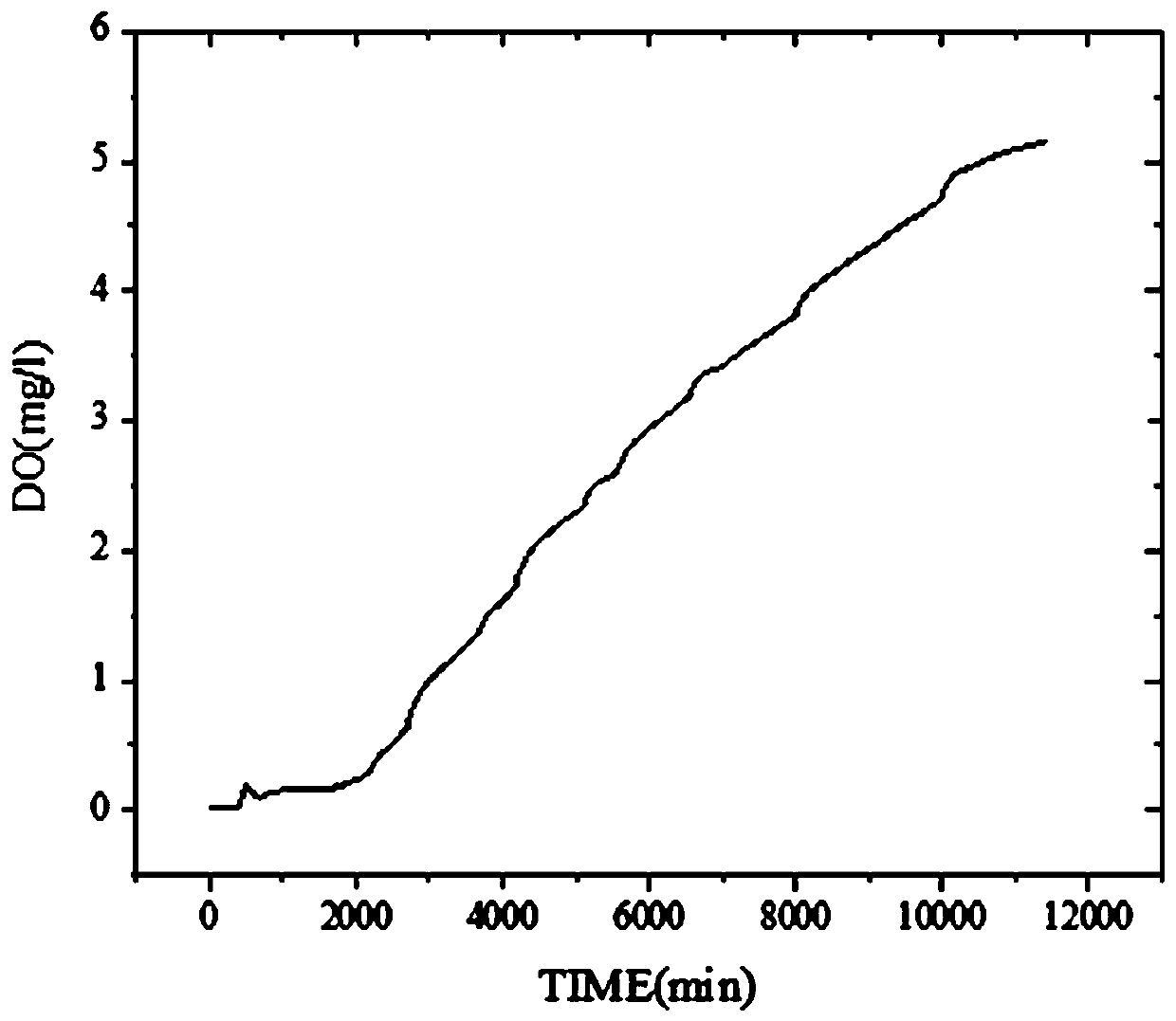

[0031] In a jar with a tota...

specific Embodiment 2

[0032] Specific Example 2: Maintain the aerobic state of activated sludge by using slow-release oxygen particles prepared by mass mixing polylactic acid and calcium peroxide

[0033] Prepare slow-release oxygen granules according to the above conditions of equal mass ratio, add 5g and 10g respectively to 100mL vials, the bottle is filled with 80mL activated sludge, the concentration of activated sludge is 3000mg / L, after adding slow-release oxygen granules Immediately stopper and seal. Among them, the dosage of 0g is used as a control, and the unsealed condition corresponds to the conventional aerobic shaking condition. The bacteria in the three groups of culture flasks were cultured in a shaker with a rotation speed of 150 rpm and a temperature of 30°C.

[0034] At the 72th hour of cultivation, the sludge in the group without slow-release oxygen agent was in a natural aerobic shaking culture, and the color of the sludge did not change significantly, while in the test groups ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com