High-efficiency coating stirring and mixing machine

A technology of stirring and mixing and stirring mechanism, which is applied in the direction of mixers with rotating stirring devices, mixers, mixer accessories, etc., can solve the problems of simultaneous mixing of difficult materials, difficult mixing of materials uniformly, low mixing efficiency, etc., and achieve improvement Stirring efficiency, convenient pick-and-place process, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

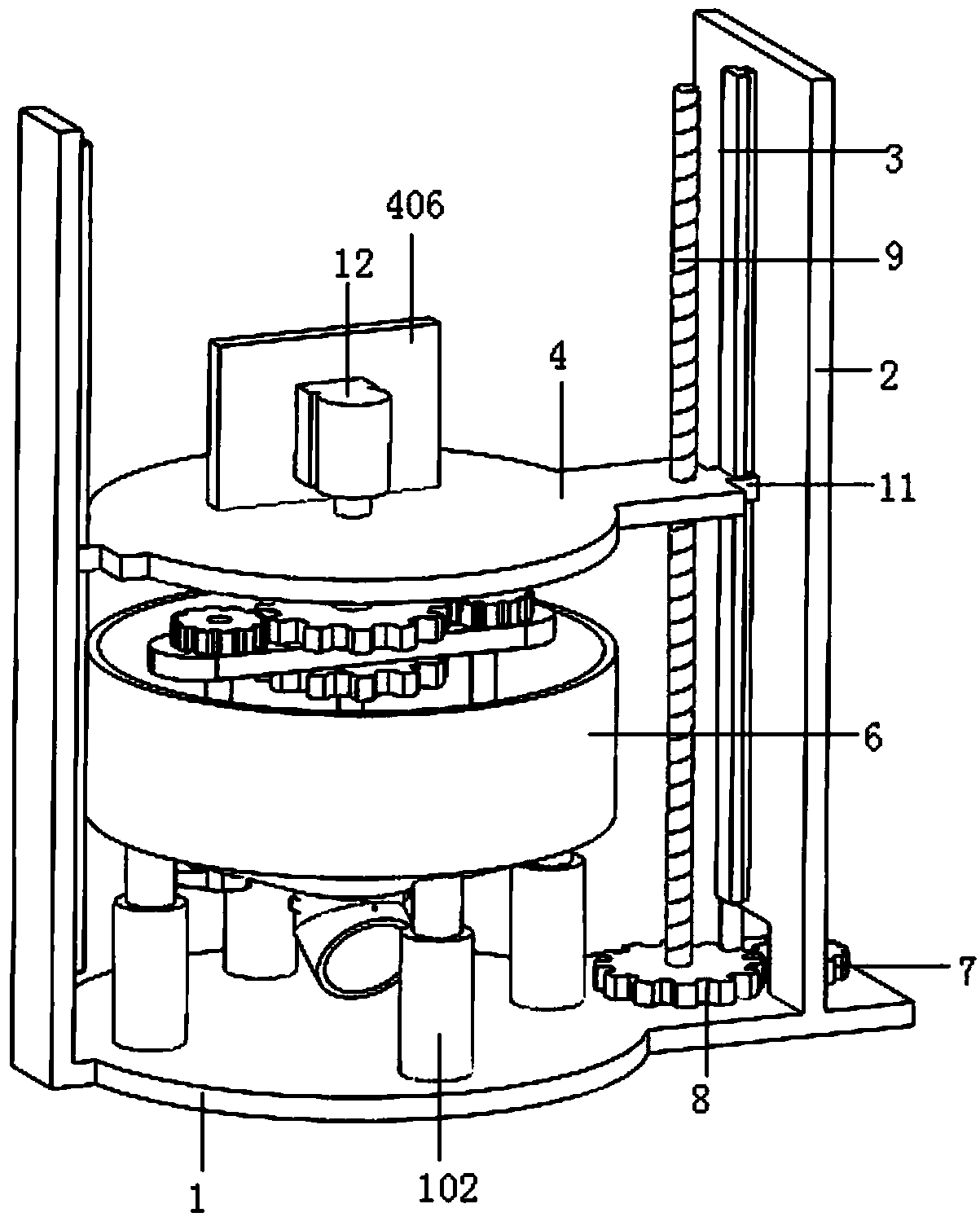

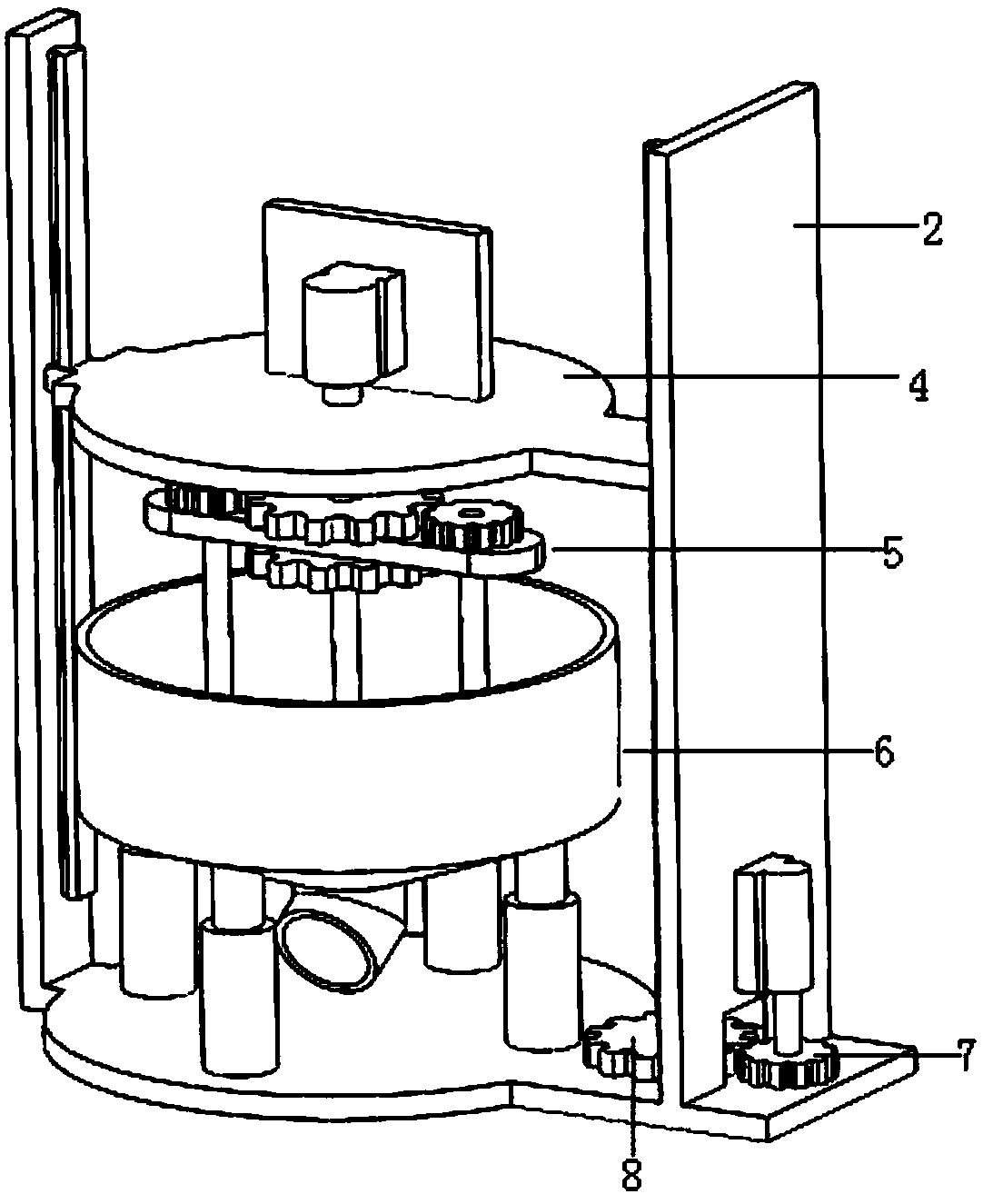

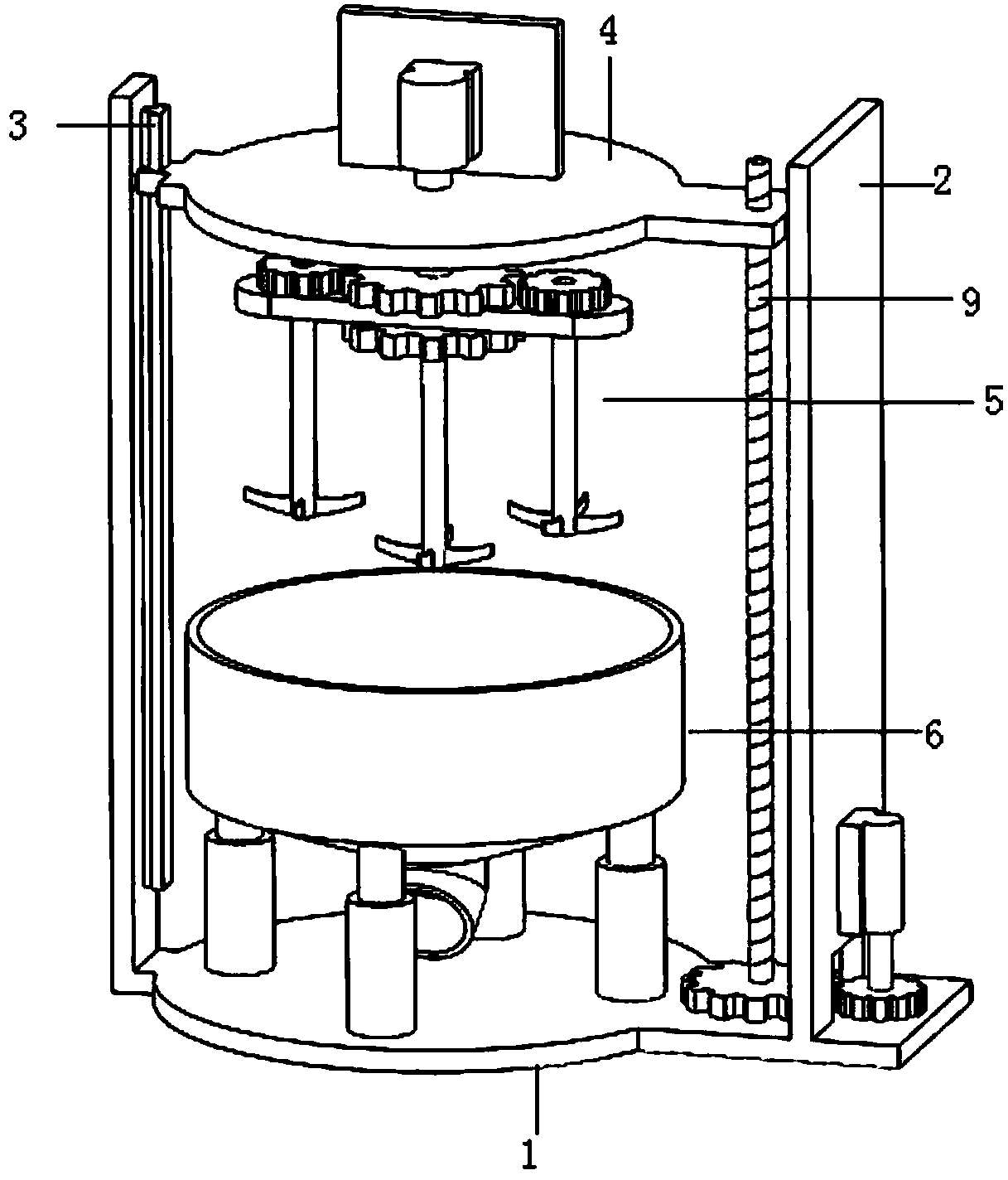

[0035] A high-efficiency paint mixing mixer, such as figure 1 , figure 2 with image 3 As shown, the fixed base 1 is included, and the two ends of the surface of the fixed base 1 are vertically fixed with two opposite positioning guide plates 2, and the inner surfaces of the two positioning guide plates 2 are relatively fixed with two opposite slide rails 3. A slide rail 3 is installed and fixed with a sliding support seat 4, and the lower end of the sliding support seat 4 is vertically fixed with a stirring mechanism 5;

[0036] A stirring tank 6 is installed and fixed on the surface of the fixing seat 1, and the stirring tank 6 is located directly below the stirring mechanism 5;

[0037] Such as Figure 4 with Figure 5 As shown, the first gear 7 and the second gear 8 are fixed on the fixed seat 1, the first gear 7 and the second gear 8 mesh, the second gear 8 is fixed with a lead screw 9, and the lead screw 9 passes through the sliding support The seat 4 drives the sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com