Ferric phosphate having micro-nano structure and preparation method thereof as well as lithium iron phosphate material

A technology of micro-nano structure and iron phosphate salt, applied in structural parts, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve problems such as difficult to achieve high tap density, high rate and high capacity, and achieve Controllable structure and shape, excellent performance and high tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparation of micro-nano structure basic ammonium iron phosphate and iron phosphate

[0035] Use ferrous sulfate as the iron source, configure 1mol / L ferrous sulfate aqueous solution, weigh ammonium dihydrogen phosphate into the aqueous solution according to the stoichiometric ratio, use sulfuric acid to adjust the pH of the obtained solution to 2, and keep the temperature at 20°C. Reacting for 0.5 hours under the condition of stirring rate of 300rpm;

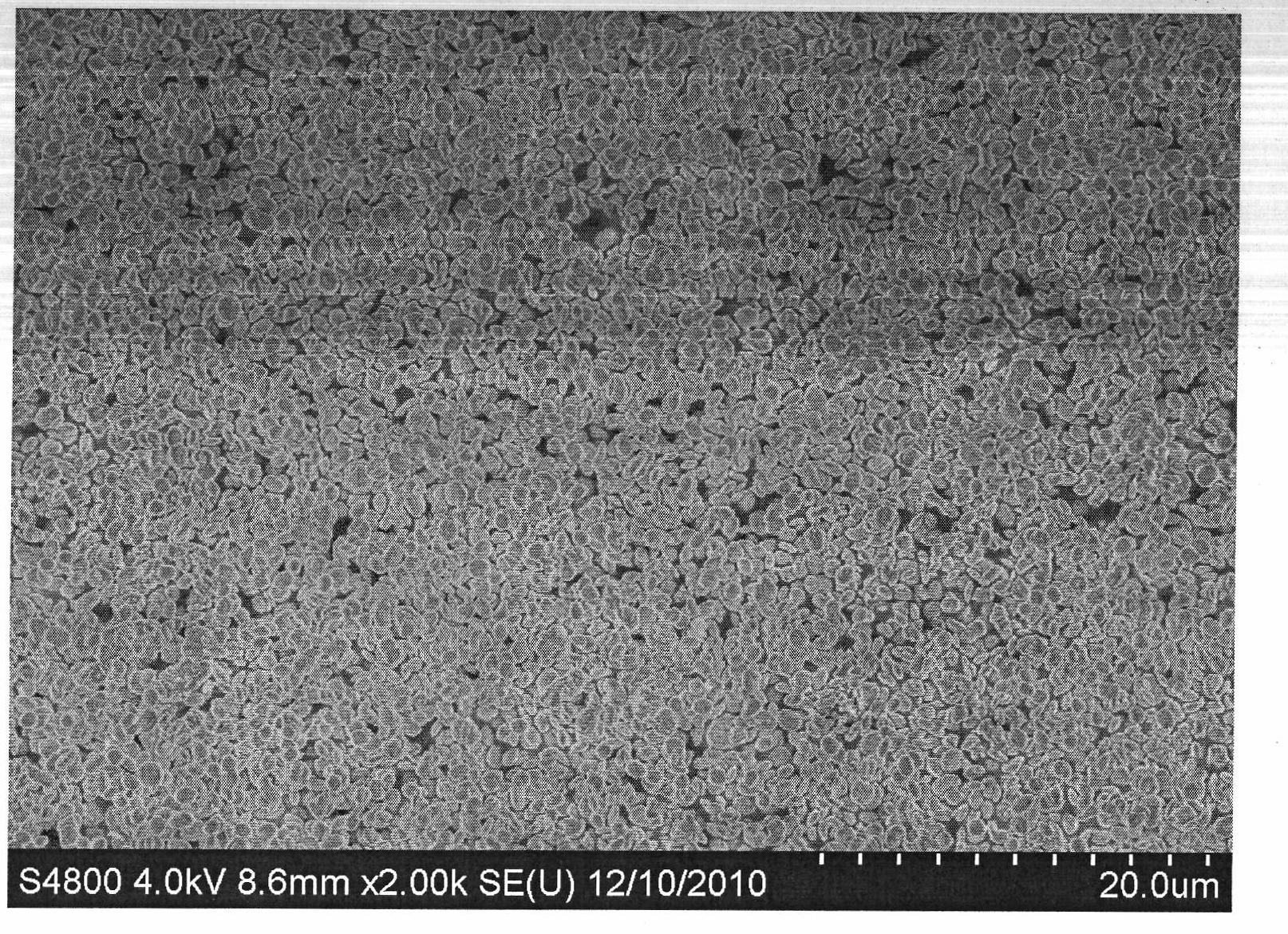

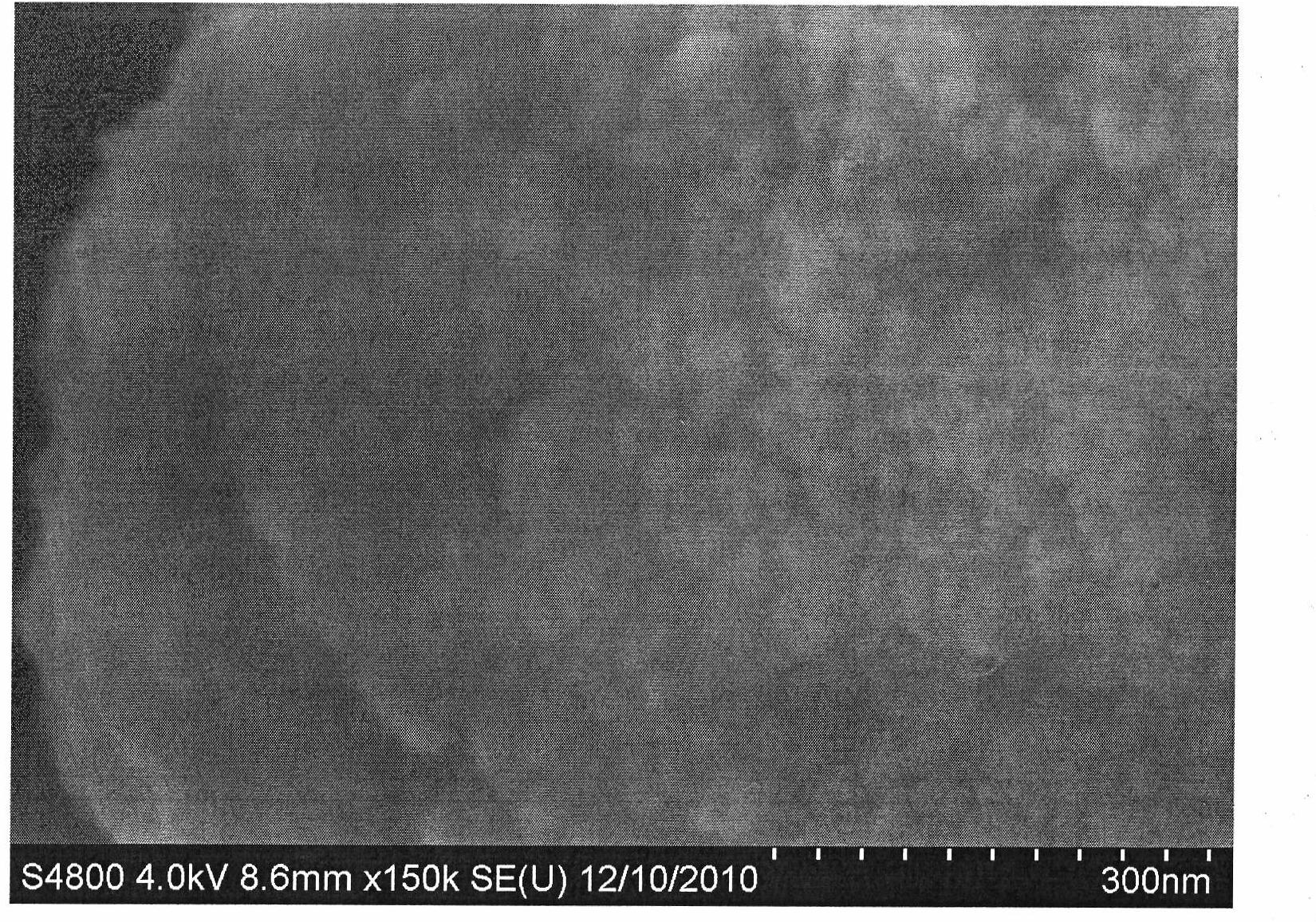

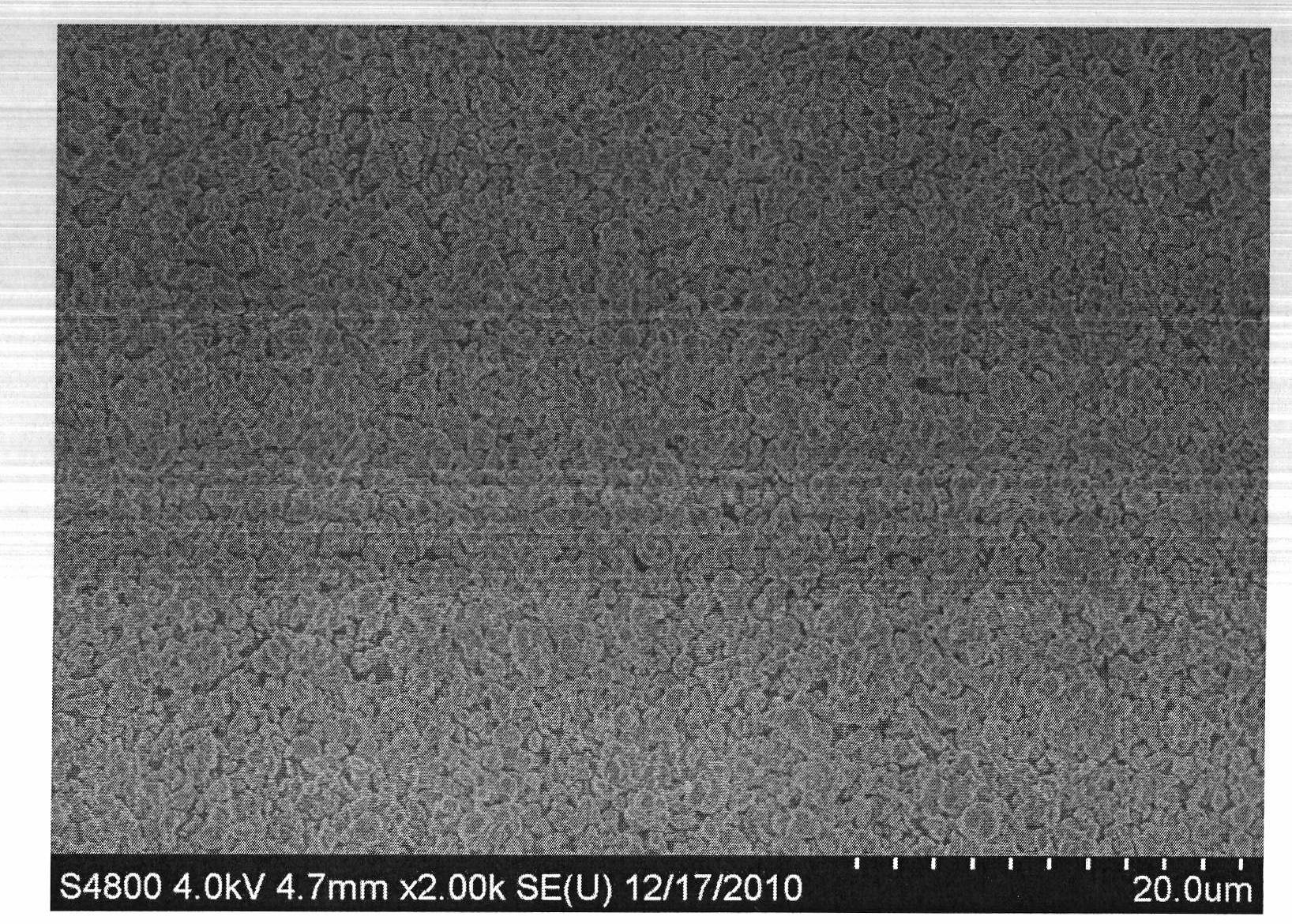

[0036] Control the stirring rate to 300rpm, measure the stoichiometric ratio of hydrogen peroxide, and add it dropwise to the mixed solution of ferrous sulfate and ammonium dihydrogen phosphate, and use ammonia water to adjust the system to PH = 2. After the addition, raise the temperature to 80°C to continue After reacting for 8 hours, it was centrifuged and washed until no sulfate group was detected with 30% barium chloride solution; the washed product was dried at 120°C for 4 hours to obtain a micronano-structure...

Embodiment 2

[0043] Prepare a 0.1mol / L ferrous nitrate solution, weigh diammonium hydrogen phosphate and add it to the aqueous solution according to the ferrous ion concentration and phosphate ion concentration of 0.8:1, use sulfuric acid to adjust the pH of the resulting solution to 3, and keep the temperature at 50 °C, reacted for 0.5 hours at a stirring rate of 500rpm; measure hydrogen peroxide with a stoichiometric excess of 10%, add it dropwise to the mixed solution of ferrous nitrate and diammonium hydrogen phosphate, and use ammonia water to adjust the system to PH=3, After the dropwise addition, keep the temperature at 50°C and continue the reaction for 14 hours. After centrifugation and washing, dry at 140°C for 2 hours to obtain a micro-nano structure basic ferric ammonium phosphate containing 1 crystalline water. The primary particle size is 30-50nm, the secondary particle size is about 3 microns. The obtained basic ammonium iron phosphate is heat-treated at 400° C. for 10 hours...

Embodiment 3

[0045] Prepare a mixed solution of 0.5mol / L ferrous chloride and ferrous acetate, the mass ratio of the two is 1:1, and add diammonium hydrogen phosphate to the aqueous solution according to the ferrous ion concentration and phosphate ion concentration of 1.2:1 , use ammonia water to adjust the pH of the resulting solution to 5, and keep the temperature at 80°C, and react for 1 hour at a stirring rate of 800rpm; measure hydrogen peroxide with a stoichiometric excess of 50%, and add it dropwise to ferrous chloride, acetic acid In the mixed solution of ferrous iron and diammonium hydrogen phosphate, use ammonia water to adjust the system pH=5 at the same time, keep the temperature at 80°C to continue the reaction for 4 hours after the dropwise addition, and dry at 100°C for 6 hours after centrifugation and washing to obtain The micro-nano structure basic ammonium ferric phosphate containing 2 crystal waters has a primary particle size of 20-30nm and a secondary particle size of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com