Anode material of lithium ion cell and preparation method thereof

A technology for lithium ion batteries and positive electrode materials, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve the problems of insufficient diffusion performance of lithium iron phosphate ions, difficult control and operation, and poor product uniformity, etc., to achieve Good recycling performance, easy control and operation, good product uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] will 2346.5 grams of NH 4 H 2 PO 4 , 3655.2 g FeC 2 O 4 ·2H 2 O, 778.8 g Li 2 CO 3 and 650 grams of glucose and 75 grams of nano-TiO 2 Mixing, adding the mixed material into the ball mill tank, the volume ratio of the ball material is 1:1, sealing the ball mill tank, and continuously ball milling for 12 hours. The ball milled raw material was moved to a high temperature atmosphere furnace, heated to 350°C at a rate of 10°C / min, kept at a constant temperature for 12 hours, then heated to 680°C at a heating rate of 15°C / min, and maintained at this temperature for 24 hours at a constant temperature, Then cool to room temperature with the furnace and take out to obtain LiFePO 4 / C product of cathode material.

[0033] The electrochemical properties of the obtained material were determined by the following methods: 92% of the positive active material, 3% of acetylene black, and 5% of the polyvinylidene fluoride binder were uniformly mixed and then made into a positi...

Embodiment 2

[0035] 2668 g (NH 4 ) 2 HPO 4, 3600g FeC 2 O 4 ·2H 2 O, 770 grams of Li 2 CO 3 and 560 grams of polyacrylamide and 76 grams of fumed nano-SiO 2 Mixing, adding the mixed material into the ball mill tank, the volume ratio of the ball material is 1:1, the ball mill tank is sealed, and the ball mill is continued for 16 hours. The ball-milled raw material was moved to a high-temperature atmosphere furnace, heated to 300°C at a rate of 10°C / min, kept at a constant temperature for 18 hours, then heated to 700°C at a heating rate of 15°C / min, and maintained at this temperature for 24 hours at a constant temperature, Then cool to room temperature with the furnace and take out to obtain LiFePO 4 / C product of cathode material.

Embodiment 3

[0037] Mix 1420 grams of phosphorus pentoxide, 1438 grams of ferrous oxide, 864 grams of lithium hydroxide and 298 grams of polypropylene, add the mixture to a ball mill jar, the volume ratio of the ball to the material is 1:1, seal the ball mill jar, and continuously ball mill 24 Hour. The ball-milled raw material was moved to a high-temperature atmosphere furnace, heated to 300°C at a rate of 10°C / min, kept at a constant temperature for 20 hours, then heated to 650°C at a heating rate of 10°C / min, and maintained at this temperature for 24 hours at a constant temperature, Then cool to room temperature with the furnace and take out to obtain LiFePO 4 / C product of cathode material.

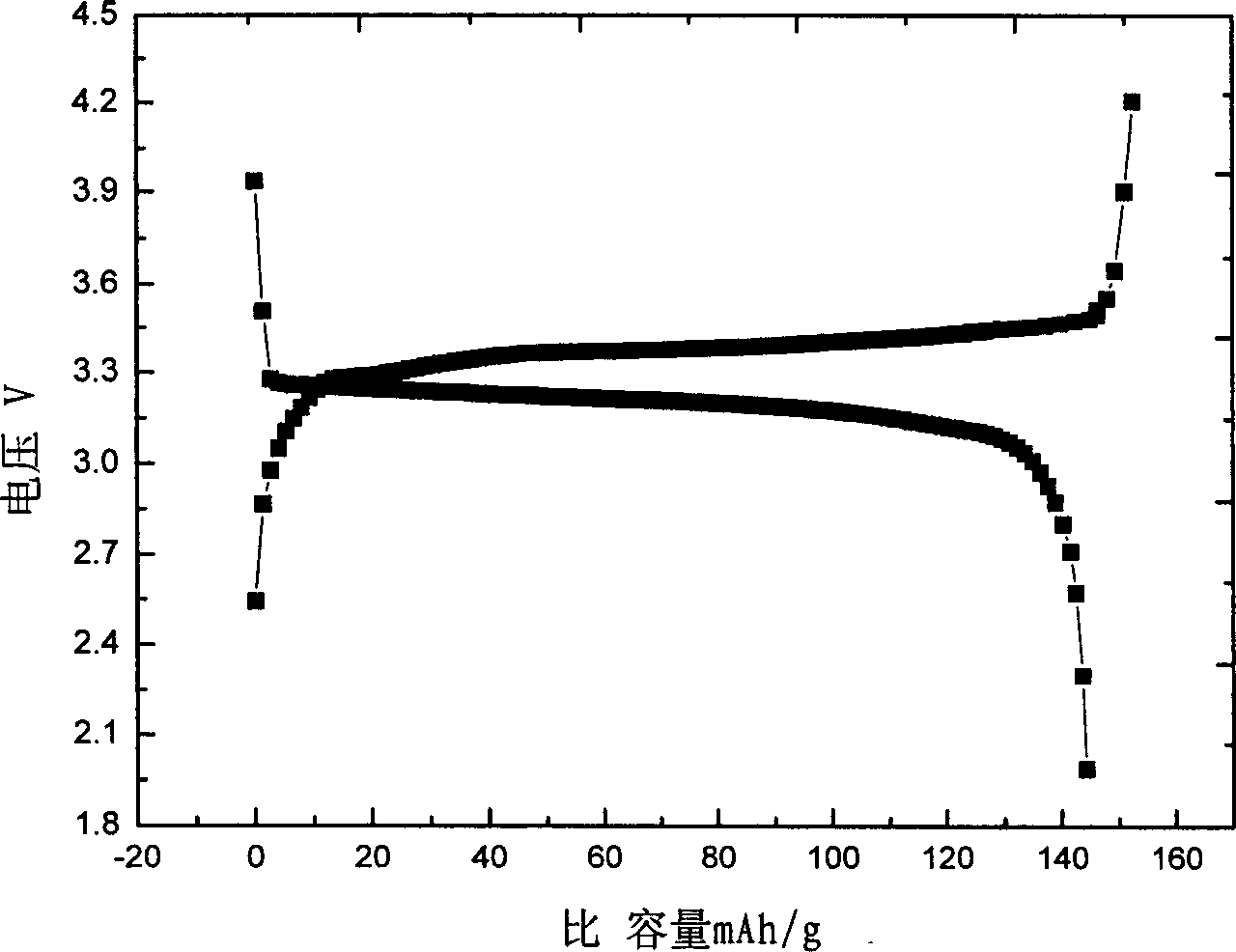

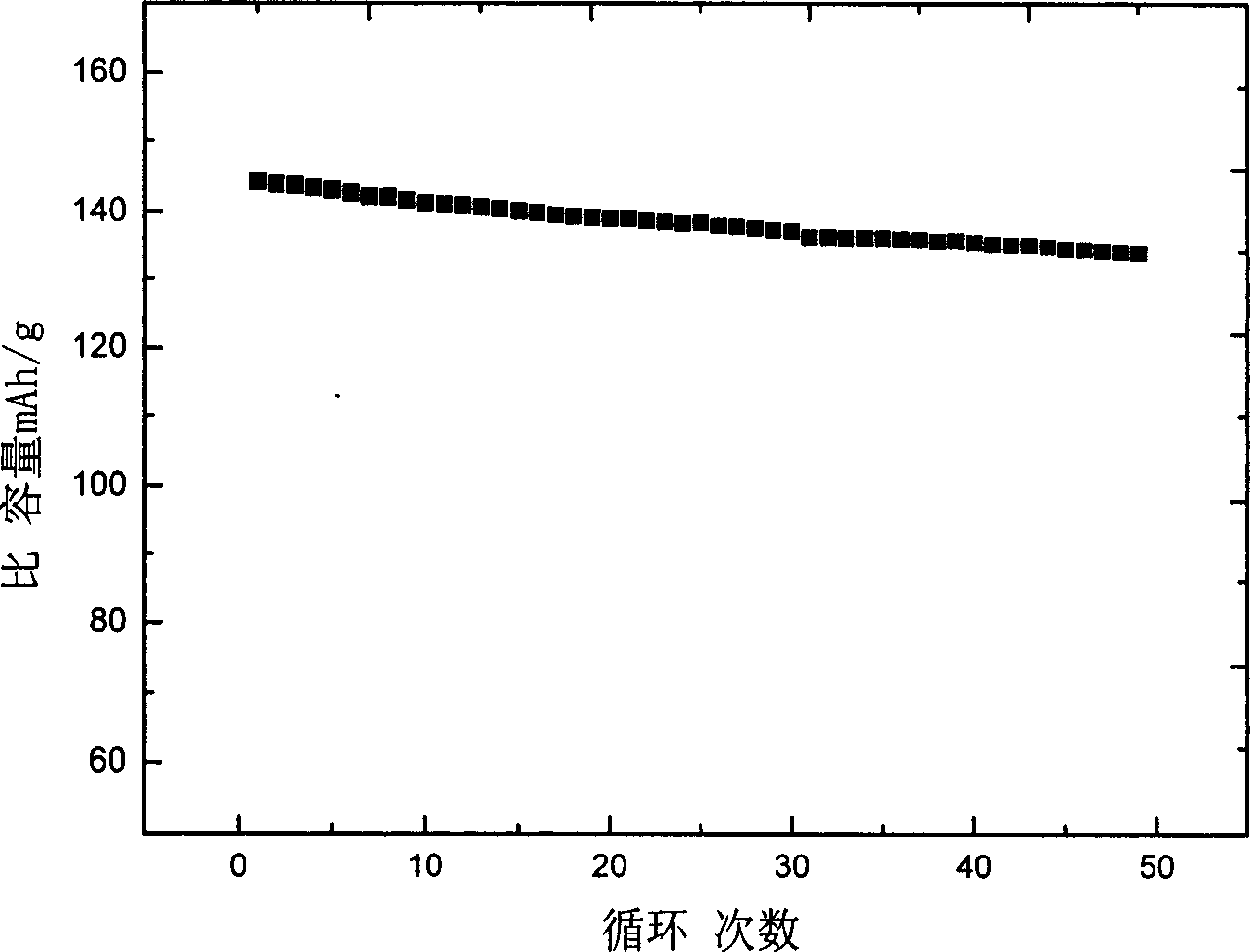

[0038] attached figure 1 It is the charge-discharge curve at 0.5C rate, the voltage range is 2.0-4.2V, and the electrolyte is LiPF 6 , the solvent is EC+DMC (volume ratio is 1:1), and it is charged and discharged at a rate of 0.5C. from the attached figure 1 It can be seen that the LiFePO obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com