Method for uniformly coating carbon on nano lithium iron phosphate

A lithium iron phosphate and carbon coating technology, which is applied to electrical components, battery electrodes, circuits, etc., can solve problems such as uneven particle size, poor electrical conductivity, and inability to fully coat carbon, and achieve good electrical conductivity and high electrical conductivity. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

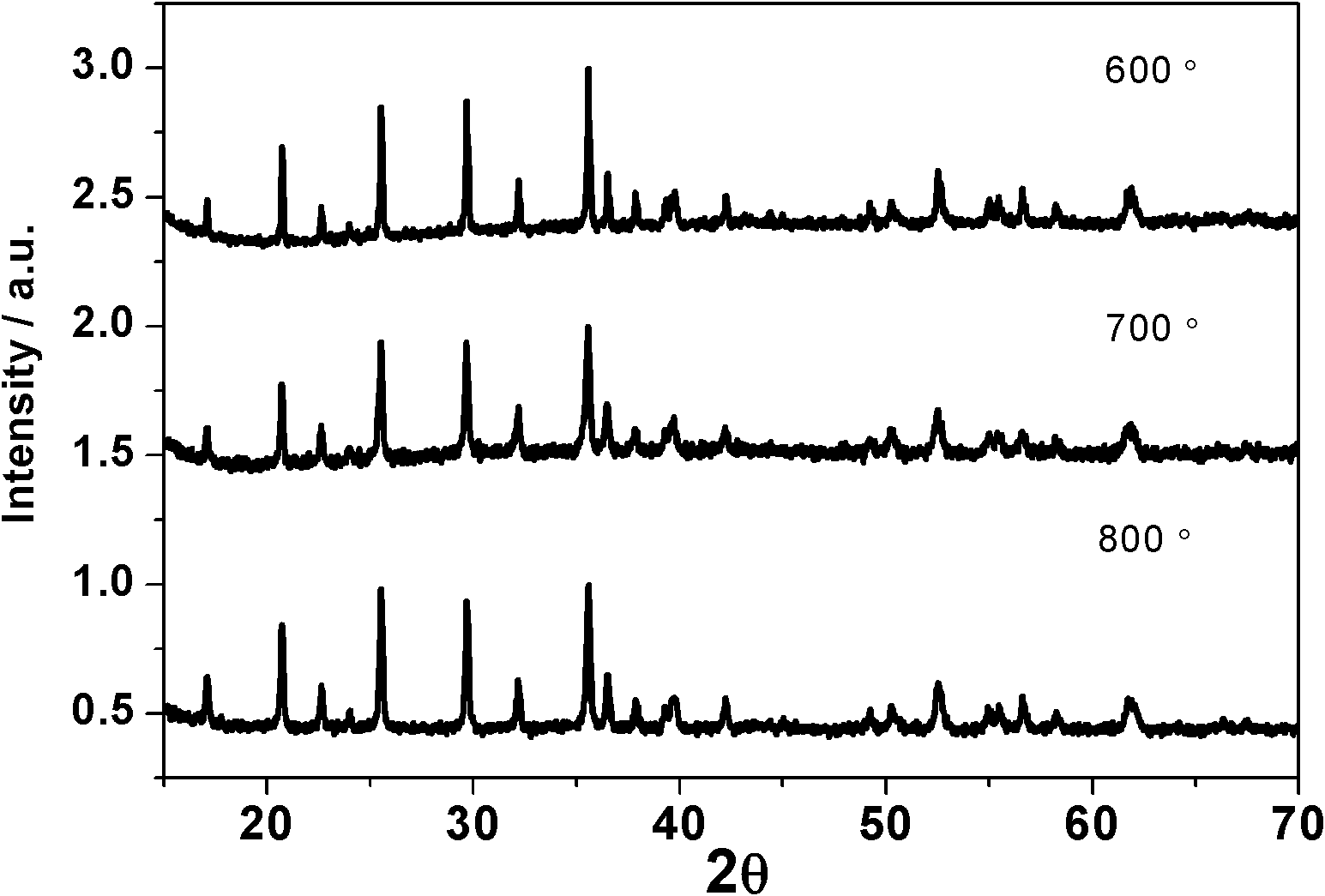

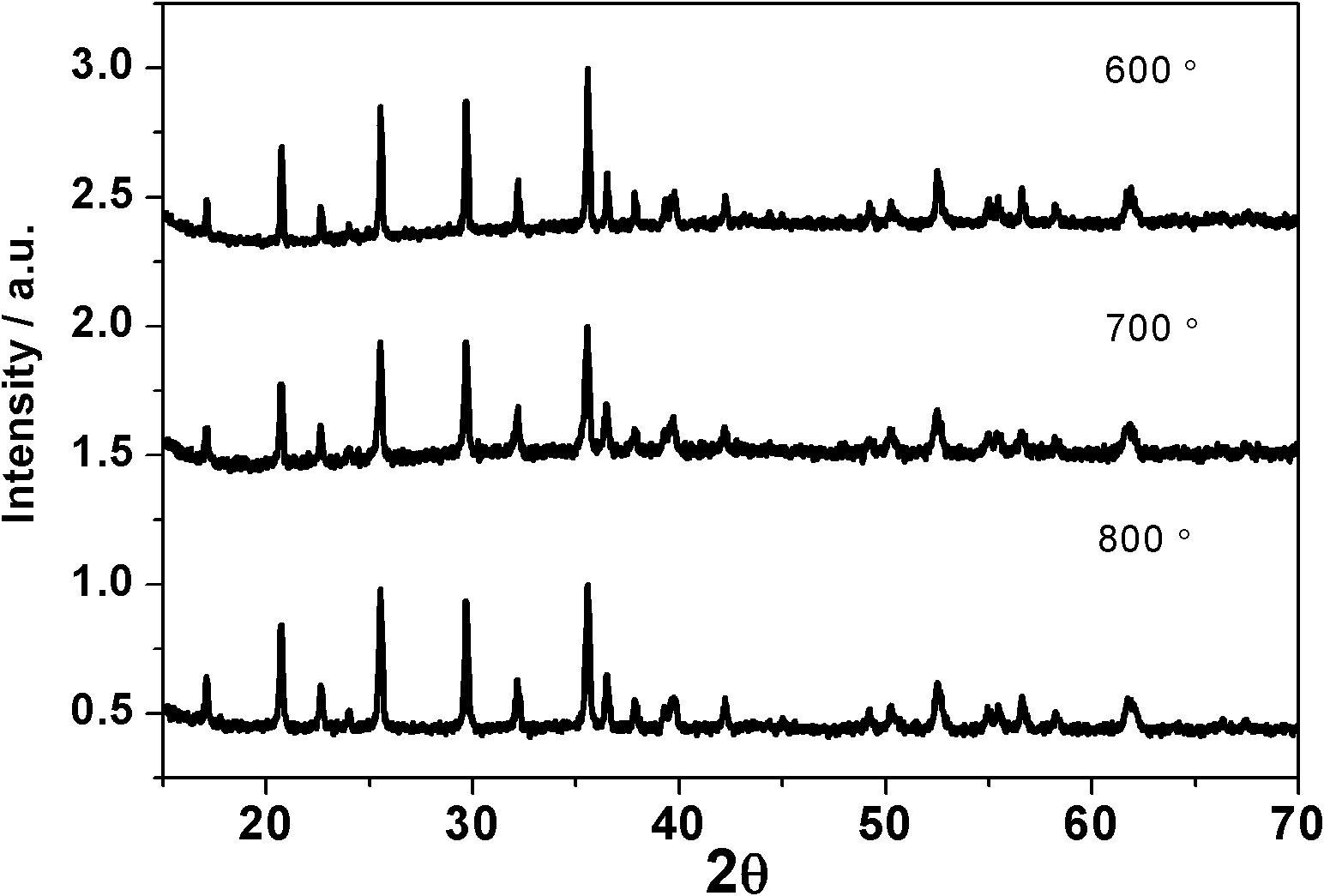

Embodiment 1

[0022] 1) Weigh 1 mol of ferrous sulfate and 1 mol of phosphoric acid (calculated based on the effective content of phosphoric acid at a volume concentration of 85%) in a molar ratio of 1:1, dissolve them in 2000 ml of deionized water, and add 0.1 mol of complexing agent ethylene glycol , Under constant stirring, slowly add 3000ml of 3mol lithium hydroxide solution;

[0023] 2) Continue stirring the above solution in an oil bath at 110°C for 1 hour; until a green precipitate is produced, the green precipitate is suction filtered and washed to obtain a solid product;

[0024] 3) Dry the obtained solid product in a vacuum drying oven at a temperature of 60°C for 6 hours; the dried precursor is ball-milled to obtain a precursor powder with a particle size of 20 nm;

[0025] 4) Dissolve the obtained precursor and nano-scale amorphous carbon black in deionized water at a mass ratio of 1:0.05, stir thoroughly and evenly disperse and mix, and place in a vacuum drying oven at 60°C for 5 hour...

Embodiment 2

[0029] 1) Weigh 2 mol of ferrous chloride and 2 mol of phosphoric acid (calculated based on the effective content of phosphoric acid at a volume concentration of 85%) in a molar ratio of 1:1, dissolve them in 4000 ml of deionized water, and add 0.2 mol of complexing agent ethylene dichloride Alcohol and triethanolamine, slowly add 6000ml of 2mol lithium carbonate solution under constant stirring;

[0030] 2) Continue stirring the above solution in an oil bath at 120°C for 1.5 hours; until a green precipitate is produced, the green precipitate is suction filtered and washed to obtain a solid product;

[0031] 3) Put the obtained solid product in a vacuum drying oven at a temperature of 70°C; dry for 8 hours; ball mill the dried precursor to obtain a precursor powder with a particle size of 50 nm;

[0032] 4) Dissolve the obtained precursor and nano-scale amorphous carbon graphite in deionized water at a mass ratio of 1:0.1, stir thoroughly and evenly disperse and mix, and place them i...

Embodiment 3

[0036] 1) Weigh 1.5 mol of ferrous sulfate and ferrous chloride hydrate, 1.5 mol of phosphoric acid (calculated based on the effective content of phosphoric acid at a volume concentration of 85%) in a molar ratio of 1:1, and dissolve in 3000 ml of deionized water , Add 0.2mol of complexing agent polypropylene ethylene, slowly add 3mol of lithium carbonate and lithium sulfate hydrate solution 4500ml under constant stirring;

[0037] 2) Continue stirring the above solution in an oil bath at 140°C for 2 hours; until a green precipitate is produced, the green precipitate is suction filtered and washed to obtain a solid product;

[0038] 3) Dry the obtained solid product in a vacuum drying oven at a temperature of 80°C for 10 hours; the dried precursor is pulverized by ball milling to obtain a precursor powder with a particle size of 100 nm;

[0039] 4) Dissolve the obtained precursor, nano-scale amorphous carbon graphite and artificial graphite in deionized water at a mass ratio of 1:0.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com