Process for producing homodisperse spherical iron lithium phosphate

A lithium iron phosphate, spherical technology, applied in the field of high-density spherical lithium iron phosphate preparation, can solve the problems of complex preparation process of spherical lithium iron phosphate, slightly poor electrochemical performance, high process control requirements, etc., and achieves low cost of raw materials, vibration and vibration. The effect of high solid density and simple process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

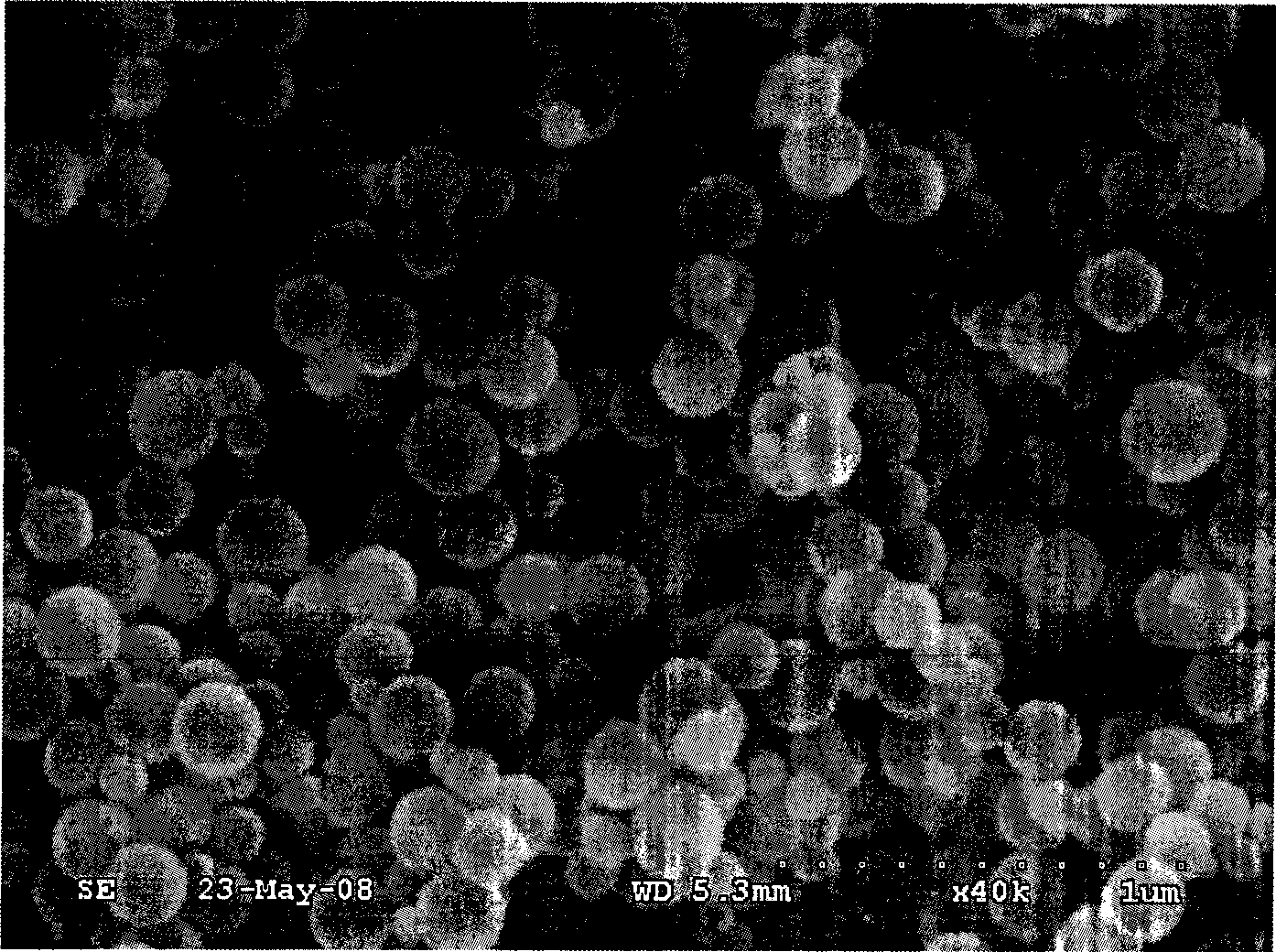

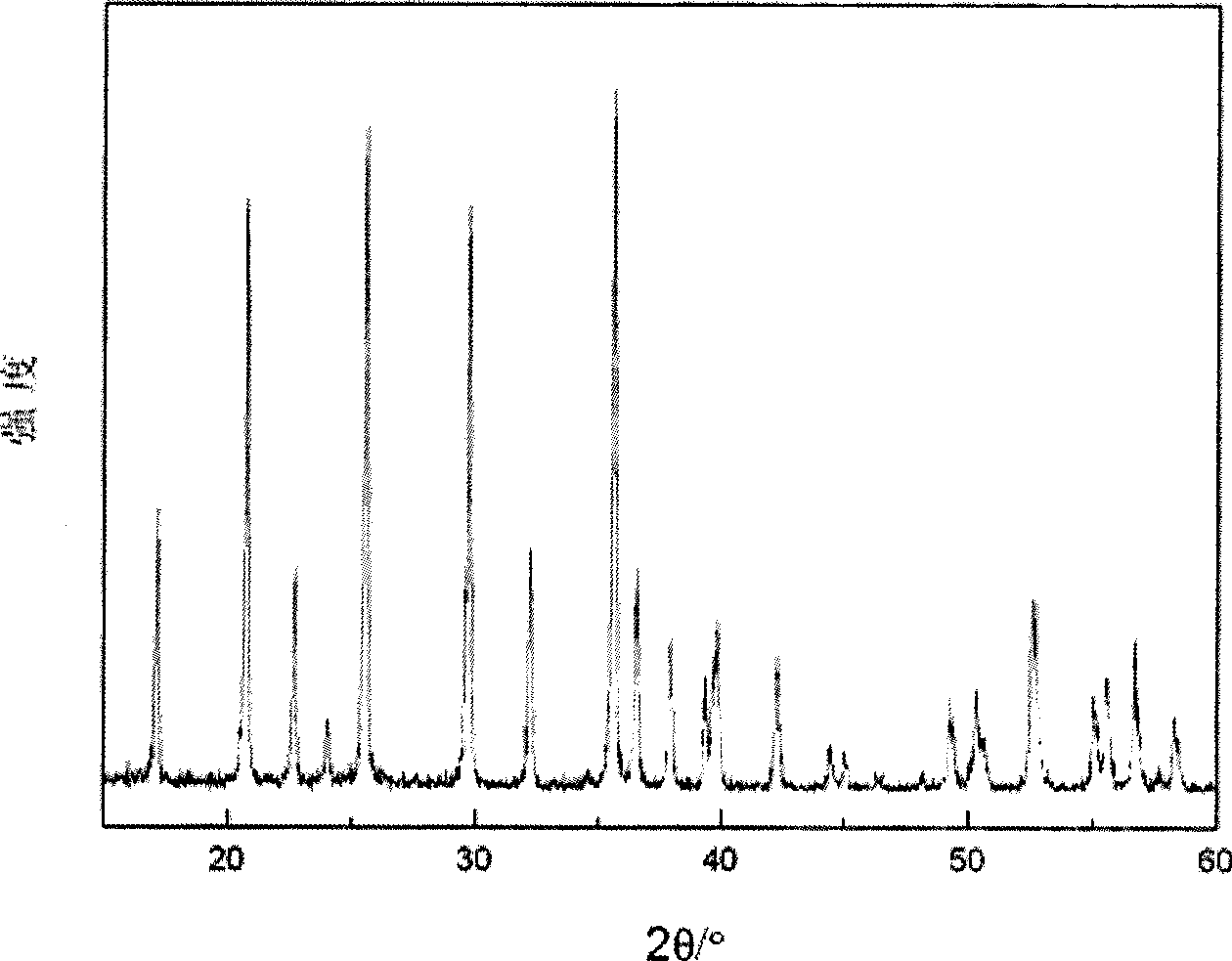

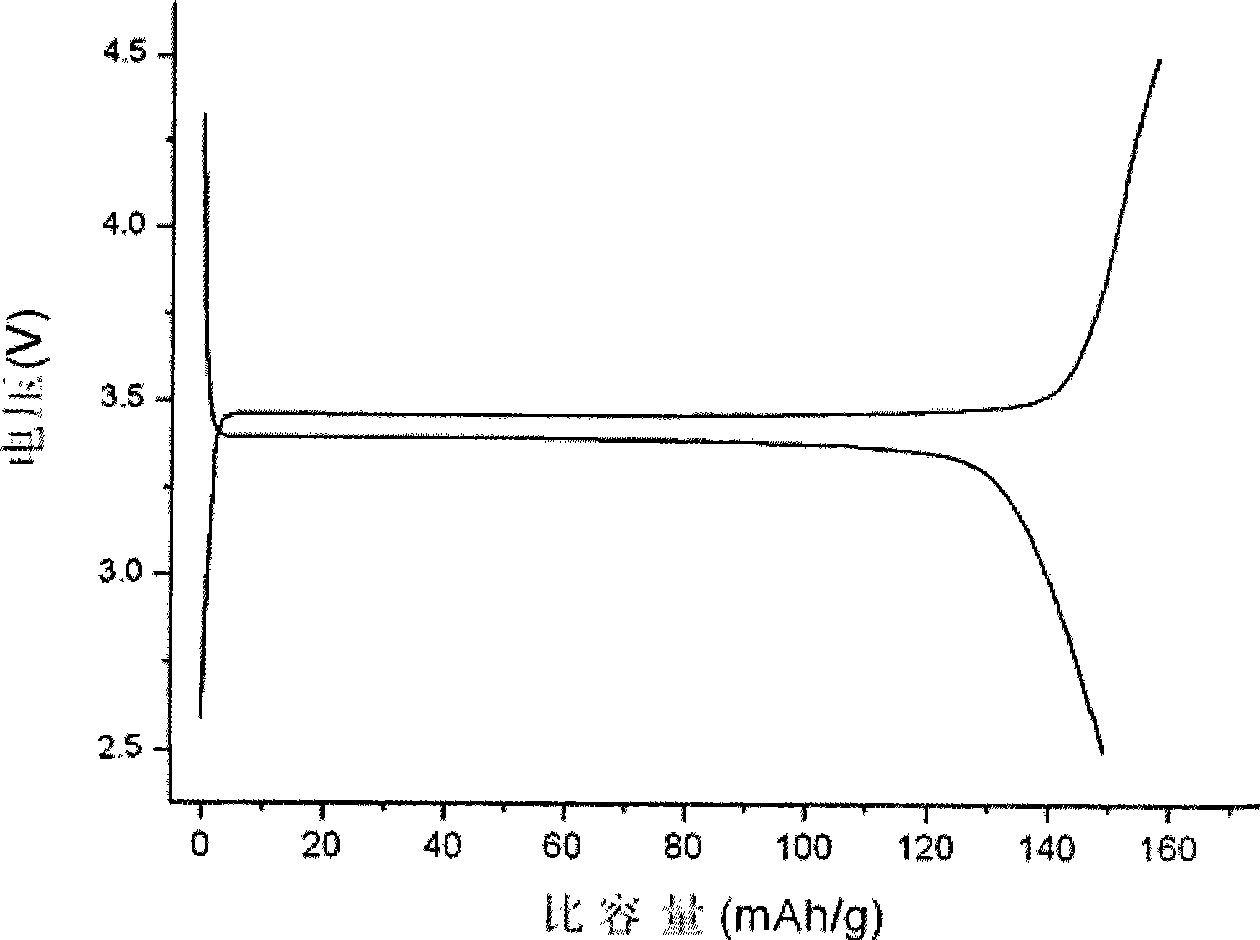

Embodiment 1

[0036] Weigh 4.0544g of ferric chloride, add 300ml of distilled water to obtain iron source solution. Measure 2.153ml of phosphoric acid, weigh 2.1061g of sodium dihydrogen phosphate, and add 300ml of distilled water to obtain a 0.15 mol / L phosphorus source solution. The pH of the phosphorus source solution was adjusted to 1.5 with hydrochloric acid. Slowly add the iron source solution into the phosphorus source solution, and keep stirring to obtain a reaction solution, and keep stirring for one hour. The reaction solution was placed in an airtight container, then placed in a thermostat at 35° C., kept warm for 48 hours, and taken out to obtain a precipitate. The precipitate is separated, washed and dried to obtain uniformly dispersed spherical iron phosphate. Weigh 1.8682g iron phosphate, 0.7389g lithium carbonate, and 2% acetylene black, mix them and mill them in a ball mill for 2 hours. The mixed powder was transferred to a quartz boat, then placed in a tube furnace, und...

Embodiment 2

[0041] Weigh 27.0290 g of ferric trichloride and add 200 ml of distilled water to obtain an iron source solution. Measure 14.35ml of phosphoric acid, weigh 14.0409g of sodium dihydrogen phosphate, and add 200ml of distilled water to obtain a 1.5 mol / L phosphorus source solution. The pH of the phosphorus source solution was adjusted to 1.8 with hydrochloric acid. Slowly add the iron source solution into the phosphorus source solution, and keep stirring to obtain a reaction solution, and keep stirring for one hour. The reaction solution was placed in an airtight container, and then placed in a thermostat at 90° C., kept warm for 30 minutes, and then taken out to obtain a precipitate. The precipitate is separated, washed and dried to obtain uniformly dispersed spherical iron phosphate. Weigh 9.3410g iron phosphate, 2.0980g lithium hydroxide (LiOH H 2 O), 0.8764g glucose, 1.4245g magnesium nitrate (Mg(NO 3 ) 2 ·H 2 O), after mixing, ball milled for 5 hours in a ball mill. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com