Preparation method of Cu1.8+xS binary thermoelectric material

A thermoelectric material, cu1.8 technology, applied in copper sulfide, nanotechnology and other directions, can solve problems such as unreported thermoelectric performance, and achieve the effects of less time-consuming, energy saving, and short preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

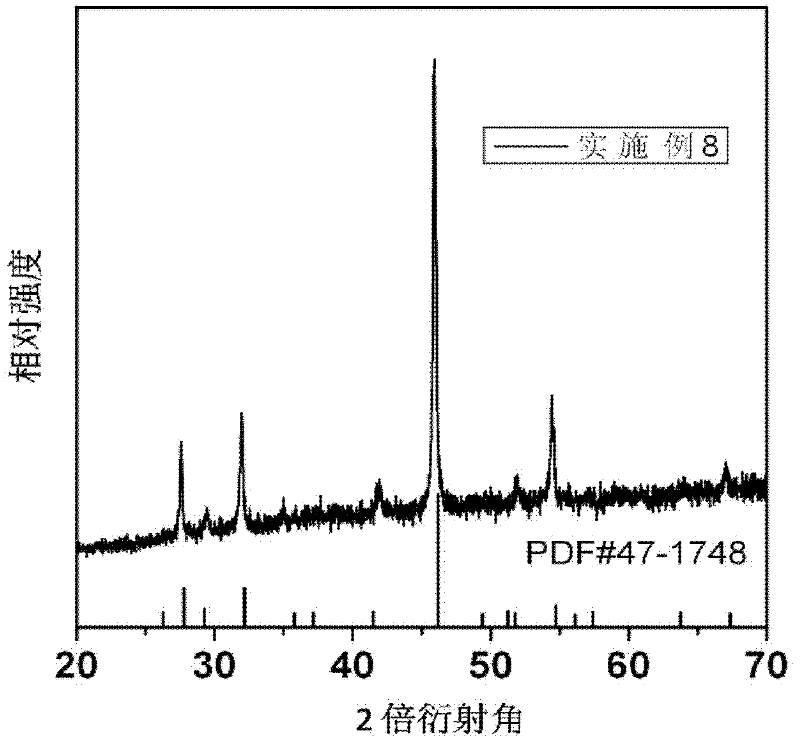

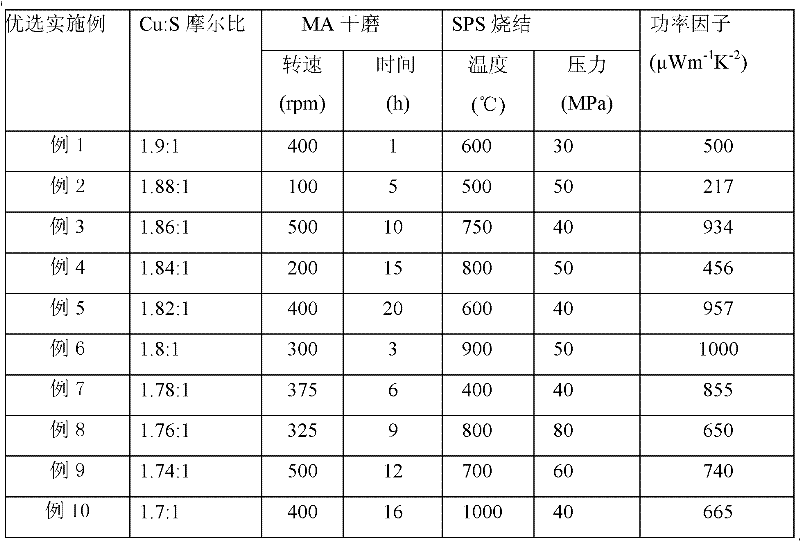

[0008] Cu was first prepared by mechanical alloying method 1.8+x S (-0.1≤x≤0.1) binary nano-powder, the method is that Cu powder (mass percentage is greater than 99.9%) and S powder (mass percentage is greater than 99.5%) according to the general chemical formula Cu 1.8+x After S (-0.1≤x≤0.1) is proportioned, it is mixed and placed in a planetary ball mill, and mechanically alloyed under the protection of inert gas argon to obtain Cu 1.8+x S alloy powder. The powder is subjected to spark plasma sintering to obtain a bulk thermoelectric material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com