Manufacturing method based on photocuring 3D printing technology and used for circuit board

A 3D printing and manufacturing method technology, applied in the directions of additive manufacturing, processing manufacturing, manufacturing tools, etc., can solve the problem of relying on expensive injection molding equipment and molds, not suitable for manufacturing small and medium-scale customized products, etc., to reduce production equipment and molds. The effect of investment, shortened production cycle and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

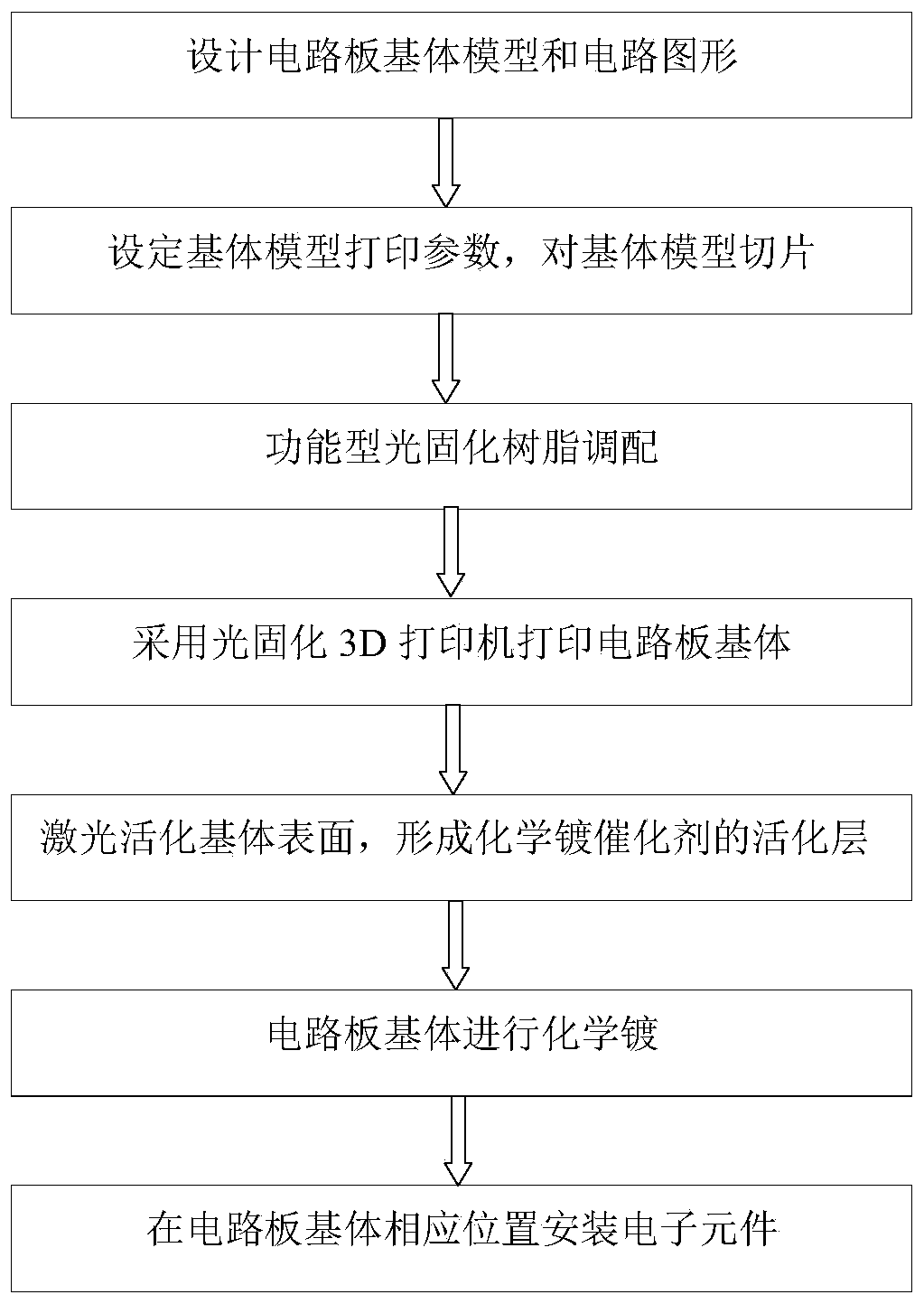

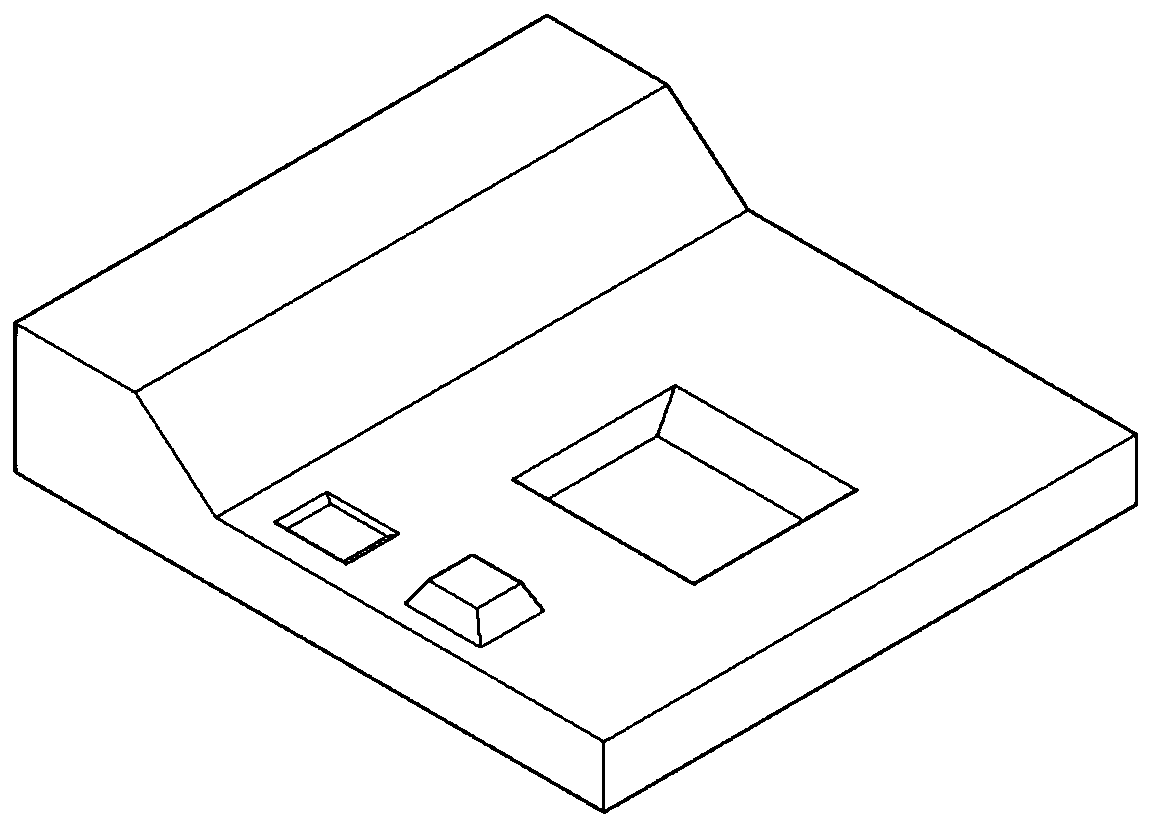

[0020] Example 1: If figure 1 — Image 6 , a method for manufacturing a circuit board based on photocuring 3D printing technology, comprising the following steps:

[0021] (1) Use computer-aided design software to design the three-dimensional circuit matrix model and circuit graphics respectively. The three-dimensional circuit matrix is exported as an STL file format. This format uses triangular grids to represent the outer contour shape of the object. It is a manufacturing method for 3D printing. 3D graphics file format for technical services. The circuit graphics are exported in PLT format, which is a drawing format file;

[0022] (2) Import the three-dimensional circuit matrix model into the 3D printing slicing software, set the printing parameters such as layer thickness and exposure time of each layer, slice the model, and obtain the digital code for driving the photocuring 3D printer. The code is SLC Format or cross-sectional image compression file package, which ca...

example 2

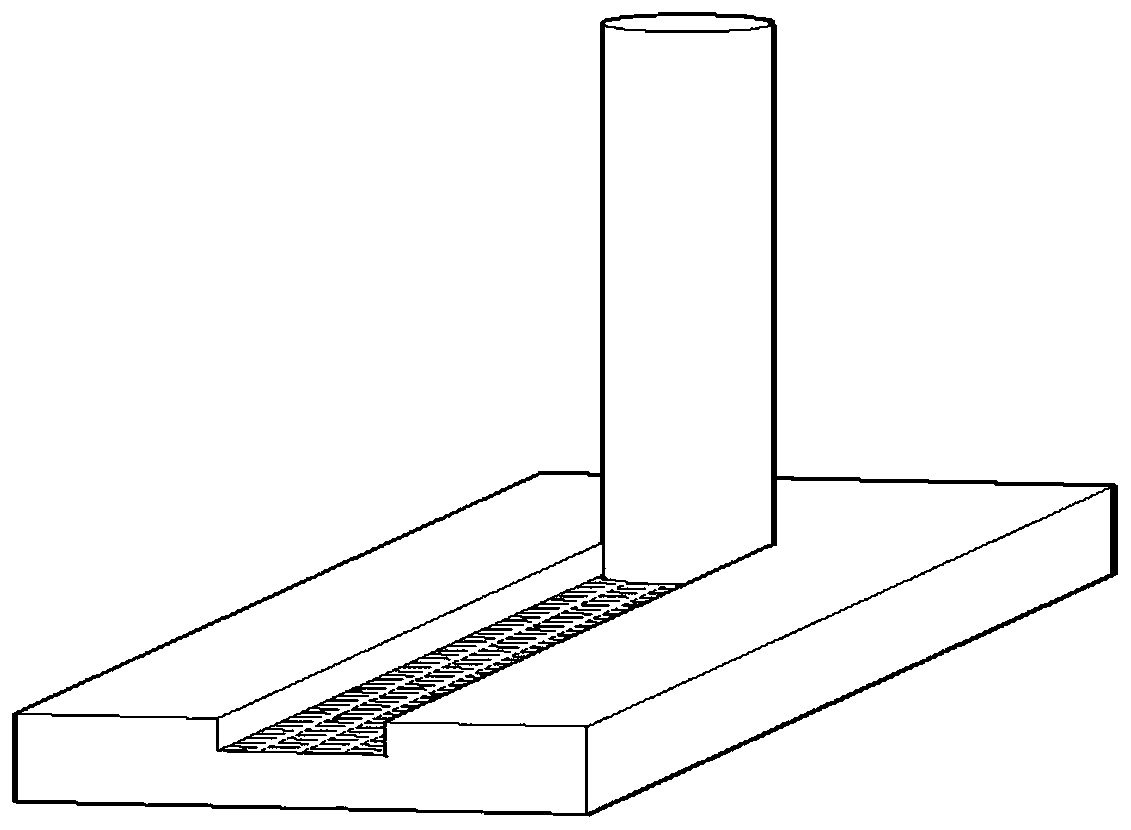

[0028] Example 2: see figure 1 , 3 , 4 and 7, the design and manufacturing method based on photocuring 3D printing technology proposed by the present invention has a high degree of processing freedom, so it can be applied not only to the manufacture of three-dimensional three-dimensional circuits, but also to the manufacture of two-dimensional circuit boards.

[0029] (1) Two-dimensional circuit board matrix model and circuit graphic design: use computer-aided design software to design three-dimensional three-dimensional circuit matrix model and circuit graphics, in which the two-dimensional circuit board matrix is exported as an STL file format, which is represented by a triangular grid The outline shape of an object is a three-dimensional graphics file format serving 3D printing manufacturing technology. The circuit graphics are exported in PLT format, which is a drawing format file;

[0030] (2) Substrate model slicing: Import the two-dimensional circuit board substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com