Method for preparing nanometer ferrous phosphate lithium /carbon composite material

A lithium iron phosphate and carbon composite material technology, applied in electrode manufacturing, electrical components, battery electrodes, etc., can solve problems such as difficulty in LiNiO2 synthesis, unsafe overcharge, impossible large-capacity battery application, and structural instability. , to achieve the effect of improving electrochemical performance, excellent electrochemical performance, and inhibiting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

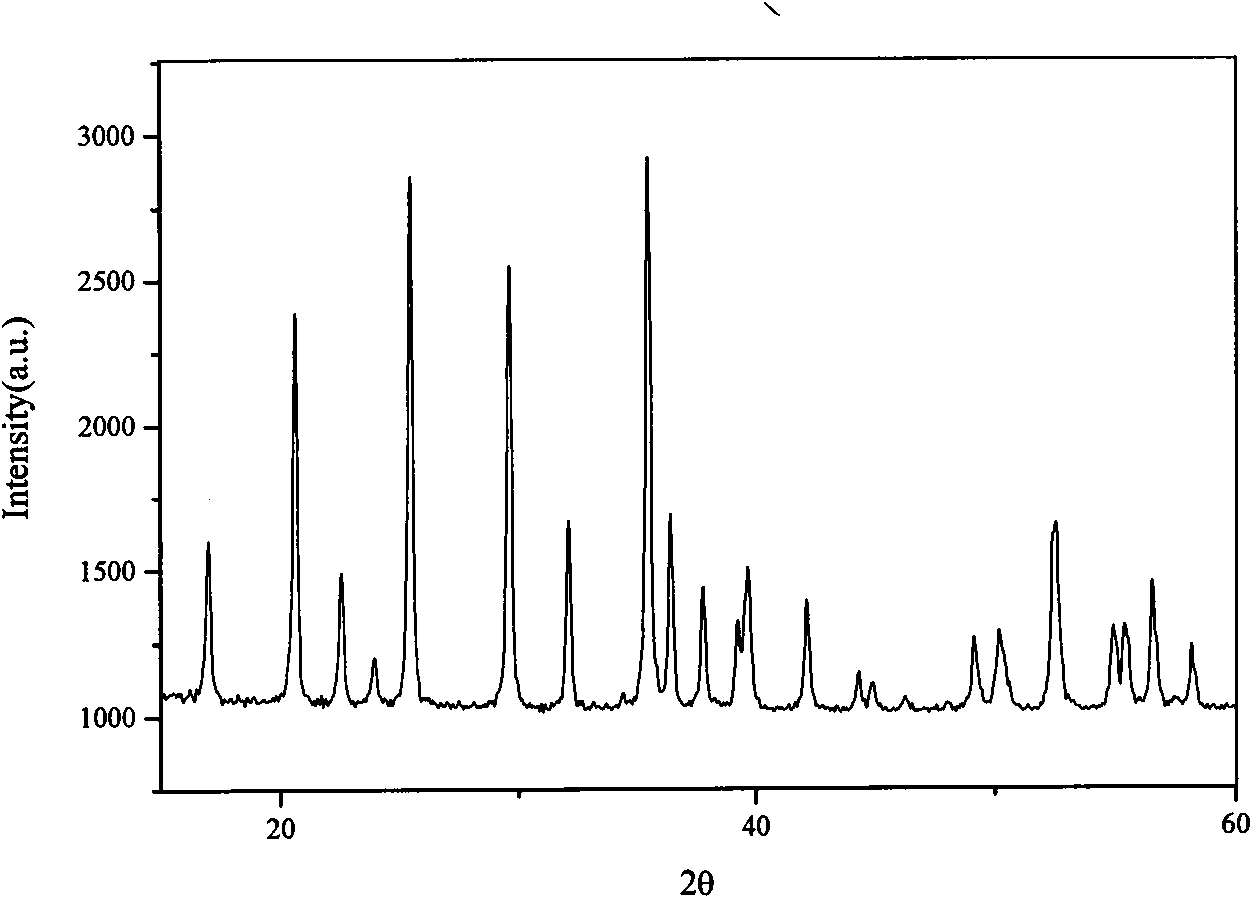

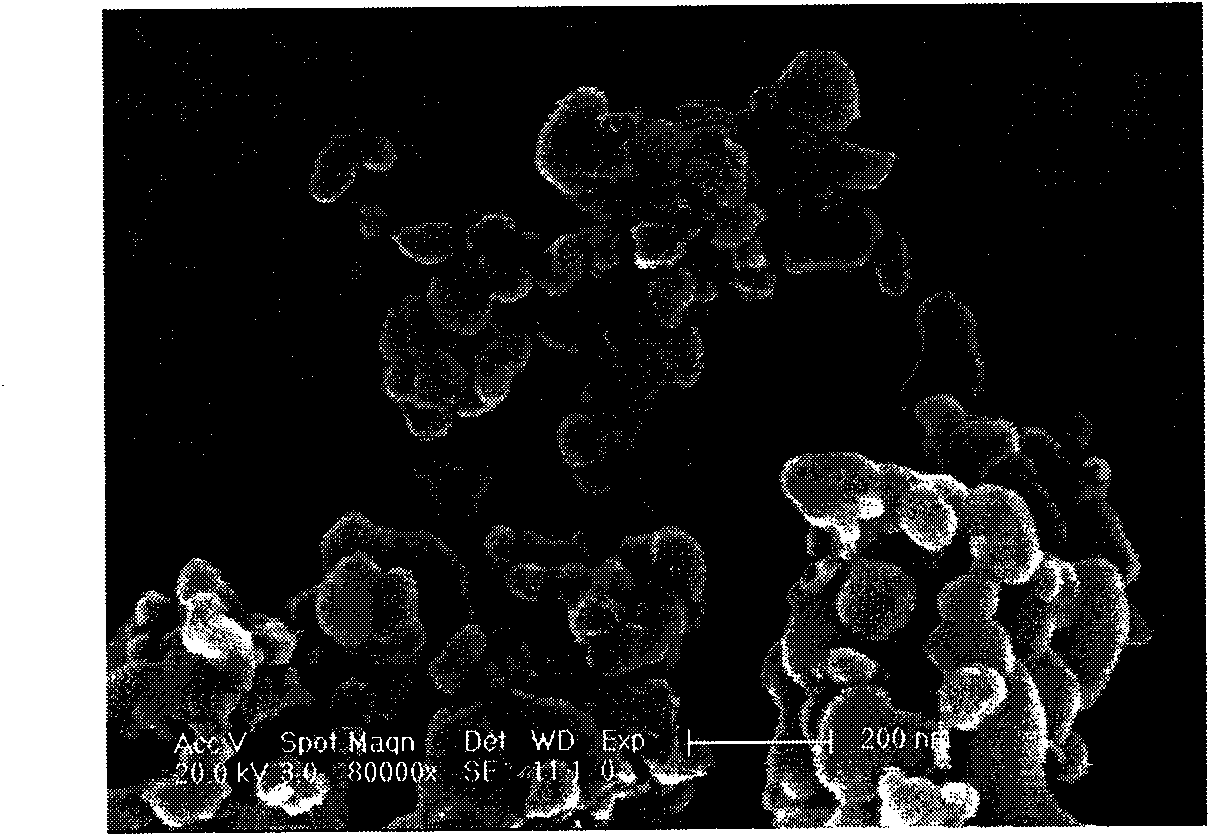

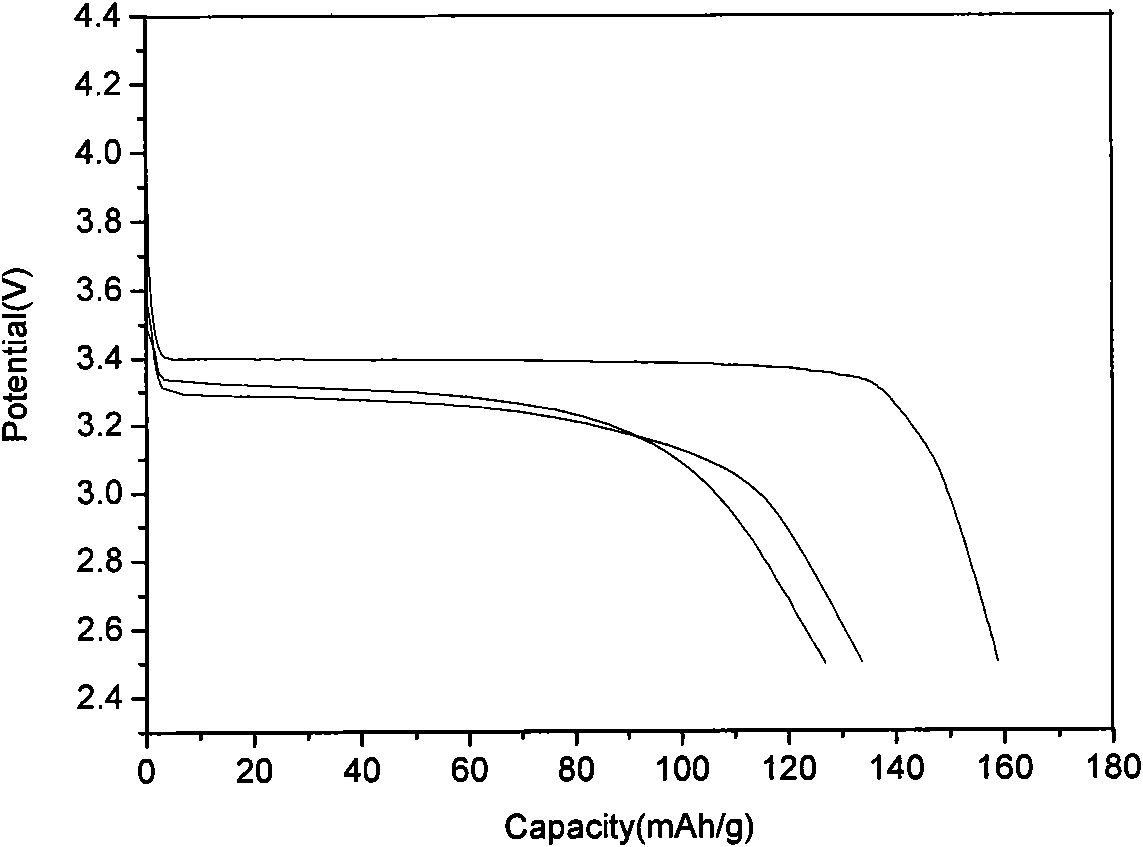

Embodiment 1

[0022] After directly mixing ferrous sulfate, lithium dihydrogen phosphate and nickel acetate according to the molar ratio of Fe:Li:P:Ni 0.9:1:1:0.1, add 10% polyacrylamide (mass percentage relative to lithium iron phosphate ), milled in an appropriate amount of absolute ethanol at 200r / min for 10 hours, dried and then heated in a nitrogen atmosphere at a rate of 5°C / min, stayed at 200°C for 5 hours, and then heated to 500°C for 15 hour, and then cooled naturally to obtain a nanoscale lithium iron phosphate / carbon composite material.

Embodiment 2

[0024] Ferrous chloride, lithium hydroxide, phosphoric acid and chromium trioxide are directly mixed according to Fe: Li: P: Cr molar ratio 0.97: 1: 1: 0.03, then add 5% polyethylene glycol (relative to ferrous phosphate mass percentage of lithium), ball milled in an appropriate amount of acetone for 5 hours at 200r / min, and after drying, heat up in a nitrogen atmosphere at a heating rate of 5°C / min, stay at 250°C for 3 hours, and then heat up to 600°C to keep the temperature After 12 hours, it was naturally cooled to obtain a nanoscale lithium iron phosphate / carbon composite material.

Embodiment 3

[0026] After directly mixing ferrous oxalate, lithium carbonate, phosphoric acid and magnesium acetate according to the molar ratio of Fe:Li:P:Mg 0.99:1:1:0.01, add 10% polyvinyl alcohol (mass percentage relative to lithium iron phosphate) , ball milled in an appropriate amount of distilled water at 200r / min for 8 hours, after drying, heat up in a nitrogen atmosphere at a rate of 5°C / min, stay at 290°C for 5 hours, then raise the temperature to 700°C for 5 hours, and then Cool naturally to obtain nanoscale lithium iron phosphate / carbon composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com