Sludge superheated vapor drying system of two-stage paddle dryer and drying process thereof

A paddle dryer and superheated steam technology, applied in dehydration/drying/thickened sludge treatment, incinerator, lighting and heating equipment, etc., can solve the problems of equipment investment increase, low efficiency, large energy consumption, etc., to achieve Improved drying efficiency, reduced consumption, and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

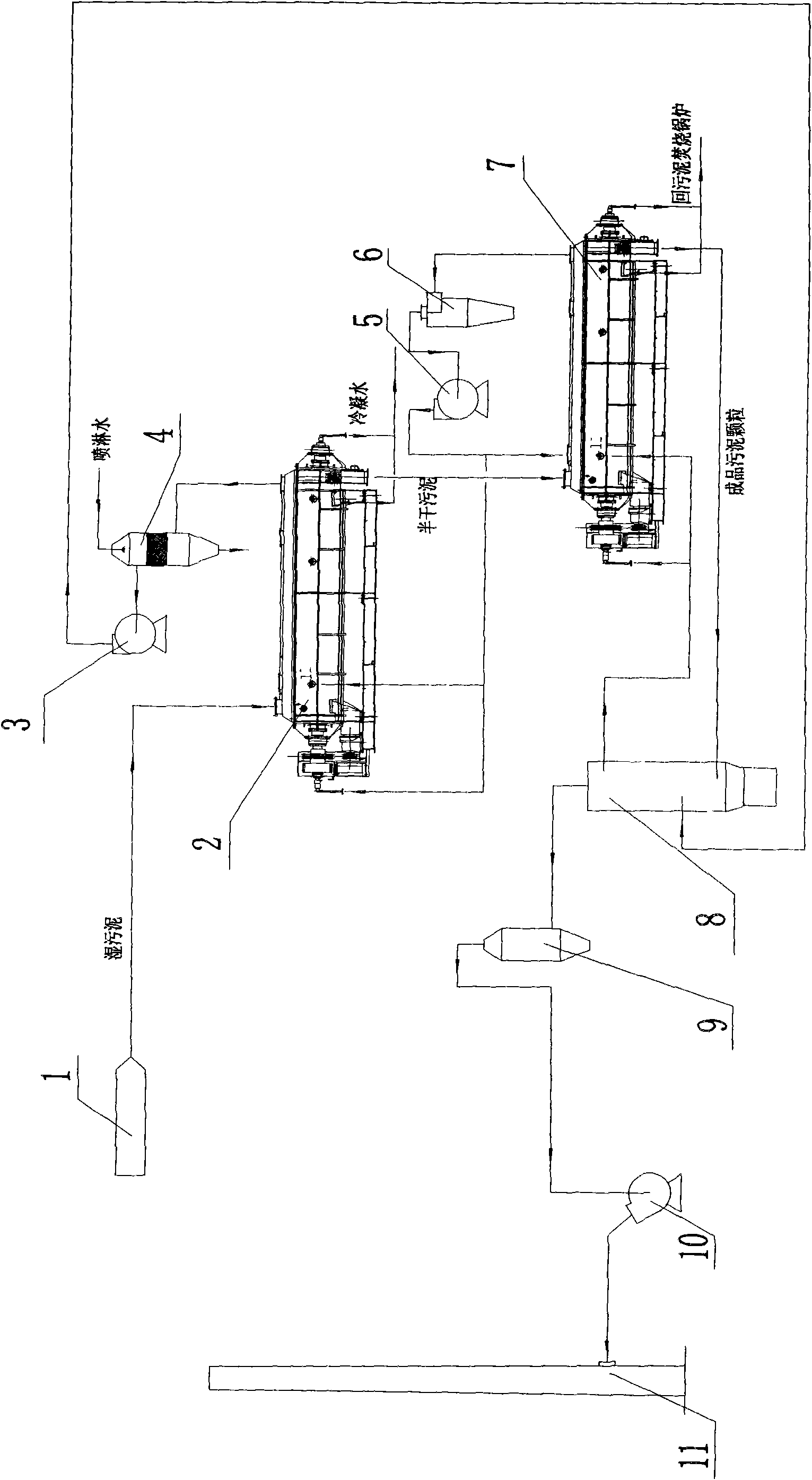

[0032] Such as figure 1 As shown, a dual-stage paddle dryer sludge superheated steam drying system includes a primary paddle dryer 2 and a secondary paddle dryer 7, and the sludge pump 1 is connected to the primary paddle dryer through a pipeline. 2, the discharge port of the primary paddle dryer 2 is connected with the feed port of the secondary paddle dryer 7, and the discharge port of the secondary paddle dryer 7 is connected with the sludge incineration boiler 8 The inlet is connected; the air outlet of the first-stage paddle dryer 2 is connected with the washing tower 4, the induced draft fan A3 and the sludge incineration boiler 8 in turn through the pipeline; the air outlet of the second-stage paddle dryer 7 is connected with the cyclone dust collector 6 , the cyclone dust collector 6 is respectively connected to the air inlet of the secondary b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com